Description

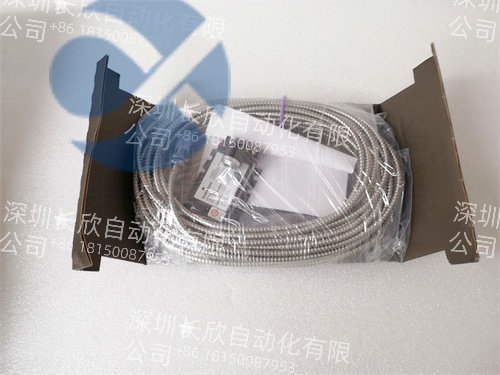

The EMERSON PR6423/002-041 is an 8 mm eddy-current proximity probe engineered for high-fidelity measurement of relative shaft vibration and position in critical rotating machinery.As part of Emerson’s Bently Nevada product line,it delivers exceptional linearity,thermal stability,and noise immunity—making it the sensor of choice for turbine,compressor,and pump monitoring in power,oil&gas,and chemical plants.With a 4-meter integrated coaxial cable and M10 mounting thread,the PR6423/002-041 integrates seamlessly into 3300 and 3500 machinery protection systems.

Application Scenarios

At a Gulf Coast LNG export terminal,operators struggled with inconsistent vibration readings from aging probes on a 40 MW refrigeration compressor,leading to false alarms and unnecessary shutdowns.After replacing legacy sensors with the EMERSON PR6423/002-041,they achieved stable,repeatable measurements even during rapid thermal transients.The probe’s low thermal drift(<0.1%full scale/°C)eliminated signal drift during startup,while its rugged stainless steel tip withstood exposure to humid,saline air.Within six months,nuisance trips dropped by 95%,and the maintenance team gained confidence in their condition-based maintenance program—all thanks to the precision and reliability of the PR6423/002-041.

Parameter

Main Parameters Value/Description

Product Model PR6423/002-041

Manufacturer Emerson(Bently Nevada)

Product Category Eddy-Current Proximity Probe(Vibration/Position Sensor)

Probe Diameter 8 mm

Measurement Range 2.0 mm(80 mils)linear range

Sensitivity 7.87 V/mm(200 mV/mil)±2%

Cable Length 4 meters(integrated,shielded coaxial)

Mounting Thread M10×1 mm standard metric thread

Operating Temperature-40°C to+177°C(-40°F to+350°F)at probe tip

Environmental Rating IP67;ATEX/IECEx optional for hazardous areas;CE,UL,CSA certified

Compatibility Bently Nevada 3300,3500,and System 1 platforms

Calibration Standard Factory-calibrated per ISO 10814;traceable certificate available

Technical Principles and Innovative Values

Innovation Point 1:Ultra-Low Thermal Drift Design–The PR6423/002-041 uses temperature-compensated coil geometry and stable core materials to maintain calibration across extreme thermal cycles—critical for machines that experience frequent startups or ambient swings.

Innovation Point 2:Integrated 4 m Cable with Noise Rejection–Unlike modular designs prone to connector corrosion,the permanently attached coaxial cable eliminates signal degradation and ground loops,ensuring clean data transmission over long runs in electrically noisy environments.

Innovation Point 3:Reverse-Mount Configuration–The sensing coil is positioned at the probe tip’s rear,enabling flush installation in confined spaces(e.g.,between bearing housings)without compromising measurement accuracy—a key advantage in retrofit projects.

Innovation Point 4:API 670&SIL Alignment–Certified for use in safety instrumented systems(SIL 2 capable when used in redundant configurations),the PR6423/002-041 meets stringent requirements for machinery protection in regulated industries.

Application Cases and Industry Value

In a European combined-cycle power plant,a steam turbine suffered repeated bearing wear due to undetected half-speed whirl during low-load operation.Legacy probes lacked the resolution to capture subtle subsynchronous vibrations.After installing the EMERSON PR6423/002-041 on both journal bearings,engineers detected early-stage oil whirl through high-fidelity time-waveform data.They adjusted lube oil temperature setpoints,stabilizing the rotor dynamics.Over three years,bearing replacements decreased from annual to once every five years,saving€650,000 in parts and outage costs.The PR6423/002-041 thus proved essential not just for protection—but for performance optimization.

Related Product Combination Solutions

EMERSON 330980-90-00:Alternative 8 mm probe with different cable length—compatible with same monitor modules as PR6423/002-041.

