Description

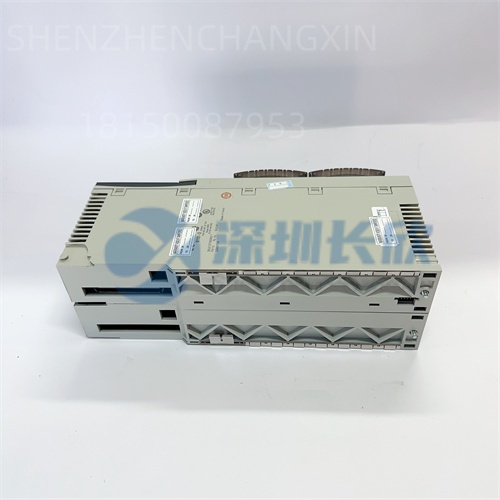

The HONEYWELL 05701-A-0301is a smart differential/gauge pressure transmitter manufactured by Honeywell Process Solutions.This precision instrument converts physical pressure into a standardized 4-20mA electrical signal with integrated HART communication,serving as the eyes of the control system for critical pressure and flow measurements in industrial processes.

Application Scenarios

In a large petrochemical refinery’s catalytic cracking unit,monitoring the differential pressure across catalyst bed filters is crucial for predicting clogging and scheduling maintenance before a costly shutdown occurs.The HONEYWELL 05701-A-0301is installed here,exposed to high temperatures and potentially corrosive process vapors.Its robust sensor and smart electronics don’t just transmit a raw milliamp signal;they continuously perform onboard diagnostics,validating sensor integrity.When the differential pressure trend begins to deviate from its normal profile,indicating filter fouling,the transmitter’s data,accessible remotely via its HART protocol,allows engineers to plan a maintenance turnaround weeks in advance.This predictive capability,enabled by the transmitter’s stability and smart features,transforms a critical measurement point from a simple monitor into a strategic asset for operational planning and risk mitigation,preventing unplanned outages that could cost millions in lost production.

Parameter

Main Parameters

Value/Description

Product Model

HONEYWELL 05701-A-0301

Manufacturer

Honeywell

Product Category

Smart Pressure Transmitter(Differential/Gauge)

Pressure Range

Specific range defined by suffix(e.g.,0-30 inH2O,0-500 psi).The-0301indicates a calibrated range.

Output Signal

4-20 mA DC,two-wire,with superimposed HART®digital communication.

Power Supply

10.5 to 45 V DC(loop powered)

Accuracy

Typically±0.075%of calibrated span(includes linearity,hysteresis,and repeatability)

Sensor Technology

Advanced silicon piezoresistive sensor

Process Connection

1/4″NPT or 1/2″NPT female(dependent on model variant)

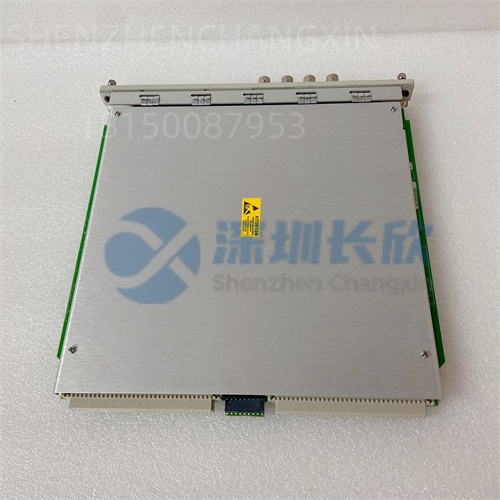

Electronics Housing

Aluminum or stainless steel with epoxy coating

Display

Optional local LCD indicator(likely not present on base-0301)

Environmental Rating

NEMA 4X(IP66/67)

Operating Temperature

-40°F to 185°F(-40°C to 85°C)for electronics;process temp depends on seal option.

Certifications

FM,FMc,CSA,ATEX,IECEx(for hazardous locations)

Technical Principles and Innovative Values

Innovation Point 1:Advanced Silicon Sensor with Laser Trimmed Compensation.The core of the HONEYWELL 05701-A-0301is a micromachined silicon sensor.Its resistance changes precisely with applied pressure.What sets it apart is the factory laser trimming of onboard resistors.This process digitally calibrates and compensates the sensor for offset,span,and,critically,temperature effects across its entire operating range.This yields exceptional long-term stability and accuracy right out of the box,minimizing the need for frequent field recalibration.

