Product Description

The YOKOGAWA YNT511Dis a high-performance,4-wire Intelligent Temperature Transmitter from Yokogawa’s YTA series,designed for use with resistance temperature detectors(RTDs)such as Pt100,Pt1000,and Ni1000.It accurately converts the small resistance change of an RTD into a stable 4-20mA analog signal with superimposed HART digital communication.Engineered for reliability and precision,it is a cornerstone for temperature measurement in demanding process industries like oil&gas,chemical,and power generation.

Application Scenario

In a high-pressure steam reformer at an ammonia plant,monitoring catalyst bed temperature is critical for yield optimization and to prevent thermal runaway.A 4-wire Pt100 RTD,installed in a thermowell,is connected to a YOKOGAWA YNT511Dtransmitter.The transmitter’s 4-wire measurement technique uses separate pairs for current excitation and voltage sensing,eliminating the effect of lead wire resistance and ensuring laboratory-grade accuracy from the control room,hundreds of meters away.During a process upset,a temperature spike occurred.The YNT511D,with its fast update rate and advanced filtering,provided a stable,real-time signal to the safety system.Concurrently,its onboard diagnostics detected a subtle,long-term drift in the sensor’s resistance characteristic,suggesting potential moisture ingress or sensor aging.It sent a”Predictive Maintenance”alert via HART.During the next planned turnaround,the RTD was inspected and found to be degrading.Replacing it proactively prevented an undetected failure that could have led to inaccurate control or a missed safety trip.This scenario demonstrates the transmitter’s dual value:delivering the exact,high-integrity data needed for both control and safety,while acting as an early warning system for the sensor itself,ensuring the entire measurement loop’s long-term reliability.

Key Parameters

Main Parameters

Value/Description

Product Model

YOKOGAWA YNT511D

Manufacturer

Yokogawa Electric Corporation

Product Category

Intelligent Temperature Transmitter(RTD Input)

Input Sensor

2/3/4-wire RTDs:Pt100,Pt1000,Ni1000(JIS,IEC,DIN)

Measurement Principle

4-wire resistance measurement for highest accuracy.

Output Signal

4-20 mA DC,two-wire,with HART 5/7/8 protocol.

Accuracy

±0.1%of span or better(including RTD conformity error).

Long-Term Stability

Excellent,typically<±0.1%of URL per 5 years.

Ambient Temperature Effect

Minimal,typically<±0.015%of URL per 10°C.

Diagnostics

Sensor break,short,degradation;configuration error;process variable out of range.

Safety Certification

SIL 2 capable(with appropriate safety manual and design).

Enclosure

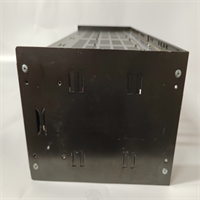

Robust,field-mountable housing with IP66/IP67 rating.

Technical Principles and Innovative Values

True 4-Wire Measurement for Ultimate Accuracy:The YNT511D’s core advantage is its use of a 4-wire(Kelvin)resistance measurement circuit.It drives a precise,constant current through the RTD using two wires and measures the voltage drop directly across the RTD’s terminals with a separate pair of wires.Because the voltage sensing circuit has extremely high input impedance,the current flowing in the sense wires is negligible.This means the resistance(and thus voltage drop)of the lead wires is not included in the measurement,completely eliminating error from lead wire resistance.This is critical for long cable runs and for achieving the highest possible system accuracy(often 0.1%or better).

Advanced Sensor Diagnostics and”Heartbeat”Monitoring:Beyond basic break/short detection,the transmitter performs sophisticated analysis of the RTD’s behavior.It can track the sensor’s historical resistance values and identify gradual changes that indicate aging,coating,or moisture ingress.Some advanced diagnostics can even identify a drifting or failing sensor by analyzing its response compared to expected physical models.This transforms the transmitter from a simple converter into a predictive asset management tool,enabling maintenance before measurement integrity is compromised.

Exceptional Stability and Noise Immunity:The transmitter is designed for long-term stability in harsh environments.Its analog front-end and A/D converter are optimized for low drift.It employs advanced digital filtering algorithms that effectively reject electrical noise common in industrial plants(from motors,VFDs,radio transmitters)without introducing significant lag in the measured value.This combination provides a clean,stable signal that is essential for precise temperature control loops and reliable safety system inputs.

Application Cases and Industry Value

Case Study:LNG Liquefaction Train Cold Box Monitoring

In a liquefied natural gas(LNG)plant,the”cold box”contains a complex heat exchanger operating at cryogenic temperatures.Monitoring dozens of these temperatures with extreme accuracy is vital for process efficiency and detection of blockages.The plant used YOKOGAWA YNT511Dtransmitters with specialized cryogenic RTDs.The engineering lead explained:”The accuracy and stability of the YNT511Dtransmitters are non-negotiable at-160°C.Their 4-wire measurement eliminates any uncertainty from our long cable runs.We’ve correlated their readings with laboratory calibrations,and the drift is negligible over years.During a recent performance test,one transmitter’s diagnostics flagged an anomaly in a specific RTD.We were able to cross-check with neighboring sensors and confirm a developing issue in the heat exchanger passage,allowing for a targeted investigation during the next outage.The reliability of this temperature data is foundational to our advanced process control models,which have improved train efficiency by 0.7%.”This case highlights the transmitter’s value in the most demanding measurement applications,where its precision enables advanced optimization and its diagnostics contribute to predictive maintenance of the process itself,directly impacting multi-million dollar production efficiency.

Related Product Combination Solutions

The YOKOGAWA YNT511Dis the centerpiece of a high-integrity temperature measurement loop:

RTD Sensor(Pt100/Pt1000):The primary sensing element,often mounted in a thermowell for process insertion.Its accuracy class and installation directly impact the loop performance.

Thermowell:Protects the RTD from process pressure,flow,and corrosion.Its design affects response time,which the transmitter’s damping setting can help manage.

Field Barrier or Isolator(for IS applications):In intrinsically safe installations,a barrier is placed between the safe-area control system and the YNT511Din the hazardous area.

Control System(DCS/PLC):The host that receives the 4-20mA/HART signal,displays the temperature,executes control algorithms,and collects diagnostic alerts from the transmitter.

Asset Management Software(Yokogawa PRM,Emerson AMS):Used for remote configuration,calibration management,and monitoring the diagnostic health of all YNT511Dtransmitters plant-wide.

HART Communicator or Handheld Configurator:For local configuration,calibration,and diagnostics at the transmitter location in the field.

Installation,Maintenance,and Full-Cycle Support

Installation requires correct wiring:the 4 wires from the RTD must be connected to the correct terminals on the transmitter to enable the 4-wire measurement.The transmitter is typically mounted on a pipe or a rack near the process connection.Configuration is performed via the local buttons,a HART communicator,or asset management software,where the RTD type,temperature range,and damping are set.

Maintenance is driven by condition.The transmitter’s diagnostic alerts should be integrated into the plant’s work order system.Periodic verification of the loop accuracy can be done by simulating RTD resistance with a precision calibrator at the transmitter terminals.Our support provides genuine,factory-calibrated YOKOGAWA YNT511Dtransmitters.We assist in selecting the right model for your RTD type and safety requirements.We provide detailed manuals and guidance on achieving optimal accuracy through proper installation and configuration.We are committed to being your partner in achieving reliable,precise temperature measurement that supports both operational excellence and predictive maintenance strategies.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!