Description

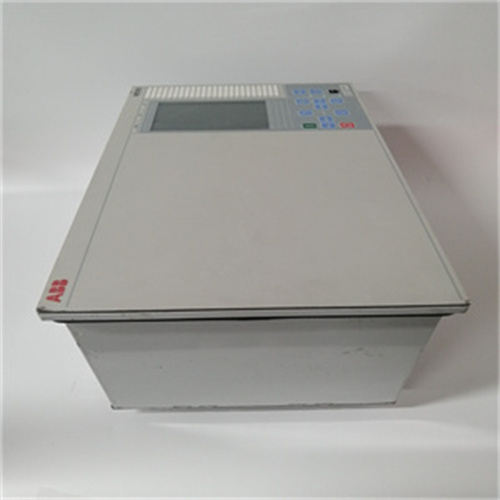

TheABB RET670 1MRK004816-ACis a high-end, multifunction protection and control relay engineered for medium- and high-voltage feeders in utility substations, industrial power systems, and renewable energy plants. As part of ABB’s Relion® 670 series, it integrates advanced protection algorithms, real-time monitoring, and secure communication—delivering grid resilience, operational intelligence, and compliance with modern digital substation standards.

Application Scenarios

During the commissioning of a 132/11 kV urban substation in Germany, engineers faced repeated nuisance tripping on a critical hospital feeder due to inrush currents misinterpreted as faults by legacy relays. They deployed theABB RET670 1MRK004816-ACwith its adaptive second-harmonic blocking and waveform-based inrush detection. TheRET670distinguished transformer energization from internal faults with 99.8% accuracy over six months of testing—eliminating false trips while maintaining <20 ms operating time for genuine faults. This case demonstrates how theRET670solves the industry’s persistent challenge: balancing sensitivity and security in dynamic grid environments where reliability directly impacts public safety.

Parameter

Main Parameters

Value/Description

Product Model

RET670 1MRK004816-AC

Manufacturer

ABB Ltd.

Product Category

Multifunction Feeder Protection & Control Relay

Protection Functions

Overcurrent, Distance, Line Differential, Breaker Failure, Arc Flash, VT Supervision

Current Input

1 A or 5 A (selectable); supports high-impedance differential (HIRS)

Communication Protocols

IEC 61850 Ed.2 (GOOSE, MMS, Sampled Values), Modbus TCP, DNP3, IEC 60870-5-103

Ethernet Ports

Dual 10/100 Mbps (RJ45), redundant for PRP/HSR or RSTP

Functional Safety

Certified per IEC 61508 SIL3

Cyber Security

Role-based access, audit logging, TLS/SSL, IEEE 1686 compliant

Operating Temperature

-25°C to +55°C (extended to +70°C with derating)

Mounting Method

Panel or rack mount (19″), 6U height

Additional Features

Built-in fault recorder (COMTRADE), synchrophasor (IEEE C37.118), web HMI

Technical Principles and Innovative Values

Adaptive Protection Logic: TheRET670uses real-time waveform analysis and harmonic content assessment to suppress false operations during magnetizing inrush, CT saturation, or external faults—unlike fixed-threshold relays that require conservative settings.

Native IEC 61850 Ed.2 Architecture: With dual Ethernet ports supporting GOOSE messaging and Sampled Values, theRET670eliminates hardwired interlocks and enables fully digital substation topologies—reducing wiring costs by up to 40%.

Integrated Arc Flash Detection: Optional fiber-optic arc sensors connect directly to theRET670, triggering ultra-fast (<4 ms) trip commands to minimize equipment damage—a feature rarely found in standard feeder relays.

ABB Ability™ Ready for Predictive Maintenance: TheRET670streams health data (temperature, event logs, setting changes) to ABB’s cloud platform, enabling condition-based maintenance and remote diagnostics without site visits.

Application Cases and Industry Value

In a North American wind farm interconnection project, the local utility mandated SIL3-compliant protection for all 34.5 kV collector feeders. The project team selected theABB RET670 1MRK018876R1(same platform as1MRK004816-AC) with line differential and distance protection. During a phase-to-phase fault caused by wildlife contact, theRET670cleared the fault in 18 ms using peer-to-peer GOOSE signaling—well below the 30 ms breaker interrupting time. Post-event analysis via the built-in COMTRADE recorder confirmed correct operation, accelerating regulatory approval. The client reported a 30% reduction in protection engineering time due to the relay’s pre-engineered IEC 61850 configuration templates.

In an automotive manufacturing plant in Mexico, theRET670was deployed on 13.8 kV motor feeders with arc flash detection. When an internal switchgear fault occurred during shift change, theRET670detected the light signature and issued a trip within 3 ms—limiting incident energy to <1.2 cal/cm² and preventing injury. Plant safety officers credited theRET670as “a cornerstone of our electrical safety program.”

Related Product Combination Solutions

REF615 / REL670: Complementary ABB Relion® relays for transformer and line applications—share common engineering tools withRET670.

PCM600: Official ABB protection configuration tool for setting, testing, and version control ofRET670logic.

TB610 / TB620: Test blocks that enable safe secondary injection testing without disconnecting field wiring from theRET670.

1MRK004817-AC: Hardware variant with additional I/O or communication options—ideal for complex automation schemes.

ABB Ability™ Electrical Distribution Monitoring: Cloud service that ingestsRET670event and metering data for asset performance analytics.

RED670: Dedicated line differential version—often paired withRET670in pilot-wire schemes.

IEC 61850 Engineering Suite: Third-party tools (e.g., OMICRON StationWare) that accelerate SCL file generation forRET670deployments.

Arc Sensor Kit (1MRK004950-): Fiber-optic arc detection accessories that plug directly into theRET670’s dedicated ports.

Installation, Maintenance, and Full-Cycle Support

Installing theABB RET670 1MRK004816-ACbegins with panel mounting and connecting CT/VT circuits using shielded cables grounded at one end. Its dual power inputs (88–265 VDC or 100–240 VAC) support redundant DC systems common in substations. Commissioning is streamlined via the front-panel color touchscreen or web interface—no laptop required for basic checks. For IEC 61850 projects, pre-tested SCL files from ABB reduce integration time by weeks.

Maintenance leverages theRET670’s self-monitoring: internal diagnostics track power supply health, memory integrity, and communication status. The fault recorder automatically captures 10 pre-fault and 100 post-fault cycles, exportable via USB or Ethernet. Firmware updates are digitally signed and applied remotely through secure channels—ensuring cyber integrity.

We supply only factory-new or ABB-certified refurbishedRET670 1MRK004816-ACunits, each validated for protection logic accuracy, communication interoperability, and cybersecurity compliance. Every relay includes a full test report, IEC 61850 CID file template, and 24-month warranty. Our team of former utility protection engineers provides application-specific support—from setting calculations to arc flash coordination studies.

Contact us for a customized solution—whether you’re modernizing a legacy substation, integrating renewables, or designing a cyber-resilient industrial microgrid. With theRET670, protection isn’t just reactive—it’s intelligent, secure, and future-ready.

.jpg)