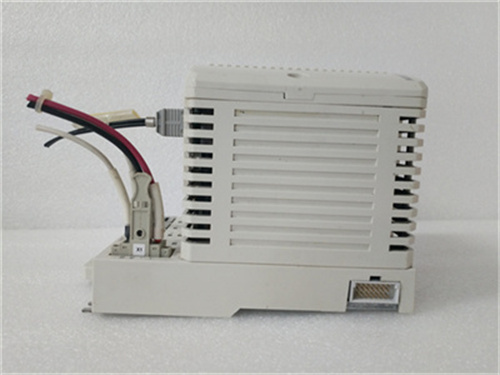

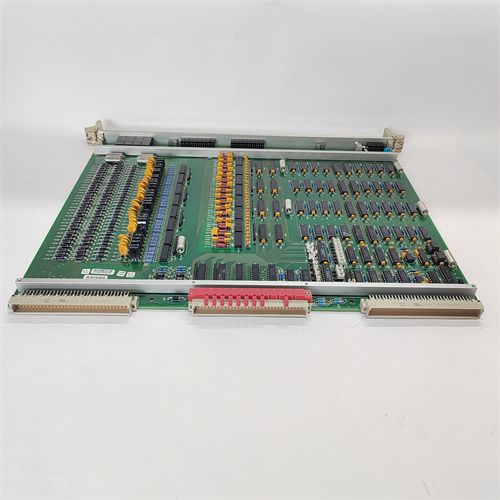

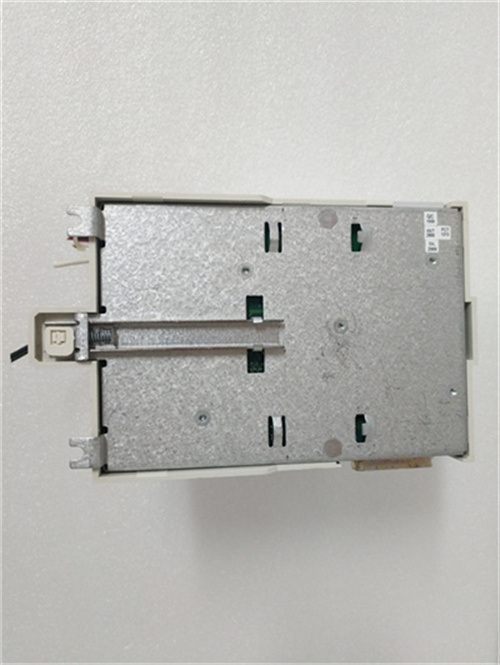

Application Scenarios:High-Speed Process Integration in LNGConsider a new Liquefied Natural Gas(LNG)facility where the primary compression train requires precise anti-surge control,load sharing,and rapid sequence execution.The margin for error is minimal,as any control instability can lead to catastrophic equipment failure or significant product loss.The traditional approach might use separate PLC and DCS systems,complicating data exchange and control logic.The ABB PM865K01 solves this complexity by providing a unified,high-speed control platform.Installed within the main compressor control panel,the PM865K01 executes the critical control applications,including advanced loop tuning and high-speed safety interlocks.Its ability to handle large I/O counts and rapidly process complex algorithms ensures the anti-surge control operates instantaneously,maintaining the compressor within its safe operating envelope.Furthermore,the PM865K01 natively integrates with the broader System$800text{xA}$operator interface,providing a single,consistent view of control and asset health,eliminating the need for complex gateways and drastically simplifying the control architecture for the facility’s operators and engineers.The robust design of the PM865K01 makes it the ideal choice for continuous,high-value process environments.Main ParametersParameterValue/DescriptionAnnotationProduct ModelPM865K01(3BSE031151R1)Controller Kit,including PM865 CPU and TP830 Baseplate.ManufacturerABBGlobal Leader in Process Automation(System 800xA).Product CategoryModular Process Controller(CPU)Core processing unit of the AC 800M series.Processor TypeHigh-Performance MIPS-based CPUOptimized for robust,real-time control execution.Program Memory$64text{MB}$($16text{MB}$Non-Volatile)High capacity for complex applications and history logging.Communication Ports$2timestext{Ethernet Ports}$(RJ45)For Controller-to-Controller/System$800text{xA}$communication.I/O ConnectivityCEX-Bus(via TP830)High-speed link to Communication Interface Modules(CI8xx).RedundancyYes(Dedicated Interface)Supports full hardware redundancy with a second PM865K01 unit.Programming StandardIEC 61131-3 CompliantSupports Function Block Diagram,Structured Text,etc.Operating Temperature$0text{°C}$to$55text{°C}$Designed for typical industrial control room environments.System IntegrationABB System$800text{xA}$Core controller module for the Extended Automation system.Installation MethodDIN Rail Mounting(via Baseplate)Standardized mounting for industrial control cabinets.Technical Principles and Innovative ValuesThe ABB PM865K01 is engineered based on the scalable and integrated principles of the AC 800M architecture,delivering distinct competitive advantages:Innovation Point 1:True Modular Redundancy(Active/Active Ready):The PM865K01 is redundancy-ready,allowing a second controller module and baseplate to be installed for synchronized,bumpless switchover.This high-availability feature ensures near-zero downtime,crucial for safety-critical and high-value continuous processes.Innovation Point 2:Native System 800xA Integration:Unlike controllers requiring complex OPC servers or gateways,the PM865K01 communicates natively using the$800text{xA}$connectivity protocol.This results in a unified data structure,simplified engineering,and faster data access for operator displays and asset management tools.Innovation Point 3:High Capacity and Performance:With$64text{MB}$of program memory and high-speed processing power,the PM865K01 can manage thousands of I/O points and execute complex control loops(including$text{PID}$,ratio control,and advanced algorithms)with extremely low execution times,improving control loop stability and product quality.Innovation Point 4:Flexible I/O and Communication Expansion:The use of the CEX-Bus on the baseplate allows the PM865K01 to connect to various Communication Interface Modules(CI854A for