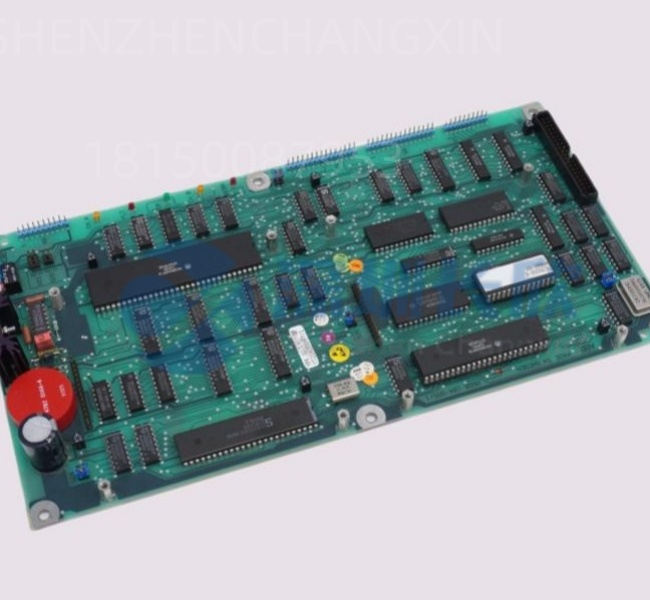

BENTLY 125720-01:Dual-channel vibration monitor that directly interfaces with PR6423/002-041 for real-time protection and trending.

EMERSON 3500/42R:Redundant vibration input module for SIL-rated applications using PR6423/002-041 signals.

EMERSON 133396-01:Keyphasor®module providing rotational reference for orbit analysis when paired with PR6423/002-041 radial probes.

EMERSON PR6444/010-110:Extension cable for custom-length installations if 4 m is insufficient.

EMERSON 3300 XL NSv:Monitor card specifically tuned for PR6423 series probes with enhanced filtering.

EMERSON System 1:Advanced diagnostics platform that uses PR6423/002-041 data for AI-driven failure prediction.

ABB AO2040:While not directly connected,this analog output module can relay processed vibration trends from a DCS that ingests PR6423/002-041 data via Bently systems.

Installation,Maintenance,and Full-Cycle Support

Installing the EMERSON PR6423/002-041 requires precise axial alignment and a clean,non-magnetic mounting surface.The standard M10 thread allows direct insertion into drilled and tapped holes in bearing housings or pedestals.Recommended target material is AISI 4140 steel;calibration cards are provided for other alloys.The optimal air gap is typically 1.0 mm(40 mils),verified using the monitor’s DC gap voltage output(typically 10 VDC at mid-range).

Maintenance involves periodic visual inspection for probe tip damage,cable abrasion,and connector integrity(though the PR6423/002-041 has no field connectors).In harsh environments,protective boots or purge fittings can extend service life.We recommend annual verification of sensitivity using a calibrator or known displacement fixture.Every PR6423/002-041 we supply includes a factory calibration report and is tested for linearity,hysteresis,and frequency response up to 1 kHz.Our technical team supports probe layout planning,gap setting procedures,and integration with existing Bently Nevada or third-party monitoring systems.

Contact us for a customized solution—whether you’re commissioning new turbomachinery,upgrading legacy sensors,or enhancing machine protection compliance,we ensure your EMERSON PR6423/002-041 deployment delivers micron-level precision,decades of reliability,and unmatched operational insight

UFC921A101 3BHB024855R0101 UFC911B106 3BHE037864R0106 UDC920BE01 3BHE034863R0001 XVC770BE101 3BHE021083R0101 KUC755AE105 3BHB005243R0105 LXN1604-6 3BHL000986P7000 LWN2660-6E 3BHL000986P7002 UFC789AE 38HE014022P102 3BHL000734P0003 SLOV4.6/5.3 HIES308461R0012 HIES208441R.. ID8A92485001/022 3BHB009410R000 SG000247 3BHL000986P1006 XVC724BE101 3BHE009017R0102 DKTFM418B 3BHB015651P0001 PU180/63E 3BHB00916230001 HIES308461R0012 FPX86-9345–B 3BHL000986P0006 3BHL000734P0003 SLOV4.6/5.3 UFC921A101 3BHE024855R0101 PPC907BE101 3BHE024577R0101 XVC724BE101 3BHE009017R0102 IEC60129,62271-102 MI-CONP KUC755AE105 3BHB005243R0105 HIES308461R0012 MG160MD2-42FF300-F1 PTC 160℃ TP211 MG160MD2-42FF300-F1 ABB S-073N ALU 3BHB009884R5211 ABB S-093H 3BHB030478R0309 ABB S-123H 3BHB030479R0512 ABB UFC912A101 3BHE039426R0101 ABB 5SHY4045L0001 3BHB018162R0001 ABB S-113N 3BHB018008R0001 W4 KUC755AE105 3BHB005243R0105 HIEE401807R0001 3BHB046719R0008 STRAUB FLEX1L TB820V2 S-053M 3BHB012897R003 *12 3BHB014556R0001 3BHB010823R0002 CDP312R XVC768AE102 UFC789AE101 S-073N KU C755AE105 XVC770BE101 UFC760BE42 PPC907BE UFC760BE43 XVC769AE101 LDMTR-01 UAC389AE02 LTC391AE01 PPC905AE101 UAC383AE01 LDLPTR-01