![]()

Product Overview

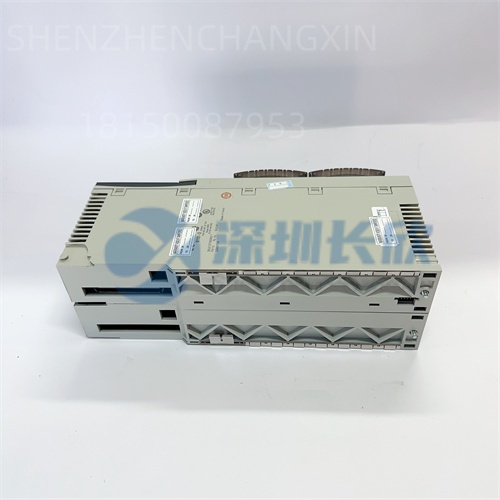

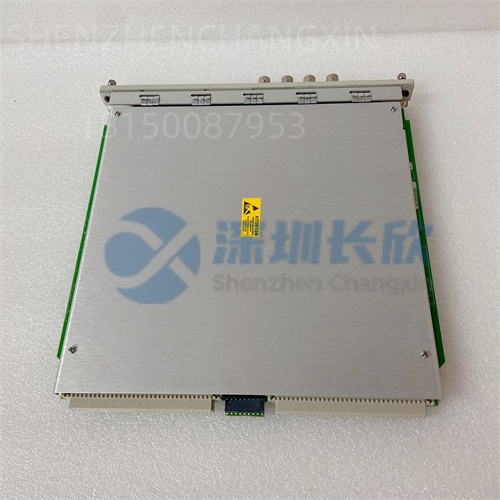

TRICONEX HCU3700/3703Eis a high-reliability triple modular redundant(TMR)safety controller manufactured by Triconex(now part of Schneider Electric)for critical process safety applications.This advanced safety system represents the pinnacle of safety instrumented system technology,designed to provide maximum availability and fault tolerance for the most demanding industrial applications.The TRICONEX HCU3700/3703Eimplements a sophisticated triple redundancy architecture where three independent control channels operate simultaneously,with continuous voting mechanisms that ensure safe operation even in the event of component failures.This design philosophy makes the TRICONEX HCU3700/3703Eparticularly suitable for applications where safety integrity and system availability are paramount concerns.

Engineered to meet the most stringent international safety standards,the TRICONEX HCU3700/3703Eachieves Safety Integrity Level(SIL)3 certification according to IEC 61508 and IEC 61511 standards,the highest safety classification for industrial control systems.The system’s robust architecture includes comprehensive diagnostics that continuously monitor the health of all components,providing early detection of potential failures and enabling predictive maintenance strategies.In hazardous process industries including oil and gas production,chemical processing,and power generation,the TRICONEX HCU3700/3703Eperforms critical safety functions including emergency shutdown(ESD),fire and gas detection(F&G),turbine control,and burner management systems.The controller’s modular design allows for flexible configuration while maintaining the highest levels of safety and reliability required for protecting human lives,environmental assets,and expensive equipment.

Technical Specifications

Parameter Name

Parameter Value

Product Model

TRICONEX HCU3700/3703E

Manufacturer

Triconex(Schneider Electric)

Product Type

TMR Safety Controller

Architecture

Triple Modular Redundant(TMR)

Safety Certification

SIL 3(IEC 61508/61511)

Processor

Three independent 32-bit processors

Memory Capacity

16MB user memory per channel

Scan Time

1-100ms programmable

I/O Capacity

Up to 15,000 points

Communication Ports

TriBus,Modbus TCP,Ethernet

Power Supply

100-240V AC,50/60Hz

Operating Temperature

0°C to 60°C

Storage Temperature

-40°C to 85°C

Relative Humidity

5%to 95%non-condensing

MTBF

>100 years

Fault Tolerance

Single fault tolerant

Diagnostic Coverage

>99.9%

Certifications

ATEX,IECEx,cULus

Main Features and Advantages

The TRICONEX HCU3700/3703Eincorporates advanced triple modular redundancy technology that ensures continuous operation even in the event of component failures.Each of the three independent channels processes identical logic simultaneously,with a sophisticated voting system that compares results and masks any single channel failure.This architecture provides exceptional fault tolerance while maintaining process availability.The system’s comprehensive online diagnostics continuously monitor hardware health,detecting more than 99.9%of dangerous failures.The TRICONEX HCU3700/3703Efeatures hot-swappable modules that can be replaced without system shutdown,significantly reducing maintenance downtime and improving overall system availability.