Profibus,CI858 for Modbus)and integrate diverse remote I/O families,including ABB’s own S800 I/O and S900 I/O.Application Cases and Industry ValueCase Study:Pulp and Paper Mill Control UpgradeA large pulp and paper manufacturing facility faced aging control hardware(e.g.,ABB Advant Controllers)that was increasingly difficult to maintain.They embarked on a migration to the System$800text{xA}$platform,utilizing the ABB PM865K01 as the new standard for the pulp drying and chemical recovery areas.Application Process:The control logic was transferred to the PM865K01 units,and the controllers were installed in the existing field cabinets,connected to new S800 I/O via fiber optic communication links.The controllers were deployed in redundant pair configurations to manage the steam generation and chemical injection systems.Improvements and User Feedback:Following the upgrade,the mill reported a$15%$improvement in control loop performance in the steam header,which directly reduced steam consumption variability.Engineers appreciated the PM865K01’s enhanced diagnostic capabilities,which provided granular detail on I/O health and communication status,leading to a$40%$reduction in time spent troubleshooting field faults.The simplified,high-speed integration between the PM865K01 and the$800text{xA}$asset management system ensured predictive maintenance was possible,significantly reducing the risk of unplanned shutdowns.Related Product Combination SolutionsThe ABB PM865K01 forms the control center and integrates with a wide array of ABB hardware to form a complete$800text{xA}$system:PM866K01:A higher-performance AC 800M controller kit,offering increased processing speed and memory capacity for the most demanding applications.TP830:The dedicated baseplate for the PM865K01,essential for providing power,CEX-Bus communication,and mounting.TC810:The specialized CEX-Bus cable used to connect the PM865K01 to the Communication Interface(CI)modules or adjacent controllers in redundant configurations.CI854A:A crucial Communication Interface Module that connects the AC 800M system to third-party devices via the widely used PROFIBUS-DP protocol.AI810(Analog Input Module):A standard S800 I/O module used to acquire$4-20text{mA}$process signals,which reports directly to the PM865K01 via a CI module.DO810(Digital Output Module):A standard S800 I/O module used by the PM865K01 to actuate control elements like valves and motor contactors.PM865A:The latest,enhanced version of the PM865 controller,offering improved performance and support for modern operating systems,serving as the direct upgrade path.Installation,Maintenance,and Full-Cycle SupportThe design of the ABB PM865K01 prioritizes straightforward installation and maximum uptime.The PM865K01 CPU unit slides easily into the TP830 baseplate,which is quickly mounted on a standard$35text{mm}$DIN rail.The entire process requires minimal specialized tooling.Once installed,the module’s modularity facilitates maintenance.The PM865K01 supports hot-swapping—a key feature where the CPU unit can be replaced without powering down the entire control system or disrupting control on a redundant partner,drastically reducing maintenance windows.Environmental adaptability is assured,with the PM865K01 designed to withstand industrial temperatures and electrical interference.For ongoing reliability,the controller features robust self-diagnostics,constantly monitoring its health,memory integrity,and communication links.Faults are immediately reported to the$800text{xA}$system,allowing proactive intervention.We provide comprehensive full-cycle support for the PM865K01,offering expert technical assistance,configuration backup management,and guaranteed supply of tested spare units to ensure the longevity and sustained high performance of your critical ABB System$800text{xA}$infrastructure.Contact us for a customized solution and inventory management plan tailored to your ABB System 800xA control platform.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!