Description

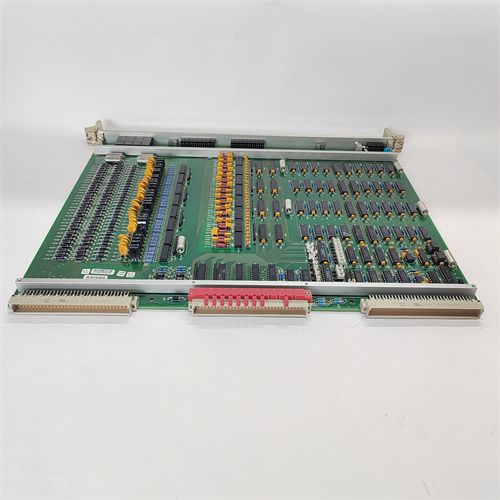

The ABB IMCIS02 is a legacy communication interface module designed for ABB’s MOD 300 and early Advant distributed control systems. This specialized board functions as a critical communication processor, facilitating data exchange between different subsystems within the control architecture. It typically serves as a network interface or protocol conversion module, enabling controllers, operator stations, and other system components to interoperate reliably in demanding industrial environments.

Application Scenarios

In a sprawling oil refinery built in the 1990s, the distillation unit is controlled by a distributed ABB MOD 300 system. The central operator consoles need real-time data from remote process controllers scattered across the unit. The ABB IMCIS02 modules, installed in both the controllers and the workstations, form the backbone of this data highway. Each IMCIS02 manages the reliable, deterministic exchange of thousands of process variables—pressures, temperatures, and valve positions—across the proprietary MOD 300 network. When an operator at an Advant Station changes a setpoint for a critical column temperature, the command travels via the network, processed by the IMCIS02 in the target controller, which then executes the change. The module’s value lies in its flawless, low-latency communication, ensuring that the operator’s view is always synchronized with the actual process, a non-negotiable requirement for safe and efficient refinery operation. Its failure would isolate sections of the control system, creating dangerous blind spots.

Parameter

Technical Principles and Innovative Values

The ABB IMCIS02 was a key enabler of the distributed, yet unified, architecture that defined the MOD 300 and early Advant systems, offering specific innovations for its era.

Innovation Point 1: Dedicated Communication Processing. In an era of limited CPU power, the IMCIS02 offloaded the intensive task of network protocol management from the main controller processor. By handling message routing, data packaging, error checking, and network access on dedicated hardware, it ensured that the real-time control functions of the host controller (like an AC 450) remained deterministic and unaffected by network traffic loads. This separation was fundamental to achieving robust, scalable distributed control.

Innovation Point 2: Deterministic System Network Facilitation. The module was engineered for ABB’s proprietary, deterministic system networks (like the Process Network in MOD 300). It managed token-passing or other deterministic media access methods, ensuring guaranteed data delivery times between nodes. This was critical for coordinating control across multiple controllers and for ensuring that operator displays were updated with consistent, time-aligned data, a cornerstone of effective supervisory control.

Innovation Point 3: Transparent System Integration. The IMCIS02 was designed as a core, transparent component of the system fabric. Its installation and configuration were deeply integrated into the MOD 300/Advant system software. Engineers did not need to program low-level network drivers; instead, the module was recognized as part of the system’s “node,” automatically establishing its communication paths. This significantly reduced commissioning complexity and improved overall system reliability.

Application Cases and Industry Value

Case Study: Legacy Power Generation Control System Life Extension, USA. A combined-cycle gas turbine power plant continued to rely on its original ABB MOD 300 system for critical boiler and turbine control. As the system aged, sourcing spare parts became a high-stakes challenge. A failure of an IMCIS02 board in a main fuel control cabinet threatened to disrupt the communication link, potentially forcing a unit offline. The plant’s maintenance team, in partnership with a specialized industrial automation supplier, located and procured a refurbished and fully tested IMCIS02 module. The swap was performed during a planned turbine outage. The system recognized the new board, and communication was restored seamlessly. This intervention avoided an estimated $500.000+ revenue loss from an unplanned outage and extended the life of the proven, stable control system for several more years, demonstrating the immense value of sustaining legacy components.

Case Study: Pharmaceutical Batch Process Migration Support, Europe. A pharmaceutical manufacturer embarked on a multi-year migration from an Advant system to a modern DCS. During the phased transition, the legacy system needed to remain fully operational for ongoing production. A proactive audit identified aging IMCIS02 boards as a potential single point of failure. The company strategically purchased and stocked a set of tested IMCIS02 spares. When one module in a fermentation control subsystem began showing intermittent errors, it was replaced preemptively during a scheduled batch cleaning. This “like-for-like” swap required no software changes and zero process interruption, ensuring continuous GMP-compliant production. The IMCIS02’s role as a stable, swappable component was crucial in enabling a low-risk, controlled migration strategy.

Related Product Combination Solutions

The ABB IMCIS02 functioned as a node within the broader MOD 300/Advant ecosystem. Key related components include:

Advant Controller AC 450 / AC 410: The primary process controllers that housed IMCIS02 modules to connect to the system network.

Operator Station (OCS) Consoles: The operator interface workstations that also contained IMCIS02 (or similar) boards to access the control network.

NPM/PM/APM Controllers (MOD 300): The earlier generation of MOD 300 controllers that utilized similar communication processor modules for network integration.

MasterBus 300 (MB300): The high-speed, token-passing data highway that connected MOD 300 subsystems, with the IMCIS02 acting as a node on this bus.

Communication Gateway Modules (e.g., for serial links to PLCs): Other modules that handled connectivity to subordinate systems, working alongside the IMCIS02 which handled core system integration.

System Software (MOD 300/Advant): The configuration and runtime environment (like Batch 300) that relied on the communication infrastructure provided by modules like the IMCIS02.

Installation, Maintenance, and Full-Cycle Support

Installation of the ABB IMCIS02 is a specialized task for trained personnel familiar with legacy ABB systems. It requires a complete and safe power-down of the host controller or station. The module is carefully inserted into its designated slot in the chassis, ensuring proper alignment with the backplane connectors. Physical network cabling (often coaxial or twinaxial for older networks) is connected to its port. Upon power-up, the system software typically recognizes the module. Configuration is minimal at the board level but is deeply tied to the overall system configuration managed by the MOD 300/Advant engineering software, where the node’s address and network parameters are defined.

Routine maintenance is passive, focusing on ensuring the host chassis has adequate cooling and clean power. The primary diagnostic indicators are the module’s status LEDs and system-level network diagnostics available on the engineering or operator station. A failure usually manifests as a loss of communication to/from that specific node. Replacement involves swapping the module with an identical, configured unit. We specialize in supporting legacy ABB systems. We can supply fully refurbished, tested, and guaranteed IMCIS02 modules. Our services include compatibility verification, technical advice for replacement procedures, and system health checks to help you maintain the operational integrity of your critical legacy control infrastructure efficiently and cost-effectively.

Maintaining the heartbeat of your legacy MOD 300 or Advant system is critical. Contact us for reliable sourcing, expert support, and lifecycle solutions for the ABB IMCIS02 and other legacy communication modules.