Description

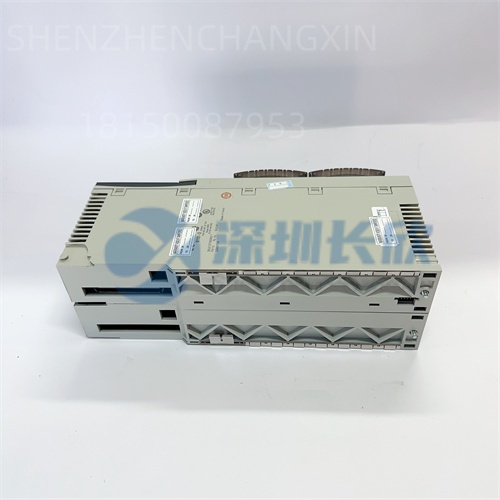

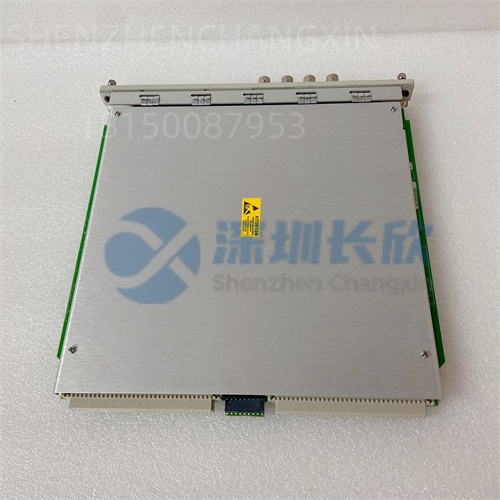

The ABB YPK112Ais a high-performance digital servo drive module manufactured by ABB,designed for precise motion control in industrial automation systems.This module acts as the intelligent power amplifier in a servo system,translating low-power command signals from a motion controller into the high-power current required to drive a servo motor with exceptional accuracy and dynamic response.It is engineered to deliver reliable,high-speed control for the most demanding positioning and velocity applications.

Application Scenarios

In a high-speed packaging line,a robotic pick-and-place unit must place products into moving cartons with millimeter precision at rates of over 100 cycles per minute.Any jitter,overshoot,or lag in the robot’s arm movement results in misplacements,product damage,and line stoppages.The ABB YPK112Aservo drive is the critical component that eliminates this problem.It receives a precise position command and,using real-time feedback from the motor’s encoder,continuously adjusts the power delivered to the servo motor.This ensures the arm moves with smooth,rapid,and exact trajectories,directly addressing the core pain points of production speed,product quality,and operational uptime in high-throughput automation.

Parameter

Main Parameters

Value/Description

Product Model

ABB YPK112A

Manufacturer

ABB Ltd.

Product Category

Digital Servo Drive/Amplifier

Output Current

15A RMS(Continuous)

Bus Voltage

600V DC(Typical,from 3-Phase input)

Control Modes

Torque,Velocity,Position(following±10V analog reference)

Feedback Type

Resolver,Encoder,Sin/Cos(dependent on firmware)

Communication Interface

DSQC(Drive-Side)&Feedback Interface

Switching Frequency

4-8 kHz(Typical for this class)

Protection Features

Overcurrent,Overvoltage,Overtemperature,Short Circuit

Operating Temperature

0°C to 45°C(with derating above 40°C)

Key Function

Precision control of 3-Phase AC Servo Motors

Technical Principles and Innovative Values

The ABB YPK112Autilizes advanced digital signal processing(DSP)and power electronics to achieve superior control performance.

Innovation Point 1:Advanced Control Algorithms.The ABB YPK112Aimplements sophisticated control loops,including PID with feedforward and notch filters.This allows it to precisely manage motor torque,cancel out mechanical resonances,and achieve extremely high bandwidth,resulting in smoother motion,reduced settling time,and higher accuracy compared to analog or simpler digital drives.

