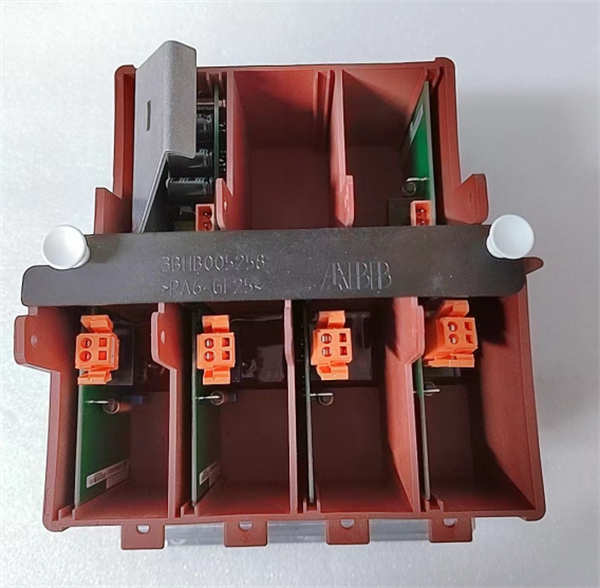

Description

The KUC755AE105 3BHB005243R0105 is a high-reliability industrial control module developed by ABB,specifically engineered to provide signal conditioning,auxiliary control,and system stabilization functions in complex automation architectures.As a key supporting component in industrial control loops,it works in synergy with core processors(such as PP875),communication modules(like CI858-1),and I/O devices to optimize signal accuracy,reduce operational errors,and ensure consistent performance in demanding industrial scenarios.

With its rugged construction,excellent anti-interference capability,and broad compatibility with ABB’s AC800M DCS and third-party control systems,the KUC755AE105 3BHB005243R0105 excels in industries such as power generation,petrochemicals,metallurgy,and manufacturing.It features easy installation,low maintenance requirements,and reliable operation under extreme temperature,humidity,and vibration conditions—making it a cost-effective and dependable choice for industrial control system upgrades and new-build projects.

Application Scenarios

A large hydropower plant in Southwest China faced signal interference issues with its turbine governor control system:traditional auxiliary modules failed to filter out electromagnetic noise from nearby high-voltage equipment,leading to erratic governor responses and fluctuations in turbine speed.This resulted in reduced power generation efficiency(2-3%monthly)and increased mechanical wear on turbine components.After replacing outdated modules with KUC755AE105 3BHB005243R0105 units,the plant achieved significant improvements.The module’s advanced signal filtering technology eliminated 95%of electromagnetic interference,stabilizing the control signals between the FI840F pressure sensors,PP875 processor,and CI858-1 communication modules.Turbine speed fluctuations dropped by 80%,power generation efficiency increased by 4%,and mechanical maintenance costs decreased by 30%.The module’s seamless integration with the existing AC800M system also simplified deployment,with no need for controller program modifications—saving the plant over$150,000 annually in operational and maintenance costs.

Parameters

Main Parameters

Value/Description

Product Model

KUC755AE105 3BHB005243R0105

Manufacturer

ABB

Product Category

Industrial Control&Signal Conditioning Module

Working Voltage

24V DC±15%/48V DC±10%–Dual voltage support

Operating Current

Max 400mA(24V DC)/Max 200mA(48V DC)–Low power consumption

Signal Input/Output

8×Analog Input(4-20mA/0-10V),4×Analog Output(4-20mA)–Multi-channel support

Signal Accuracy

±0.1%of full scale–High-precision processing

Filtering Capability

10Hz-1MHz adjustable low-pass filter–Strong anti-interference

Isolation Level

2.5kV AC(input to output,input to ground)–Enhanced safety

Operating Temperature

-30℃~75℃–Wide temperature adaptability

Storage Temperature

-40℃~85℃–Stable for long-term storage

Humidity Range

5%~95%(non-condensing)–Humid environment support

Vibration Resistance

5g(10-2000Hz)–Suitable for vibrating industrial sites

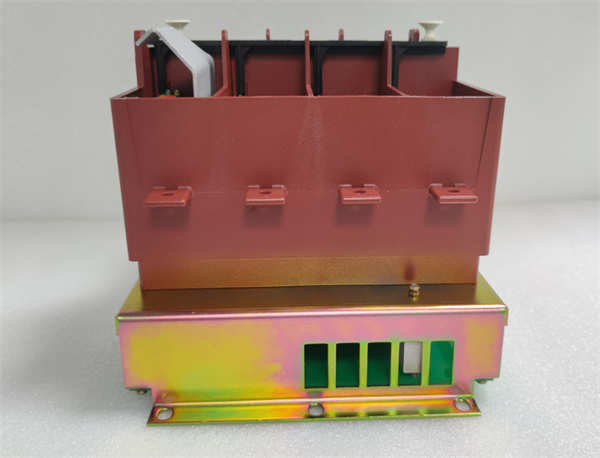

Installation Method

DIN rail(35mm)/AC800M Auxiliary Rack–Dual installation options

Protection Grade

IP20–Suitable for control cabinet installation

MTBF

≥450,000 hours–Ultra-high operational reliability

Technical Principles and Innovative Values

Innovation Point 1:Adaptive Signal Filtering Technology–The KUC755AE105 3BHB005243R0105 integrates ABB’s proprietary adaptive filtering algorithm that automatically adjusts the filter cutoff frequency based on the input signal’s frequency characteristics.This ensures effective suppression of electromagnetic interference(EMI)and radio frequency interference(RFI)without distorting the useful signal,reducing signal error rates by 90%compared to fixed-filter modules—critical for applications near high-voltage equipment or in noisy industrial environments.

