Product Overview

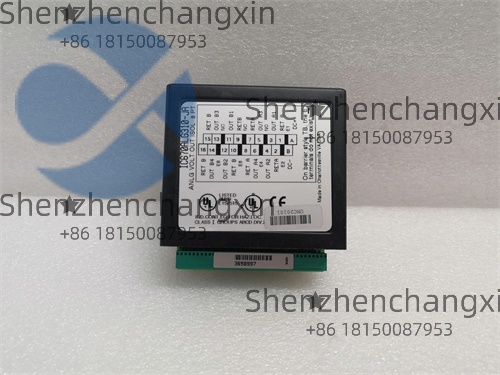

The GE IC660ELB912G is a high-performance,8-channel analog input module designed for the GE Fanuc Series 90-30 PLC platform and compatible with the later PACSystems RX3i architecture via adapter.As part of GE’s Block I/O family for the Genius I/O bus,this module delivers precise acquisition of standard industrial current signals—primarily 4–20 mA—from field transmitters such as pressure,temperature,flow,and level sensors.Each channel features individual signal conditioning,galvanic isolation,and advanced diagnostics,making the GE IC660ELB912G a cornerstone component in process automation systems where measurement accuracy and system reliability are non-negotiable.

Engineered for demanding environments like refineries,power stations,and chemical plants,the GE IC660ELB912G incorporates robust protection against electrical noise,ground loops,and transient surges—common challenges in electrically noisy industrial settings.Its support for open-wire detection ensures immediate fault reporting if a sensor loop is broken,preventing undetected process deviations.Furthermore,the module’s compatibility with HART-enabled transmitters(when used with appropriate interface hardware)allows for digital parameter access alongside the analog signal,enhancing asset management capabilities.Even as newer platforms emerge,the GE IC660ELB912G remains widely deployed and actively maintained due to its proven field performance and seamless integration into legacy and hybrid control architectures.

Technical Specifications

Product Model|IC660ELB912G

Manufacturer|General Electric(GE)/Emerson

Product Type|Analog Input Module(Block I/O)

Number of Channels|8 differential inputs

Input Signal Range|4–20 mA(sink mode),scalable to 0–20 mA

Input Impedance|250Ωper channel

Isolation|500 VDC between field and logic sides,channel-to-channel isolated

Resolution|14-bit A/D conversion

Accuracy|±0.1%of full scale at 25°C

Update Rate|~5 ms per module(Genius bus dependent)

Diagnostics|Open-wire detection,overrange/underrange indication

Mounting|DIN rail or panel mount(with optional bracket)

Operating Temperature|0°C to+60°C

Certifications|CE,UL,CSA,IEC 61010

Main Features and Advantages

High-fidelity signal acquisition:The IC660ELB912G employs precision 14-bit analog-to-digital conversion with low-drift circuitry,ensuring consistent measurement accuracy across temperature variations and long-term operation.This fidelity is critical in applications like boiler drum level control or reactor temperature monitoring,where even minor signal errors can compromise safety or product quality.

Advanced diagnostics for predictive maintenance:Beyond basic signal reading,the IC660ELB912G continuously monitors each loop for open-wire conditions—a frequent failure mode in aging plants.When detected,it sets a status bit accessible via the PLC logic,enabling early intervention before a process upset occurs.This diagnostic capability reduces unplanned downtime and supports condition-based maintenance strategies.

Robust noise immunity and grounding flexibility:Each channel on the IC660ELB912G is galvanically isolated from the backplane and from adjacent channels,effectively breaking ground loops that cause signal drift or instability.Combined with shielded terminal blocks and common-mode rejection>120 dB,this design ensures clean signal integrity even when routed alongside motor cables or near VFDs.

Seamless integration into existing control ecosystems:Designed for the Genius I/O bus,the IC660ELB912G connects directly to Series 90-30 CPUs or to PACSystems RX3i via an IC695CHS012 baseplate adapter.Configuration is performed through Proficy Machine Edition or Logicmaster software,with automatic calibration and scaling.Its modular form factor allows mixed I/O racks containing digital,analog,and specialty modules,optimizing cabinet space and system cost.

Application Field

The IC660ELB912G is extensively used in continuous process industries where analog signal integrity directly impacts operational safety and efficiency.In oil and gas upstream facilities,it reads pressure and differential pressure signals from wellhead chokes and separator vessels to maintain safe operating envelopes.In combined-cycle power plants,the IC660ELB912G acquires steam temperature,condenser vacuum,and feedwater flow data for turbine protection and efficiency optimization.

In water and wastewater treatment,the module interfaces with pH,turbidity,and chlorine residual analyzers to automate chemical dosing.Similarly,in pharmaceutical and food processing,it supports validated processes requiring traceable,accurate temperature and pressure logging.The IC660ELB912G is also a common choice for modernizing legacy Bailey INFI 90 or Westinghouse systems—where analog I/O is migrated to a GE-based front-end while retaining higher-level control logic.Its reliability in SIL-rated safety instrumented functions(when deployed in redundant configurations)further extends its use into critical shutdown systems.

Related Products

IC660ELB914G:4-channel isolated thermocouple/mV input module in the same Block I/O family

IC660ELB922G:8-channel analog output module(4–20 mA)for control valve positioning

IC693PWR321:Power supply for Series 90-30 PLC racks hosting IC660ELB912G

IC695CHS012:RX3i baseplate adapter enabling IC660ELB912G use in PACSystems

IC660ACC001:Terminal block kit with removable connectors for quick field wiring

IC660BBD022:16-point discrete input module for complementary digital sensing

IC660ELR121:Remote I/O scanner for distributed Genius bus networks

Proficy Machine Edition:Configuration and programming software for GE/PACSystems platforms

Installation and Maintenance

Pre-installation preparation:Before installing the IC660ELB912G,confirm compatibility with your rack backplane(Series 90-30 or RX3i with adapter)and ensure the Genius bus network is properly terminated with 120-ohm resistors at both ends.Verify that field wiring uses twisted-pair,shielded cable,with shields grounded at the controller end only to avoid ground loops.Check that all 4–20 mA transmitters share a common reference potential or are fully floating to prevent current path conflicts.

Maintenance recommendations:The IC660ELB912G requires no routine calibration but should be periodically inspected for terminal tightness and signs of moisture or corrosion,especially in outdoor or high-humidity enclosures.Use the built-in open-wire diagnostic flags in your PLC logic to trigger maintenance alerts rather than relying solely on operator observation.If replacing a failed unit,ensure firmware and configuration match the original—module replacement in redundant systems must follow proper synchronization procedures.Store spare IC660ELB912G modules in static-safe packaging away from magnetic fields and extreme temperatures to preserve internal electronics.

Product Guarantee

We guarantee that every IC660ELB912G we supply is 100%authentic,thoroughly tested for channel functionality,isolation integrity,and communication responsiveness on a live Genius bus.Each unit undergoes simulated open-wire and overrange testing to validate diagnostic features.Backed by a 12-month warranty and supported by engineers with decades of GE automation experience,our IC660ELB912G modules are ready for immediate deployment in mission-critical applications.We provide full technical documentation and configuration guidance to ensure seamless integration,reaffirming our commitment to sustaining your industrial control infrastructure with reliable,high-performance components.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

.jpg)