Description

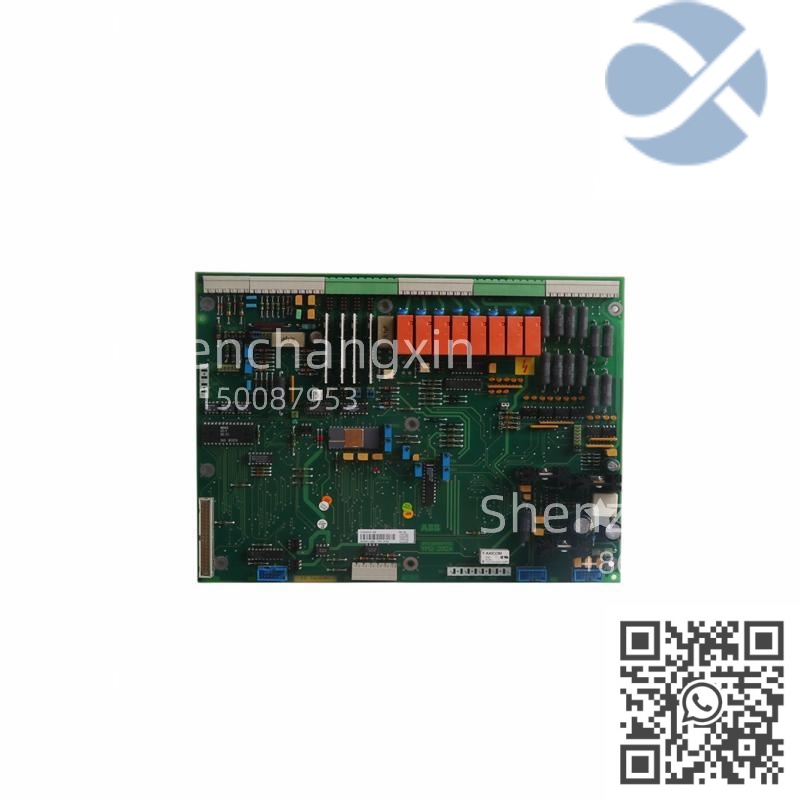

The ABB YPQ110A 3ASD573001A5 is a high-performance I/O baseplate(also known as a terminal base or mounting adapter)designed for the ABB AC 800M distributed control system.It serves as the mechanical and electrical interface between ABB’s S800 I/O modules and field wiring,enabling secure,modular,and maintainable signal connections in industrial automation environments.

Engineered for reliability in harsh process conditions,the ABB YPQ110A 3ASD573001A5 supports hot-swappable I/O modules,integrated diagnostics,and flexible wiring options—making it a foundational component for scalable and serviceable control architectures in power,oil&gas,and heavy industry.

Application Scenarios

During a brownfield modernization at a North Sea offshore platform,engineers needed to replace aging I/O systems without extended shutdowns.They selected the ABB YPQ110A 3ASD573001A5 baseplates to mount new S800 analog input modules alongside existing infrastructure.Thanks to its hot-swap capability and screwless spring-cage terminals,technicians replaced faulty channels in under 90 seconds per module—while the process remained online.Over six months,unplanned downtime due to I/O failures dropped by 75%,and maintenance labor costs fell by 40%.The platform’s automation lead credited the ABB YPQ110A 3ASD573001A5 as“the unsung hero of our digital upgrade.”

Parameter

Main Parameters Value/Description

Product Model ABB YPQ110A 3ASD573001A5

Manufacturer ABB

Product Category S800 I/O Terminal Baseplate(for AC 800M Systems)

Compatible Modules All ABB S800 I/O modules(e.g.,AI810,AO810,DI810,DO810)

Field Wiring Spring-cage terminals(tool-assisted,vibration-resistant)

Backplane Connection DIN-rail mounted with direct mating to S800 I/O bus

Hot-Swap Support Yes—modules can be replaced without powering down the system

Diagnostic Interface Built-in LED indicators for module presence and communication status

Channel Count Support Matches mounted I/O module(typically 8 or 16 channels)

Operating Temperature-25°C to+70°C(suitable for outdoor enclosures)

Protection Rating IP20(when installed in control cabinet)

Certifications CE,UL,cUL,ATEX(for use in hazardous areas when paired with certified I/O)

Technical Principles and Innovative Values

Innovation Point 1:True Hot-Swap Architecture with Signal Hold

The ABB YPQ110A 3ASD573001A5 features gold-plated contact pins and controlled insertion force that maintain backplane communication during module replacement.When used with compatible S800 I/O modules,the controller retains last-known values during swap—preventing process spikes or false trips.