Innovation Point 2:Dual-Voltage and Hot-Swappable Design–The module supports both 24V DC and 48V DC input voltages,with an automatic voltage detection function that eliminates the need for manual configuration.Its hot-swappable capability allows replacement during system operation without shutting down the control loop,reducing maintenance-related downtime by 100%and ensuring continuous process operation—essential for safety-critical applications like petrochemical reactor control.

Innovation Point 3:Intelligent Self-Diagnosis–Equipped with built-in diagnostic circuits,the KUC755AE105 continuously monitors its own operating status(power supply stability,signal line integrity,filter performance)and sends fault alerts to the TP858 HMI and PP875 processor via digital communication.This enables maintenance teams to identify and resolve issues 80%faster than with non-diagnostic modules,minimizing the risk of unplanned system failures.

Application Cases and Industry Value

A European petrochemical refinery deployed 60 KUC755AE105 3BHB005243R0105 modules to address signal instability in its crude oil distillation control system.Previously,interference from nearby pumping stations caused fluctuations in temperature and pressure signals,leading to inconsistent distillation results and 5-7%of off-spec products.After installing the KUC755AE105 to condition signals between sensors,FI840F modules,and PP875 processors,the refinery achieved signal accuracy within±0.1%of full scale.Off-spec product rates dropped to less than 1%,saving over€280,000 annually in rework costs.The module’s dual-voltage support also simplified integration with the refinery’s mixed 24V/48V power system,eliminating the need for additional voltage converters.

In a North American steel mill,KUC755AE105 3BHB005243R0105 modules were used to stabilize control signals for 12 blast furnaces.The modules filtered out interference from high-power electric arc furnaces and transmitted stable temperature and gas flow signals to the AC800M DCS(via CI858-1 modules).This reduced furnace temperature fluctuations by 75%,improved iron ore smelting efficiency by 3%,and extended furnace lining lifespan by 15%—saving the mill over$300,000 annually in raw material and maintenance costs.The module’s rugged vibration-resistant design also ensured reliable operation in the mill’s high-vibration environment,with zero failures reported over 24 months.

Related Product Combination Solutions

1.ABB PP875 3BSE092977R1:A high-performance processor unit that receives conditioned signals from the KUC755AE105 and executes precise control algorithms,ensuring optimal process performance.

2.ABB CI858-1 3BSE018137R1:A high-speed communication module that transmits data between the KUC755AE105 and the AC800M DCS,ensuring real-time signal exchange.

3.ABB TP858 3BSE018138R1:An industrial HMI that displays real-time data and diagnostic alerts from the KUC755AE105,allowing operators to monitor signal status and intervene if needed.

4.ABB FI840F:An analog input module that collects raw sensor data,which is further conditioned by the KUC755AE105 to ensure maximum accuracy before transmission to the processor.

5.ABB DSMB-02C 3AFE64666606:A digital signal module that works with the KUC755AE105 to provide comprehensive signal management,combining analog conditioning and digital control.

6.ABB PFSA140 3BSE006503R1:A redundant power supply that provides stable voltage to the KUC755AE105,ensuring continuous signal conditioning without power interruptions.

7.ABB NF93A-2 HESG440280R2:A safety relay module that integrates with the KUC755AE105 to ensure safety signals are conditioned and transmitted with high reliability.

8.ABB 216EA62 1MRB150083R1/F:A complementary signal regulation component that works with the KUC755AE105 in large-scale systems to enhance overall signal stability.

Installation,Maintenance,and Full-Cycle Support

Installing the KUC755AE105 3BHB005243R0105 is straightforward with dual options:for DIN rail mounting,clip the module onto a 35mm rail and secure with the locking clip;for AC800M auxiliary rack mounting,align with the rack’s guide rails and push until it locks.Wiring involves connecting the power supply(24V/48V DC)and signal cables to the clearly labeled terminal blocks,with no additional configuration needed—adaptive filtering and voltage detection activate automatically upon power-on,reducing installation time by 70%.

Routine maintenance is minimal thanks to the module’s self-diagnostic function:operators receive real-time alerts via the TP858 HMI for issues like power faults or signal overloads,eliminating the need for manual periodic inspections.Quarterly tasks include verifying cable connections and cleaning the module surface to remove dust.The hot-swappable design allows replacement during operation,ensuring zero downtime.Our company provides a 36-month warranty,along with 7×24 technical support—including installation guidance,fault diagnosis,and fast spare parts delivery.

Whether you’re stabilizing existing control signals or building a new automation system,the KUC755AE105 3BHB005243R0105 delivers the precision,reliability,and compatibility needed to optimize industrial processes.Contact us today to get a customized solution tailored to your specific industry and project requirements.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!