Product Overview

The**ABB AZ20/112112221112E/STD**is a high-security,solenoid-locked safety interlock switch designed to enforce machine safety by controlling access to hazardous areas and preventing unintended machine operation.As a core component of industrial safety systems,this switch is engineered to monitor the status of machine guards(e.g.,doors,covers)and interrupt power to dangerous machinery when guards are opened,protecting operators from risks such as moving parts,electrical hazards,or chemical exposure.Compliant with international safety standards(EN ISO 14119,IEC 60947-5-1),it meets Category 4/PLe safety requirements,making it suitable for critical applications in manufacturing,power generation,and petrochemical industries.

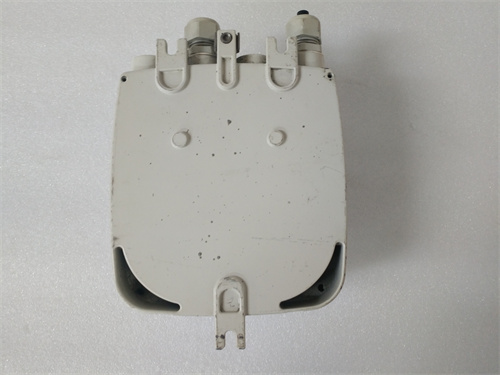

Featuring a robust metal housing,IP67 protection rating,and solenoid locking mechanism,the**ABB AZ20/112112221112E/STD**is built to withstand the harsh conditions of industrial environments—including dust,water jets,vibration,and extreme temperatures.The solenoid locking function ensures the machine guard remains closed until the switch receives a safe signal from the control system,preventing unauthorized access during machine operation.Equipped with multiple normally closed(NC)and normally open(NO)contacts,the switch offers flexible integration with ABB’s AC 800M DCS,PLCs,and emergency stop systems,ensuring seamless communication with existing automation infrastructure.

Designed for ease of installation and maintenance,the**ABB AZ20/112112221112E/STD**supports DIN rail or surface mounting and features a clear LED status indicator for quick visual verification of switch status(locked,unlocked,fault).It also includes built-in diagnostic features to detect wiring faults or solenoid failures,transmitting alerts to the control system and HMI panels(e.g.,ABB CP405 A0)for timely troubleshooting.The switch’s compatibility with standard safety relays and programmable safety controllers further enhances its versatility,making it a reliable choice for both new installations and retrofits of existing safety systems.

Technical Specifications

Parameter Name

Parameter Value

Product Model

ABB AZ20/112112221112E/STD

Manufacturer

ABB

Product Type

Solenoid-Locked Safety Interlock Switch

Safety Category

EN ISO 13849-1:Category 4;SIL 3(IEC 61508);PLe(Performance Level e)

Locking Mechanism

Solenoid-Operated,Spring-Assisted Mechanical Lock

Electrical Ratings

AC-15:230V AC,6A;DC-13:24V DC,6A

Contact Configuration

4 Contacts(2 NC,2 NO)-Changeover Contacts

Solenoid Voltage

24V DC(Standard);110V AC/230V AC(Optional)

Locking Force

1500N(Mechanical Retention Force)

Actuator Type

Separable Actuator(Key-in-Head Design),Compatibility with AZ20 Actuator Series

Protection Rating

IP67(IEC 60529);NEMA 4X

Operating Temperature

-25℃to 70℃

Humidity Range

0-95%RH(Non-Condensing)

Vibration Resistance

10-55Hz,10g(IEC 60068-2-6)

Shock Resistance

50g(11ms Duration,IEC 60068-2-27)

Mounting Type

DIN Rail Mount(35mm),Surface Mount(Optional)

Housing Material

Die-Cast Aluminum(Housing),Stainless Steel(Actuator)

Dimensions(W×H×D)

45mm×105mm×75mm

Weight

0.5kg

Diagnostic Features

LED Status Indicator(Red:Locked,Green:Unlocked,Amber:Fault),Solenoid Fault Detection,Wiring Fault Monitoring

Certifications

CE,UL,CSA,ATEX Zone 2,IECEx,CCC

Main Features and Advantages

High Safety Performance:The**ABB AZ20/112112221112E/STD**meets the highest safety standards(Category 4,PLe,SIL 3),ensuring reliable protection against machine-related hazards.The solenoid-locked mechanism prevents the machine guard from being opened while the machinery is in operation,and the redundant contact configuration(2 NC,2 NO)ensures a fail-safe response—even if one contact fails,the remaining contacts maintain the safety interlock,minimizing the risk of unintended machine startup.

Robust Design for Harsh Environments:Constructed with a die-cast aluminum housing and stainless steel actuator,the switch offers exceptional durability and resistance to physical damage.Its IP67 protection rating ensures it operates reliably in environments with dust,water jets,and chemical splashes—ideal for installation in automotive plants,food processing facilities,and offshore platforms.The switch also withstands extreme temperatures(-25℃to 70℃)and high vibration,ensuring consistent performance in turbine halls and manufacturing lines.

Flexible Integration with Automation Systems:Designed to work seamlessly with ABB’s AC 800M DCS,AC 500 PLC,and safety relays,the switch requires no custom adapters for integration.Its 4-changeover contacts(2 NC,2 NO)support both safety and control circuits,enabling it to send status signals to the DCS and trigger machine shutdowns when guards are opened.The switch also integrates with emergency stop systems,providing an additional layer of safety for operators in critical situations.

