Description

Description

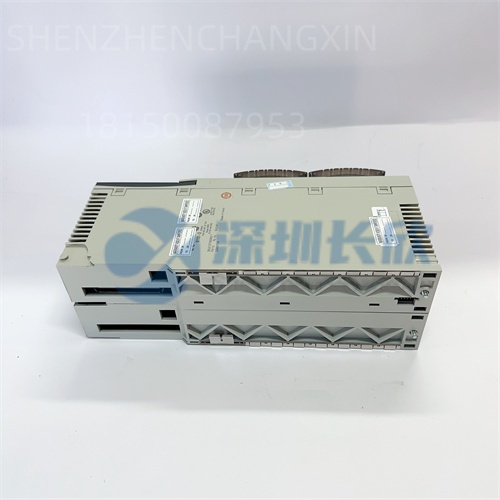

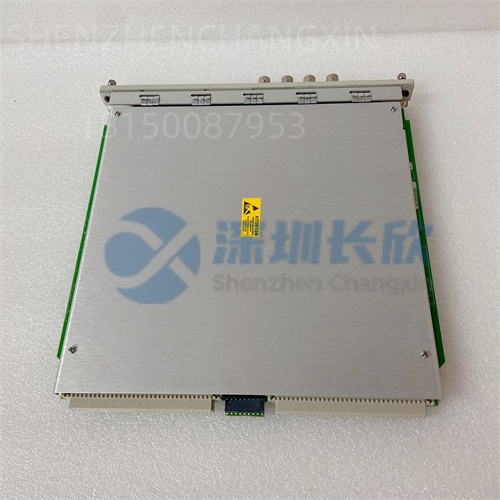

The LENZE EPZ-10203 is a compact,programmable safety controller from Lenze’s EPZ Safe PLC family,engineered to replace conventional safety relays in modern machinery while delivering full compliance with SIL 3(IEC 62061)and Performance Level e(EN ISO 13849-1).Designed for integration into automated production lines,the EPZ-10203 combines onboard safety-rated digital inputs and outputs with flexible communication interfaces,enabling intelligent,diagnostics-rich safety logic for motors,drives,and robotic cells.

Unlike fixed-function relays,the EPZ-10203 supports graphical programming via Lenze’s SafePLC Engineering Tool,allowing machine builders to implement complex safety functions—such as safe torque off(STO),safe stop,and muting sequences—with minimal wiring and maximum adaptability.

Application Scenarios

At a high-speed beverage bottling facility in Germany,a legacy safety relay panel caused repeated line stoppages due to undetected wiring faults in light curtain feedback loops.The OEM replaced it with a LENZE EPZ-10203 safety controller linked directly to Lenze i550 inverters via PROFIsafe over PROFINET.Now,when a palletizer guard door opens,the EPZ-10203 not only cuts motor power via STO but also logs the event timestamp,operator ID(from HMI),and diagnostic code for the specific input channel.During a recent audit,this granular data proved that all safety responses occurred within 18 ms—well below the 100 ms requirement.Downtime dropped by 60%,and maintenance teams now resolve issues remotely using the controller’s web-based diagnostics interface.

Parameter

Main Parameters Value/Description

Product Model EPZ-10203

Manufacturer Lenze SE

Product Category Programmable Safety Controller(Safe PLC)

Safety Certification SIL 3(IEC 62061),PL e/Category 4(EN ISO 13849-1),TÜV Rheinland certified

Integrated I/O 8 safety inputs+4 safety outputs(transistor,24 V DC)

Expandable I/O Yes–up to 32 additional safety I/O via EPZ bus modules

Communication Interfaces 2×Ethernet(RJ45):1 for engineering,1 for PROFINET/PROFIsafe or EtherNet/IP CIP Safety

Programming Environment Lenze SafePLC Engineering Tool(based on CODESYS Safety)

Response Time<20 ms(typical for 16 I/O safety logic)

Mounting DIN rail(35 mm),IP20 protection

Operating Temperature 0°C to+55°C

Certifications CE,UL 61010-2-201,CSA C22.2 No.61010-2-201

Technical Principles and Innovative Values

Innovation Point 1:True Programmable Safety Logic

The EPZ-10203 executes certified safety programs written in FBD(Function Block Diagram)or LD(Ladder Diagram),enabling dynamic responses like conditional muting,zone control,or speed-dependent safety—impossible with electromechanical relays.