Innovation Point 2:Integrated Safety and Diagnostics.The drive features comprehensive hardware and software protection circuits that guard against overcurrent,overtemperature,and short circuits.Furthermore,its extensive diagnostic suite provides detailed fault records and system status,enabling predictive maintenance and drastically reducing mean-time-to-repair(MTTR)by quickly pinpointing the root cause of an issue.

Innovation Point 3:Seamless System Integration.Designed as part of ABB’s robotics and automation ecosystem,the ABB YPK112Ainterfaces natively with ABB’s motion controllers(like the ABB DSQC 346Robot Controller)and is optimized to drive ABB’s servo motors.This tight integration ensures optimal performance,simplifies commissioning,and provides a single-vendor solution for critical motion control tasks.

Application Cases and Industry Value

Case 1:Automotive Assembly Robot Retrofit

An automotive manufacturer was experiencing intermittent faults and”following error”alarms on a critical welding robot,causing the production line to halt several times a week.The existing servo drives could not keep up with the aggressive motion profiles.Replacing them with the ABB YPK112Adrives provided the necessary dynamic response and stability.The result was a complete elimination of motion-related faults,a 5%increase in cycle time due to the ability to run more aggressive trajectories,and a significant reduction in unplanned downtime,delivering a full return on investment in under six months.

Case 2:CNC Machine Tool Enhancement

A machine shop specializing in aerospace components needed to improve the surface finish and accuracy of a 5-axis milling machine.The existing drives caused slight vibrations during contouring operations.The installation of the ABB YPK112A,paired with high-resolution motors,provided exceptionally smooth torque control.This upgrade minimized vibration,improved surface finish quality by over 30%,and reduced geometric errors on complex parts,allowing the shop to take on higher-value contracts.

Related Product Combination Solutions

ABB YPK114A:A higher-power variant servo drive in the same series,offering a scalable solution for applications requiring more torque and speed.

ABB YB160103-AC/AD:A matched ABB synchronous servo motor,engineered to work optimally with the ABB YPK112Adrive for peak performance.

ABB DSQC 346:A main computer board for ABB robots,which acts as the motion controller,generating the trajectory commands for the ABB YPK112A.

ABB YPK101A:A power supply module for the drive system,providing the stable DC bus voltage required by the ABB YPK112A.

ABB YPK102A:A regulator module,often used in a multi-axis system to manage shared power resources and braking.

ABB 3HAC14557-1:A typical resolver feedback cable,providing the critical motor position data from the motor back to the ABB YPK112Adrive.

Installation,Maintenance,and Full-Cycle Support

Proper installation of the ABB YPK112Ais critical for reliable operation.The drive must be mounted on a properly rated,flat heatsink with the correct thermal interface material and torque specifications to ensure efficient heat dissipation.Power(3-phase AC)and motor connections must be made with shielded cables,and grounding must be implemented strictly according to EMC guidelines to prevent electrical noise from disrupting the sensitive control signals.

Routine maintenance involves periodic inspection for dust accumulation on heatsinks and checking terminal tightness during scheduled shutdowns.The drive’s diagnostic LEDs and fault history,accessible via its communication interface,are the first line of defense for troubleshooting.In the event of a fault,the detailed error codes allow for rapid identification of the issue,whether it’s related to the power supply,motor,or feedback system.Replacement is a structured process of power-down,disconnection,swap,and re-commissioning.

We provide comprehensive full-cycle support for the ABB YPK112A,from initial compatibility verification and system configuration to after-sales technical support.Our commitment includes providing genuine,factory-tested drives and access to firmware and documentation.Our global logistics network ensures you receive the critical components you need to minimize costly production downtime.

Contact us for a customized solution and to ensure optimal integration of the ABB YPK112Ainto your motion control system.

BENTLEY、TRICONEX、Woodward、FOXBORO、WESTINGHOUSE、Schneider、ABB、Motorola、GE、YOKOGAWA、HIMA、EMERSON