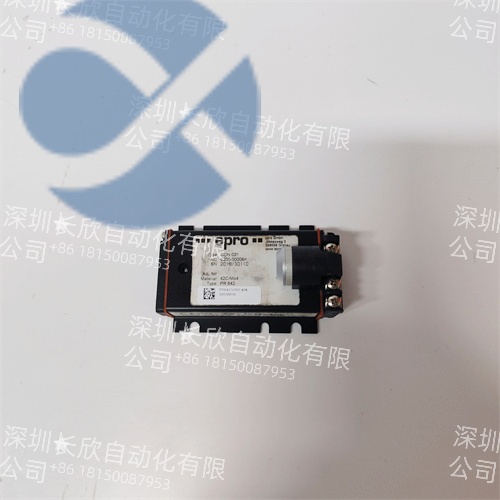

Description

EMERSON PR6423/000-131is a high-performance eddy current sensor manufactured by Emerson Process Management,designed for industrial automation applications.This industrial-grade sensor provides accurate measurement of process variables such as temperature,pressure,and flow rate,converting mechanical signals into standardized 4-20mA output for seamless integration with distributed control systems(DCS)and programmable logic controllers(PLC).With its robust construction and advanced sensing technology,the PR6423/000-131ensures reliable operation in demanding industrial environments,making it ideal for critical process monitoring and control applications across various industries.

Application Scenarios

In a large petrochemical facility,the EMERSON PR6423/000-131eddy current sensor plays a crucial role in monitoring critical rotating equipment such as centrifugal compressors and pumps.These sensors are installed on compressor bearings to measure shaft vibration and position,providing early warning of potential mechanical failures.During a recent maintenance cycle,the PR6423/000-131detected abnormal vibration patterns indicating bearing wear,allowing operators to schedule a controlled shutdown before catastrophic failure occurred.This early detection prevented an estimated$1.2 million in repair costs and avoided 48 hours of unplanned downtime,demonstrating the sensor’s value in maintaining production continuity and equipment reliability in high-value industrial processes.

Parameter

Main Parameters

Value/Description

Product Model

PR6423/000-131

Manufacturer

EMERSON

Product Category

Eddy Current Sensor

Supply Voltage

24V DC

Output Signal

4-20mA

Measurement Range

0-200μm(0-8 mils)

Frequency Response

10Hz to 1kHz

Linearity

±1%full scale

Operating Temperature

-40°C to+85°C

Protection Rating

IP67

Cable Length

8 m

Connection Type

Open end

Certification

CE,ATEX(optional)

Technical Principles and Innovative Values

The EMERSON PR6423/000-131utilizes advanced eddy current sensing technology to provide non-contact measurement of shaft vibration and position with micron-level accuracy.This technology operates on the principle of electromagnetic induction,where an alternating current in the sensor coil generates an electromagnetic field that induces eddy currents in the target surface.Changes in the target’s position alter the eddy current pattern,which in turn affects the sensor’s impedance,allowing precise measurement of distance and vibration.

Innovation Point 1:The PR6423/000-131features built-in temperature compensation that maintains measurement accuracy across the entire operating temperature range(-40°C to+85°C),ensuring reliable performance in extreme environments where conventional sensors would experience significant drift.

Innovation Point 2:The sensor’s IP67-rated stainless steel housing provides complete protection against water,oil,and dust ingress,making it suitable for installation in harsh industrial environments such as offshore platforms,petrochemical plants,and mining operations where exposure to corrosive elements is common.

Innovation Point 3:The EMERSON PR6423/000-131incorporates advanced signal conditioning circuitry that converts the raw analog signal into a standardized 4-20mA output,eliminating the need for external signal conditioners and reducing system complexity.This integrated approach enhances signal integrity and reduces installation costs.

Innovation Point 4:The sensor’s wide frequency response range(10Hz to 1kHz)enables it to capture both low-frequency vibration components associated with imbalance and misalignment,as well as high-frequency components indicative of bearing defects and gear mesh issues,providing comprehensive machinery health monitoring capabilities.

