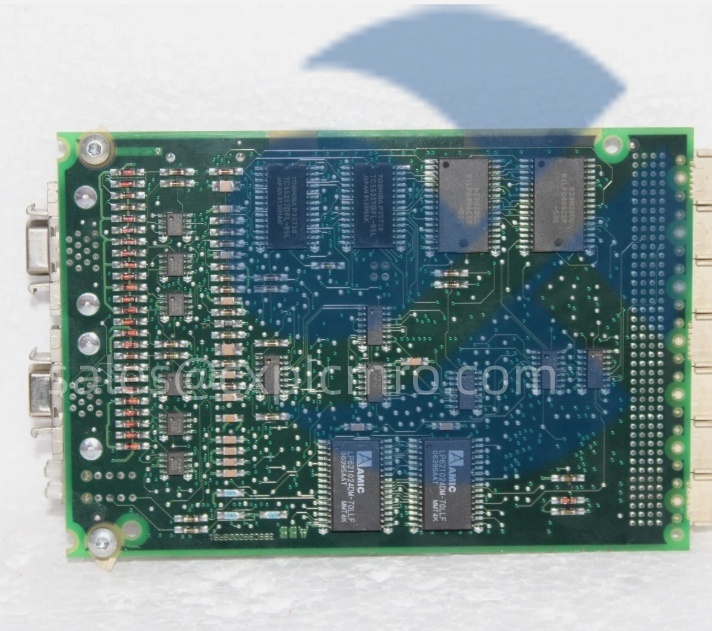

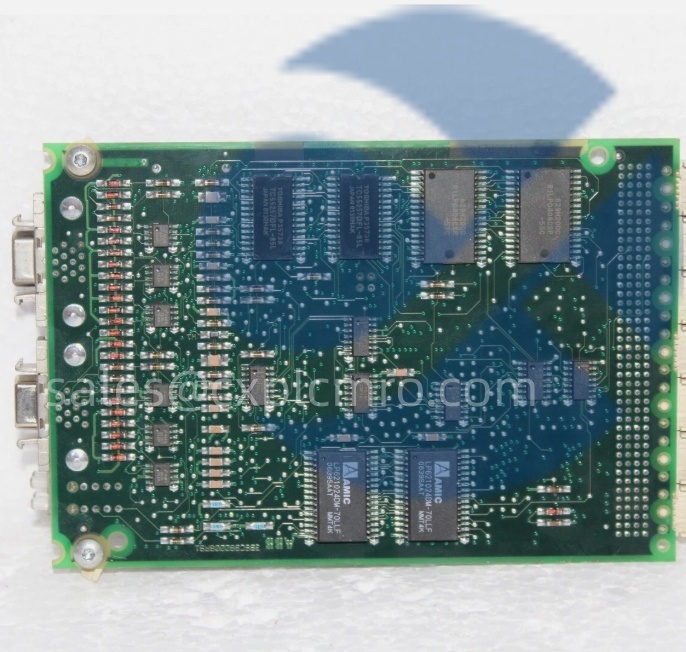

Description

The ABB CI535V30(Order Code:3BSE022162R1)is a high-performance PROFIBUS DP(Decentralized Periphery)communication module designed for the AC 800M programmable logic controller(PLC)platform within ABB’s System 800xA distributed control system(DCS).This module enables the AC 800M CPU to act as either a PROFIBUS DP Master(controlling remote I/O,drives,and valves)or a DP Slave(for peer-to-peer communication or integration into higher-level networks).With support for data rates up to 12 Mbps,connection to up to 126 slave devices per segment,and built-in redundancy synchronization,the CI535V30 is engineered for mission-critical process automation in industries such as oil&gas,power generation,chemicals,and mining.

Housed in a compact DIN-rail mountable form factor,the module features an isolated RS-485 PROFIBUS interface,status and diagnostic LEDs,and full compatibility with GSD(General Station Description)files for seamless integration of third-party devices(e.g.,Siemens ET 200,Pepperl+Fuchs remote I/O,ABB ACS880 drives).It supports hot-swap replacement in powered racks and integrates natively with ABB’s Control Builder M engineering tool for configuration,diagnostics,and online monitoring.

Application Scenarios

At a combined-cycle power plant in Germany,an AC 800M controller equipped with CI535V30 modules manages turbine auxiliary systems via PROFIBUS DP.One CI535V30 acts as Master,polling 45 remote I/O stations(ABB TB550-T)for valve positions and pump statuses.A second CI535V30 operates in redundant mode,synchronized with its partner in a standby CPU rack.During a scheduled maintenance window,a faulty field device caused repeated bus errors.Using Control Builder M,engineers isolated the issue to a specific slave address,then hot-swapped the CI535V30 module without interrupting turbine operation—demonstrating the system’s high availability and diagnostic depth.

