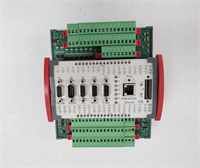

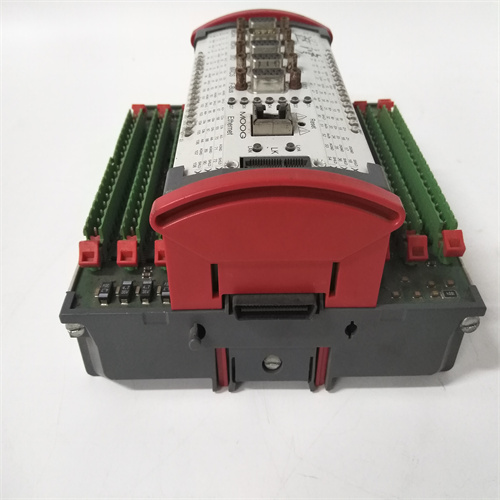

Description

The**MOOG G403-552A**is a high-response,three-stage electro-hydraulic servo valve engineered for demanding closed-loop motion control applications.As a core component in precision hydraulic systems,it converts low-power analog electrical signals(typically±10 VDC)into precisely modulated high-pressure fluid flow,enabling accurate control of cylinder position,force,or velocity.The**MOOG G403-552A**combines Moog’s legacy of aerospace-grade reliability with industrial ruggedness,making it a trusted solution in power generation,structural testing,and heavy machinery automation.

Application Scenarios

At a major aerospace test facility in Germany,engineers struggled with inconsistent results during fatigue testing of landing gear components due to hysteresis and drift in their aging servo valves.After upgrading to the**MOOG G403-552A**,they achieved repeatable actuator positioning within±0.02 mm over 10,000 cycles at 15 Hz—critical for validating airframe life predictions.The**MOOG G403-552A**’s hardened spool and proprietary jet-pipe pilot stage maintained performance despite occasional fluid contamination from system wear,eliminating unscheduled downtime for valve cleaning.This reliability translated into a 40%reduction in test cycle validation time and accelerated certification timelines for next-gen aircraft programs.

Parameter

Main Parameters|Value/Description—|—Product Model|**G403-552A**Manufacturer|Moog Inc.(Industrial Controls Division)Product Category|Three-Stage Electro-Hydraulic Servo Valve Control Signal|±10 VDC analog input(differential recommended)Flow Rating|55 gpm(208 L/min)atΔP=1000 psi(70 bar)across main spool Pressure Rating|Up to 3000 psi(210 bar)working pressure Frequency Response|≥80 Hz(–90°phase lag,no load)Hysteresis|<1.5%of rated flow(typical)Spool Type|Zero-lapped,hardened stainless steel with anti-wear coating Redundancy/Monitoring|Optional LVDT feedback for spool position;fault detection output Fluid Compatibility|Petroleum-based hydraulic fluids(ISO VG 32–68),filtered to NAS 1638 Class 6 Operating Temperature|–20°C to+80°C(fluid temperature)Certifications|CE,RoHS,compliant with ISO 4406 cleanliness standards

Technical Principles and Innovative Values

-**Innovation Point 1:Jet-Pipe Pilot Stage with Inherent Redundancy**–Unlike flapper-nozzle designs prone to clogging,the**MOOG G403-552A**uses a robust jet-pipe first stage that tolerates higher contamination levels while delivering stable null bias—ideal for industrial environments where perfect filtration isn’t guaranteed.-**Innovation Point 2:Three-Stage Force Amplification Architecture**–A low-power torque motor drives the jet-pipe pilot,which controls a second-stage amplifier spool,ultimately shifting the high-flow main spool.This cascade enables precise micro-motion control even at high system pressures—unachievable with two-stage valves.-**Innovation Point 3:Hardened Spool and Sleeve Technology**–Surface-treated mating components resist galling and wear,extending service life by up to 3×compared to standard servo valves in high-cycle applications like seismic simulators or rolling mills.-**Innovation Point 4:Integrated Diagnostics Capability**–Optional spool position feedback via built-in LVDT allows real-time health monitoring and predictive maintenance—detecting stiction or drift before it impacts process quality.

Application Cases and Industry Value

A hydroelectric dam in Brazil retrofitted its turbine wicket gate actuators with**MOOG G403-552A**valves to replace obsolete mechanical governors.During a grid frequency collapse event,the system responded within 200 ms to stabilize generator output—meeting ANEEL(Brazilian regulator)fast-response requirements.Over 18 months,zero valve-related failures occurred despite operating in high-humidity,dust-prone conditions near the spillway.Plant engineers reported a 30%reduction in maintenance labor and eliminated annual valve rebuilds,directly improving dispatch reliability and revenue under capacity market rules.

Related Product Combination Solutions

-**MOOG D662/D663 Series**:Two-stage direct drive valves for lower-flow applications(<20 gpm).-**MOOG G761-300x**:High-dynamic servo valve for flight control simulators requiring>100 Hz response.-**Bently Nevada 3500/25**:Vibration monitoring system that can trigger safety shutdowns if**G403-552A**actuator oscillations exceed limits.-**GE Mark VIe IS420ESVPH1A**:Provides the±10 VDC command signal to**G403-552A**in turbine control retrofits.-**Parker Hannifin PAVC Series**:Complementary pressure-compensated pump to maintain stable supply to**G403-552A**.-**Rexroth 4WRPE**:Electro-hydraulic proportional valve alternative for less dynamic—but cost-sensitive—applications.-**Moog MFB-403 Feedback Module**:External spool position transducer kit for legacy**G403-552A**units without built-in LVDT.-**HYDAC EDS 3400**:Pressure switch used to interlock**G403-552A**operation with system pressure status.

Installation,Maintenance,and Full-Cycle Support

Installing the**MOOG G403-552A**requires clean,dry hydraulic lines flushed to NAS 1638 Class 6 or better.Use thread sealant only on pipe threads—not face seals—and torque fittings per SAE AS4777 standards to avoid internal stress.Electrical connections should use shielded twisted-pair cable grounded at the controller end only to prevent ground loops.Always install a 10-micron(or finer)high-beta filter upstream,and consider a magnetic plug to capture ferrous wear debris.

Routine maintenance includes quarterly inspection of fluid cleanliness,checking for external leaks at mounting flanges,and verifying null bias current(typically 0–5 mA offset).If equipped with LVDT feedback,perform annual calibration against a known position reference.The MOOG G403-552A is not field-serviceable—should performance degrade beyond tolerance,return it to an authorized Moog service center for recalibration or replacement.

We supply only genuine,factory-new or Moog-certified refurbished G403-552A units,each accompanied by a performance test report including flow gain,hysteresis,and frequency response data.All valves are stored in climate-controlled conditions and packaged with desiccant to prevent internal corrosion.Backed by a 12-month warranty and access to Moog-trained application engineers,we ensure your hydraulic motion system delivers precision,day after day.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!