Integration and flexibility:The TRICONEX HCU3700/3703Esupports multiple communication protocols including TriBus for internal communication,Modbus TCP for SCADA integration,and Ethernet for engineering access.The controller’s flexible I/O system accommodates various signal types including discrete,analog,and specialty I/O modules.Advanced features include sequence of events(SOE)recording with 1ms resolution,which provides precise timestamping for troubleshooting and incident analysis.The system’s modular design allows for scalable configurations from small to very large safety applications,while maintaining the same high level of safety integrity throughout.

Triple modular redundancy for maximum availability

SIL 3 certification for safety-critical applications

Hot-swappable modules for online maintenance

Comprehensive diagnostic coverage>99.9%

Flexible communication and I/O options

Sequence of events with 1ms resolution

Application Field

The TRICONEX HCU3700/3703Efinds primary application in process industries where safety and availability are critical requirements.In oil and gas production facilities,the system performs emergency shutdown(ESD)functions for offshore platforms and onshore processing plants.The TRICONEX HCU3700/3703E’s fault-tolerant design ensures continuous operation even in remote locations where maintenance access is limited.In refinery applications,the controller manages critical safety functions including unit shutdowns,fire and gas detection,and pressure protection systems.

In chemical processing plants,the TRICONEX HCU3700/3703Eprovides safety interlocking for reactors,distillation columns,and storage facilities where process deviations could lead to hazardous situations.The system’s high availability ensures that production can continue safely while maintaining all safety functions.In power generation,particularly in turbine control applications,the TRICONEX HCU3700/3703Eprovides overspeed protection and emergency shutdown capabilities.The controller’s proven reliability makes it suitable for nuclear power plant safety systems where the highest levels of integrity are required.

Related Products

TRICONEX HCU3701:Enhanced version with increased processing power

TRICONEX 3008:Main processor module

TRICONEX 4351B:Analog input module

TRICONEX 3625:Thermocouple input module

TRICONEX 3805E:Digital input module

TRICONEX 3481:Power supply module

TRICONEX 4009:Communication module

TRICONEX 8312:Safety manager software

Installation and Maintenance

Installation requirements:The TRICONEX HCU3700/3703Erequires installation in a controlled environment with adequate ventilation and proper grounding.The system should be mounted in a secure cabinet with appropriate clearances for maintenance access.All field wiring must use appropriate cable types with proper separation between safety and non-safety circuits.Power supply connections should include appropriate overcurrent protection and surge suppression devices.

Maintenance recommendations:Regular maintenance includes verification of system diagnostics,checking of module status indicators,and review of system event logs.The TRICONEX HCU3700/3703E’s online diagnostic capabilities should be monitored continuously,with immediate attention to any detected faults.Periodic functional testing of safety functions should be performed according to the safety requirement specification.Firmware updates should be applied during planned maintenance windows following proper change management procedures.

Product Guarantee

We guarantee genuine TRICONEX HCU3700/3703Esafety controllers with full certification and traceability documentation.Each system undergoes comprehensive testing including processor synchronization,communication validation,and diagnostic function verification.Our quality assurance process ensures compliance with original manufacturer specifications and international safety standards.We provide complete technical documentation,safety manuals,and application support for proper system implementation.All products are backed by our comprehensive warranty and technical support commitment,with expedited replacement services available for critical safety applications.Our inventory management system maintains adequate stock levels to support both new projects and emergency requirements,ensuring continuous operation of your safety instrumented systems.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!