Innovation Point 2:Native Drive Integration via Safe Fieldbus

Through PROFIsafe or CIP Safety,the EPZ-10203 communicates directly with Lenze and third-party inverters to trigger Safe Torque Off(STO),Safe Stop 1(SS1),or Safely Limited Speed(SLS)without extra wiring—reducing cabinet space and commissioning time.

Innovation Point 3:Embedded Web Server for Remote Diagnostics

Technicians access real-time status,fault logs,and I/O states via any browser—no software needed.This feature slashes mean time to repair(MTTR)in distributed production environments.

Innovation Point 4:Modular Scalability Without Compromise

While compact,the EPZ-10203 can expand to 32+safety I/O using plug-in EPZ modules(e.g.,EPZ-10211 for analog safety inputs),making it suitable for both small machines and large assembly lines—all under one safety program.

Application Cases and Industry Value

An automotive parts supplier in Mexico integrated the LENZE EPZ-10203 into a new robotic welding cell featuring dual-arm robots and servo-driven positioners.The safety logic included perimeter guarding,emergency stops,and safe speed monitoring during manual teaching mode.Thanks to the EPZ-10203’s ability to validate safe robot kinematics via encoder feedback over PROFIsafe,the cell achieved PL e without physical fencing in collaborative zones.OSHA inspectors approved the design,and the OEM reduced safety hardware costs by 35%compared to a relay-based approach.Over 18 months,zero safety-related incidents were recorded.

Related Product Combination Solutions

LENZE EPZ-10211:4-channel analog safety input module—extends EPZ-10203 for safe torque or temperature monitoring.

LENZE i550/i750 inverters:Support PROFIsafe—receive STO/SS1 commands directly from EPZ-10203.

LENZE EPM-10201:Power supply module—provides redundant 24 V for EPZ-10203 safety circuits.

LENZE SafePLC Engineering Tool:Official programming suite—enables drag-and-drop safety function blocks for EPZ-10203.

LENZE EPZ-10221:8-channel safety output relay module—for high-current contactor control beyond transistor limits.

Siemens ET 200SP F-DQ:Third-party PROFIsafe output—interoperable with EPZ-10203 in mixed-vendor lines.

Rockwell GuardLogix:Alternative architecture—but EPZ-10203 offers lower cost and Lenze drive synergy.

Pilz PNOZmulti:Competitor safety controller—yet EPZ-10203 provides deeper integration with Lenze motion systems.

Installation,Maintenance,and Full-Cycle Support

Installing the LENZE EPZ-10203 begins with DIN-rail mounting in the control cabinet,followed by connecting safety devices(e.g.,emergency stops,light curtains)to its screw terminals.The Ethernet port links to the plant network for configuration and monitoring.Using the SafePLC Engineering Tool,engineers import pre-certified safety function blocks,assign I/O tags,and download the program—all validated by Lenze’s built-in compiler for IEC 61508 compliance.

Maintenance is streamlined through the onboard web server:simply enter the IP address to view live I/O status,error history,and safety program execution flow.Failed modules are hot-replaceable in non-redundant setups,and firmware updates can be deployed remotely.All safety logic remains intact during power cycles thanks to non-volatile memory.

As a certified Lenze partner,we supply only genuine EPZ-10203 units with full factory traceability,pre-loaded firmware,and validation test reports.Each module undergoes functional safety verification before shipment.We offer technical onboarding,programming templates for common applications(e.g.,palletizers,conveyors,presses),and lifecycle management to support your machinery for 10+years.

Contact us for a customized solution—whether you’re an OEM designing next-gen equipment,a system integrator upgrading legacy safety panels,or a plant engineer seeking reliable spares with expert backup.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!