Application Cases and Industry Value

In a major power generation facility,the EMERSON PR6423/000-131eddy current sensors were deployed across multiple steam turbine generator sets to monitor critical shaft vibration and position parameters.The facility had been experiencing unplanned shutdowns due to bearing failures that were not detected early enough by the existing monitoring system.After installing the PR6423/000-131sensors,the plant’s maintenance team gained access to high-resolution vibration data that enabled them to implement a predictive maintenance strategy based on vibration trend analysis.

The results were significant:the facility achieved a 60%reduction in unplanned downtime related to rotating equipment failures and extended maintenance intervals by 40%.The plant’s maintenance manager reported:”The EMERSON PR6423/000-131sensors have transformed our approach to machinery health monitoring.We now have the data to make informed decisions about when to schedule maintenance,rather than waiting for alarms or failures.The high accuracy and reliability of these sensors have given us confidence in our predictive maintenance program.”

In another case,a chemical processing plant implemented the PR6423/000-131sensors on their critical reactor agitators.The sensors provided continuous monitoring of shaft vibration and position,enabling the plant to detect early signs of mechanical degradation and schedule maintenance during planned shutdowns.This proactive approach resulted in a 35%reduction in maintenance costs and improved overall equipment reliability.

Related Product Combination Solutions

EMERSON PR6423/000-131works seamlessly with several complementary products to create comprehensive machinery protection solutions:

EMERSON CSI9420 Vibration Monitor:A dual-channel monitor that accepts signals from the PR6423/000-131and provides relay outputs for alarm and shutdown functions,creating a complete machinery protection system.

EMERSON AMS 6500 Machinery Health Monitor:A comprehensive system that integrates vibration data from multiple PR6423/000-131sensors for advanced diagnostic capabilities and predictive maintenance strategies.

EMERSON DeltaV DCS System:The PR6423/000-131integrates directly with Emerson’s DeltaV distributed control system for centralized monitoring and control of process variables and equipment health.

EMERSON ProLink Plus Software:Configuration software for setting up and calibrating the PR6423/000-131sensors,enabling easy commissioning and maintenance.

EMERSON CSI 6500 Series Accelerometers:Complementary sensors for measuring casing vibration alongside shaft vibration from the PR6423/000-131,providing comprehensive machinery health monitoring.

EMERSON CSI 4500 Bearing Temperature Sensors:Temperature monitoring sensors that provide additional protection layers when used with the PR6423/000-131,creating a multi-parameter protection system.

EMERSON 5X00226G02 I/O Interface Module:An I/O interface module that can be used in combination with the PR6423/000-131to expand the I/O capabilities of the overall system,allowing for more comprehensive control of production processes.

AMS Suite:Intelligent Device Manager:Emerson’s device management software that enables remote monitoring,calibration,and diagnostic analysis of the PR6423/000-131and associated field devices,facilitating proactive maintenance and reducing unplanned downtime.

Installation,Maintenance,and Full-Cycle Support

Installing the EMERSON PR6423/000-131eddy current sensor requires proper mounting on the equipment bearing housing with the probe tip positioned at the recommended gap distance(typically 1.0-1.5mm from the shaft surface).The sensor should be mounted securely to prevent vibration-induced measurement errors,and the signal cable must be routed away from high-voltage power lines to minimize electromagnetic interference.The 4-20mA output signal should be connected to the DCS or PLC system using shielded twisted-pair cable with the shield grounded at one end only.

Routine maintenance of the PR6423/000-131involves periodic verification of the gap setting and checking for any physical damage to the probe or cable.The sensor’s IP67 rating ensures reliable operation in harsh environments,but regular inspection for signs of corrosion or cable damage is recommended.Calibration should be performed annually using a vibration simulator to verify measurement accuracy.The PR6423/000-131is designed for long service life with minimal maintenance requirements,typically exceeding 10 years in continuous operation.

Our company provides comprehensive technical support for the EMERSON PR6423/000-131,including installation guidance,commissioning assistance,and troubleshooting support.All products come with a 12-month warranty and are backed by our global supply chain network that ensures rapid delivery of replacement units when needed.We maintain extensive inventory of the PR6423/000-131and related accessories to minimize downtime for our customers.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!