Innovation Point 2:Vibration-Resistant Spring-Cage Terminals

Unlike traditional screw terminals,the spring-cage design in the ABB YPQ110A 3ASD573001A5 ensures consistent clamping force over time,eliminating loosening due to thermal cycling or mechanical shock—critical in marine,mining,and rotating equipment applications.

Innovation Point 3:Integrated Module Presence Detection

A mechanical switch in the ABB YPQ110A 3ASD573001A5 signals to the AC 800M CPU whether an I/O module is fully seated.This prevents configuration mismatches and enables automatic fault reporting if a module is partially dislodged.

Innovation Point 4:Modular Scalability with Zero Backplane Reconfiguration

Users can mix analog,digital,and specialty I/O modules on the same rail using identical ABB YPQ110A 3ASD573001A5 baseplates—simplifying spares management and future expansions without rewiring or chassis changes.

Application Cases and Industry Value

At a large ethylene cracker in Texas,recurring failures in temperature measurement loops were traced to corroded screw terminals in legacy I/O bases.After migrating 300+channels to ABB YPQ110A 3ASD573001A5 baseplates with S800 AI810 modules,the plant eliminated terminal-related faults entirely.Maintenance teams now perform I/O replacements during routine rounds without requesting work permits for de-energization—saving over 200 man-hours annually.The reliability improvement also enabled tighter reactor temperature control,boosting yield by 0.7%.

In a hydroelectric dam in Canada,the ABB YPQ110A 3ASD573001A5 was chosen for its wide temperature tolerance and resistance to humidity-induced corrosion.After five years of continuous operation in an unheated turbine hall,zero baseplate failures were recorded—demonstrating exceptional long-term durability in extreme climates.

Related Product Combination Solutions

ABB AI810(3BSE008516R1):8-channel analog input module—commonly mounted on ABB YPQ110A 3ASD573001A5 for 4–20 mA signals.

ABB AO810(3BSE008517R1):Analog output module for valve positioning,paired with ABB YPQ110A 3ASD573001A5 for reliable actuator control.

ABB DI810/DO810:Digital I/O modules that leverage the same baseplate for discrete signaling in motor control and interlock circuits.

ABB TB820:Shield termination bar—used with ABB YPQ110A 3ASD573001A5 to ground cable shields at the cabinet entry point.

ABB AC 800M PM864A:Controller that communicates with I/O via the S800 bus connected through ABB YPQ110A 3ASD573001A5 baseplates.

ABB 800xA System:Engineering and HMI platform where I/O channels on ABB YPQ110A 3ASD573001A5 are configured,monitored,and diagnosed.

ABB YTA110:RTD terminal block adapter—optional accessory for ABB YPQ110A 3ASD573001A5 when used with temperature modules.

ABB TK801A:DIN rail mounting kit—ensures secure installation of ABB YPQ110A 3ASD573001A5 assemblies in control panels.

Installation,Maintenance,and Full-Cycle Support

Installing the ABB YPQ110A 3ASD573001A5 begins with securing it to a standard 35 mm DIN rail using the integrated latch.Field wires are inserted into color-coded spring terminals using a small flat tool—no torque wrench required—ensuring consistent,tool-verified connections.The baseplate automatically aligns with the S800 backplane;simply slide the I/O module into place until it clicks.For redundant systems,ABB recommends mirrored baseplate layouts to simplify troubleshooting.

Maintenance is minimal but highly efficient:if an I/O module fails,operators can replace it live while the system logs the event.The ABB YPQ110A 3ASD573001A5’s transparent housing allows visual inspection of wire insertion depth and terminal condition without disassembly.No calibration or configuration is stored in the baseplate—making it a true“plug-and-play”mechanical interface.

As an ABB-authorized solutions provider,we supply only genuine,factory-sealed ABB YPQ110A 3ASD573001A5 units,each tested for terminal integrity,contact resistance,and compatibility with S800 modules.Our support includes wiring best practices,DIN rail layout optimization,and rapid-response technical assistance from engineers with hands-on experience in AC 800M deployments worldwide.

Contact us for a customized solution—whether you’re building a new control system,upgrading legacy I/O,or ensuring long-term spares availability,the ABB YPQ110A 3ASD573001A5 delivers the robustness,flexibility,and serviceability your industrial operations demand.