Description:

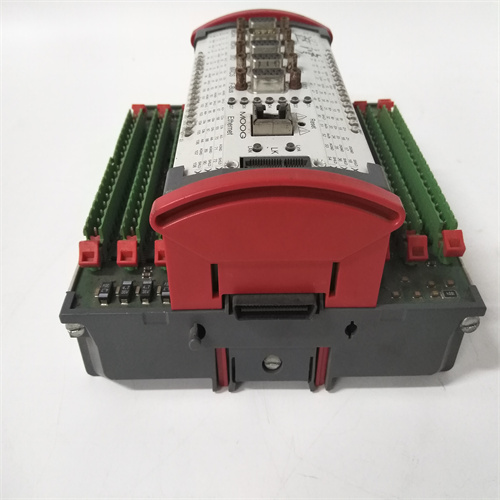

The MOOG D136-001-007 is a high-performance,two-stage electro-hydraulic servo valve designed for precise control of hydraulic actuators in demanding industrial,aerospace,and test applications.As part of Moog’s legendary D136 series—renowned for reliability,fast response,and long service life—this valve converts low-power electrical input signals(typically±10 V or 4–20 mA)into accurately modulated high-flow hydraulic output,enabling dynamic control of position,velocity,force,or pressure.

Engineered with jet-pipe first-stage technology and hardened spool materials,the D136-001-007 delivers exceptional contamination tolerance,stability under varying load conditions,and consistent performance even in harsh environments with high vibration,temperature extremes,or fluid degradation.

Application Scenarios:

At a heavy forging plant in Germany,a 10,000-ton hydraulic press suffered from inconsistent ram positioning during closed-die stamping,causing scrap rates to exceed 8%.The root cause was traced to an aging proportional valve with sluggish response and hysteresis.After installing the MOOG D136-001-007,closed-loop position accuracy improved to±0.05 mm,and cycle time decreased by 12%due to faster valve dynamics.Over 18 months,the plant reduced material waste by€1.2M annually and eliminated unscheduled downtime from valve clogging—thanks to the D136-001-007’s superior filtration compatibility and jet-pipe design that resists particle jamming.

Parameter:

Main Parameters Value/Description

Product Model D136-001-007

Manufacturer Moog Inc.

Product Category Two-Stage Electro-Hydraulic Servo Valve

Valve Type Jet-pipe pilot stage+spool main stage

Flow Rating(atΔP=70 bar)~7 liters/minute(1.85 GPM)

Supply Pressure Up to 210 bar(3,000 psi)

Input Signal±10 VDC(standard);optional 4–20 mA or LVDT feedback models

Frequency Response≥60 Hz(–90°phase lag,typical)

Hysteresis<1%of rated input

Linearity≤2%(best straight line)

Operating Temperature–20°C to+80°C(fluid temperature)

Fluid Compatibility Petroleum-based hydraulic oils(ISO VG 32–68),fire-resistant fluids(with seal options)

Mounting ISO 4401-03-02-0-05(CETOP 03/NG6)

Certifications CE,compliant with ISO 13766(earth-moving machinery EMC)

Note:The“007”suffix typically denotes standard configuration with steel body,Buna-N seals,and±10 V command signal.

Technical Principles and Innovative Values:

Jet-Pipe First Stage:Unlike flapper-nozzle designs,Moog’s jet-pipe technology offers higher contamination tolerance and lower sensitivity to fluid wear—ideal for industrial hydraulics where filtration may degrade over time.

High Dynamic Response:The lightweight pilot stage enables rapid spool movement,supporting bandwidths>60 Hz for real-time force/position control in presses,simulators,and flight controls.

Fail-Safe Options:While the base D136-001-007 is non-spring-centered,it can be integrated with external dump valves or used in redundant circuits for safe shutdown on power loss.

Modular Repairability:Moog provides field-serviceable kits(e.g.,D136-KT001)to replace coils,filters,or spools without removing the entire valve from the manifold—reducing MTTR by up to 70%.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!