Innovation Point 2:Integrated Digital Intelligence in a Loop-Powered Device.Despite being powered solely by the modest 4-20mA loop(10.5-45V DC),the transmitter packs a powerful microprocessor.This brain enables the HART protocol,allowing bidirectional communication for configuration,diagnostics,and multivariable data access(like pressure and sensor temperature)without interrupting the analog signal.It turns a simple signal converter into a network-connected device that can report its health and re-range itself remotely.

Innovation Point 3:Robust Design for Hostile Environments.The 05701-A-0301is engineered for survivability.Its housing meets NEMA 4X standards,resisting hose-downs and corrosive atmospheres.The sensor can be isolated from hot or corrosive media using remote seals filled with inert fluids.This combination of electronic sophistication and mechanical toughness ensures reliable performance in the most challenging plant environments,from offshore platforms to chemical processing units.

Application Cases and Industry Value

Case Study:Power Plant Boiler Feedwater Flow Control.A combined-cycle power plant needed to optimize the efficiency of its high-pressure boiler feedwater pumps.Accurate flow measurement,derived from the differential pressure across orifice plates,was critical.They installed HONEYWELL 05701-A-0301transmitters on these lines.The transmitters’high accuracy(±0.075%)provided the precise data needed for the advanced control system to minimize pump recirculation and reduce parasitic energy consumption.Furthermore,during a scheduled outage,engineers used HART communicators to quickly verify the calibration of all transmitters without removing them from the line,saving days of labor.The plant manager reported a measurable improvement in heat rate efficiency and estimated a reduction in annual maintenance man-hours for instrumentation by 15%,attributing much of this to the reliability and diagnostic accessibility of the Honeywell transmitters.

Related Product Combination Solutions

HONEYWELL Experion PKS DCS:The overarching control system that receives,logs,and acts upon the measurement data from the 05701-A-0301,integrating it into plant-wide control and optimization strategies.

HONEYWELL STT35 Temperature Transmitter:Often installed in the same process line to provide complementary temperature compensation or monitoring,creating a complete process variable dataset.

HONEYWELL HC900 Hybrid Controller:A smaller control solution that can directly utilize the signal from the 05701-A-0301for localized loop control in skid-mounted equipment.

HONEYWELL Remote Diaphragm Seals(e.g.,Models with SST or Hastelloy diaphragms):Essential accessories that protect the 05701-A-0301’s sensor from clogging,corrosion,or extreme temperatures by isolating it with a chemically compatible fill fluid.

HONEYWELL HART Communicator(Fieldcomm GR-475):The handheld device used to configure,calibrate,and diagnose the 05701-A-0301in the field,accessing all its smart features.

HONEYWELL Pressure Manifolds(3-Valve or 5-Valve):Used to isolate,equalize,and vent the pressure connections to the 05701-A-0301for safe calibration and maintenance without process shutdown.

HONEYWELL MCT Series Compact Transmitters:A more compact alternative for less demanding applications,whereas the 05701-A-0301is chosen for its high performance and robustness.

Installation,Maintenance,and Full-Cycle Support

Installation and Commissioning:Installing the HONEYWELL 05701-A-0301is straightforward.It mounts directly to a pressure manifold or process connection.The two-wire loop connection is simple:connect the positive terminal to the DC power supply and the negative terminal to the controller’s input,completing the loop.Commissioning is greatly accelerated by its smart features.Using a HART communicator,technicians can verify factory calibration,set the desired range(within limits),assign tags,and test the output without applying physical pressure,using the transmitter’s sophisticated”simulate”function.

Maintenance and Lifecycle Support:Routine maintenance primarily involves verifying the zero point under static conditions.The transmitter’s exceptional stability often extends calibration cycles to several years.Its comprehensive self-diagnostics monitor sensor health,memory integrity,and electronics status,providing early warnings of potential issues.Should service be required,the modular design allows for electronics replacement in the field without recalibrating the sensor module,drastically reducing downtime.We provide full lifecycle support for the HONEYWELL 05701-A-0301,including guaranteed genuine Honeywell products,detailed technical specifications,calibration support,and access to firmware updates.Our global logistics network ensures you have the right part when you need it.

Contact us for a tailored consultation on how the reliable HONEYWELL 05701-A-0301 pressure transmitter can enhance the accuracy,reliability,and intelligence of your process measurements.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!