Easy Installation and Maintenance:The**ABB AZ20/112112221112E/STD**supports standard 35mm DIN rail mounting,simplifying installation in control cabinets.The separable actuator design allows for easy replacement without rewiring,reducing maintenance time.The clear LED status indicator(red for locked,green for unlocked,amber for fault)enables operators to quickly verify switch status,while built-in diagnostic features detect solenoid failures and wiring faults—alerts are transmitted to the DCS and displayed on HMI panels(e.g.,ABB CP405 A0)for timely troubleshooting.

Secure Solenoid Locking:The 1500N mechanical retention force of the solenoid lock ensures the machine guard remains closed until the switch receives a safe signal from the control system,preventing unauthorized access.The solenoid operates on 24V DC(with AC options available)and features a spring-assisted mechanical backup—if power to the solenoid is lost,the switch remains locked,maintaining safety even during power fluctuations.This dual-layer locking mechanism provides peace of mind in critical applications.

Application Field

In manufacturing and automotive industries,the**ABB AZ20/112112221112E/STD**is used to secure machine guards on robotic workcells,welding equipment,and assembly lines.It prevents operators from accessing hazardous areas while robots are in motion,and the solenoid lock ensures the guard remains closed until the robot has come to a complete stop.The switch integrates with ABB’s AC 500 PLC to trigger immediate shutdowns if the guard is opened,reducing the risk of serious injuries.

In power generation plants(thermal,hydro,nuclear),the switch is installed on turbine enclosures,generator covers,and high-voltage equipment guards.It ensures operators cannot access these hazardous areas while the equipment is energized,and the IP67 rating and extreme temperature resistance make it suitable for installation in turbine halls and outdoor switchyards.The switch integrates with the AC 800M DCS to send status signals and trigger emergency shutdowns if the guard is opened,protecting both operators and equipment.

In the oil&gas and petrochemical industries,the**ABB AZ20/112112221112E/STD**is used to secure guards on pumps,compressors,and chemical processing units.Its ATEX Zone 2 certification allows safe operation in hazardous areas with flammable vapors,while the robust design withstands exposure to oil,chemicals,and water.The switch ensures guards remain closed during operation,preventing leaks and protecting operators from exposure to hazardous substances.It integrates with safety relays to shut down equipment if the guard is opened,minimizing the risk of fires or explosions.

In food and beverage processing facilities,the switch is installed on mixer enclosures,conveyor guards,and filling machine covers.Its IP67 rating and corrosion-resistant materials(stainless steel actuator)make it suitable for washdown environments,where it is exposed to water and cleaning chemicals.The switch ensures operators cannot access moving parts during processing,and the solenoid lock prevents accidental guard opening—helping facilities comply with food safety regulations(e.g.,FDA,EU 10/2011)and maintain a safe working environment.

Related Products

-ABB AC 800M:DCS controller that integrates the AZ20 switch for centralized safety monitoring and control.

-ABB CP405 A0 1SAP500405R0001:HMI panel that displays status and fault alerts from the AZ20 switch.

-ABB XO08R2 1SBP260109R1001:Digital output module triggered by the AZ20 switch to shut down machinery.

-ABB Safety Relay SR200:Relay that works with the AZ20 switch to enhance safety circuit redundancy.

-ABB AC 500 PLC:Compact PLC that integrates the AZ20 switch for machine-level safety control.

-ABB AZ20 Actuator Series:Replacement actuators for the AZ20 switch,available in various designs for different guard types.

-ABB TB830 Terminal Block:Terminal block for wiring the AZ20 switch to safety relays and control systems.

-ABB F800 Surge Protector:Accessory for protecting the AZ20 switch from voltage spikes in industrial circuits.

Installation and Maintenance

Pre-installation preparation:Before installing the**ABB AZ20/112112221112E/STD**,verify compatibility with the target safety system(e.g.,safety relay,PLC)and confirm the installation location meets environmental requirements(temperature:-25℃to 70℃,protection rating:IP67).Ensure the machine is powered off and follow lockout/tagout(LOTO)procedures to prevent electrical hazards.Gather tools including a torque screwdriver(0.5-0.8 N·m),wire strippers,and a multimeter for testing.

Mounting and wiring:Mount the switch on a 35mm DIN rail in the control cabinet or surface-mount it near the machine guard using the optional mounting bracket.Connect the solenoid to the 24V DC power supply(ensure correct polarity)and wire the contacts to the safety relay or PLC—use twisted-pair shielded cables to prevent electromagnetic interference.Mount the actuator on the machine guard,ensuring alignment with the switch for smooth operation.Test the locking mechanism by closing the guard and verifying the switch locks(red LED on)and unlocks(green LED on)when the control system sends the appropriate signal.

Maintenance recommendations:Perform monthly visual inspections to check for loose wiring,damage to the housing or actuator,and proper LED status indication.Clean the switch and actuator with a soft,lint-free cloth—avoid using harsh chemicals that could damage the housing.Test the locking mechanism quarterly by opening and closing the guard to ensure smooth operation,and verify the fail-safe function by disconnecting the solenoid power(the switch should remain locked).Use the DCS diagnostic tools to review fault logs and address alerts such as wiring faults or solenoid failures promptly.Replace the actuator if it shows signs of wear to maintain reliable operation.

Product Guarantee

We guarantee that every**ABB AZ20/112112221112E/STD**safety switch is 100%authentic,sourced directly from ABB,and accompanied by original safety certification documents,test reports,and user manuals.The switch comes with a 36-month warranty covering manufacturing defects in hardware and compliance with safety standards.During the warranty period,we provide free replacement for faulty units and 24/7 technical support from ABB’s safety engineering team.Our team offers on-site installation guidance,safety system integration training,and troubleshooting services to ensure the switch delivers reliable operator protection throughout its service life.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!