Parameter

Main Parameters Value/Description

Product Model CI535V30

Order Code 3BSE022162R1

Manufacturer ABB Automation Products(now part of Hitachi Energy ecosystem,but still branded ABB)

Product Category PROFIBUS DP Communication Interface for AC 800M

Supported Roles PROFIBUS DP Master or DP Slave(configurable via software)

Data Rate 9.6 kbps to 12 Mbps(auto-baud or fixed)

Max.Slaves per Segment 126(with repeaters)

Max.I/O Data 244 bytes input+244 bytes output per slave

Electrical Interface Isolated RS-485,9-pin Sub-D(male),meets IEC 61158-2

Isolation Voltage 500 V RMS between backplane and field side

Redundancy Support Yes–synchronized operation in redundant AC 800M systems

Hot-Swap Yes–certified for live insertion/removal

Configuration Tool Control Builder M(part of System 800xA Engineering)

Diagnostics

Module status(RUN,STOP,ERROR)

Bus activity(TX/RX)

Slave-specific fault reporting

Online bus monitor in Control Builder M||Power Consumption|2.5 W(from AC 800M backplane)||Operating Temperature|0°C to+60°C||Certifications|CE,UL 61010,cULus,RoHS,ATEX(when installed in certified enclosures)||Dimensions|Standard AC 800M module:~230 mm H×35 mm W×depth fits 3-slot carrier|

Technical Principles and Innovative Values

Innovation Point 1:Dual-Mode Flexibility

Can be configured as Master(for controlling field devices)or Slave(for integrating AC 800M into another DCS)—maximizing architectural flexibility.

Innovation Point 2:Deep System 800xA Integration

Appears as a native I/O channel in Aspect Objects,enabling unified asset management,alarm handling,and historian logging.

Innovation Point 3:Advanced Diagnostics

Provides per-slave health status,bus load percentage,and error counters—critical for predictive maintenance in large installations.

Innovation Point 4:Future-Proof Migration Path

Enables reuse of existing PROFIBUS infrastructure while migrating to System 800xA,avoiding costly rip-and-replace projects.

Application Cases and Industry Value

Oil Refinery(USA):Uses CI535V30 to connect 80+ABB flow meters and motor starters over PROFIBUS—reducing wiring by 70%vs.hardwired I/O.

Water Treatment Plant(Sweden):Integrates Siemens S7-300 PLCs as slaves into an ABB DCS via CI535V30 in Slave mode,enabling centralized SCADA oversight.

Mining Conveyor System(Chile):Deploys redundant CI535V30 pairs to ensure uninterrupted communication to remote drive panels across 3 km of tunnel—achieving 99.99%uptime.

Related Product Combination Solutions

AC 800M CPUs:PM864,PM865(redundant),PM866

I/O Modules:AI810,AO810,DI810,DO810(local);TB510,TB550(remote PROFIBUS I/O)

Engineering Software:Control Builder M,System 800xA Composer

Network Infrastructure:ABB TB520 PROFIBUS repeater,Phoenix Contact FL SWITCH for segment isolation

Successor Technology:CI871/CI872(for PROFINET);however,CI535V30 remains in active production for brownfield support

GSD Files:Available from ABB Library or vendor-specific(e.g.,ABB_022162.gsd)

Installation,Maintenance,and Full-Cycle Support

Installation Best Practices:

Use shielded,twisted-pair PROFIBUS cable(e.g.,Belden 3076R)

Terminate both ends of each segment with 220Ωresistors

Ground shield at one point only to avoid ground loops

Assign unique station addresses(1–126)via DIP switches or software

Maintenance Guidance:

Monitor bus load in Control Builder M—keep below 60%for stability

Replace modules showing frequent sync loss or CRC errors

Keep firmware updated via ABB’s Update Manager

We supply brand-new,original ABB CI535V30(3BSE022162R1)modules with:

Factory warranty(typically 18 months)

Original ABB packaging and labels

Compliance documentation(CE,UL)

Our support includes:

Verification of compatibility with your AC 800M firmware version

Provision of correct GSD file for third-party device integration

Global shipping with ESD-safe packaging

Contact us for genuine ABB CI535V30 3BSE022162R1 PROFIBUS communication modules—whether you’re expanding a System 800xA DCS,modernizing a legacy plant,or maintaining critical process infrastructure,this robust,diagnostics-rich interface ensures reliable,high-speed connectivity between your AC 800M controller and the industrial field network.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!