Description

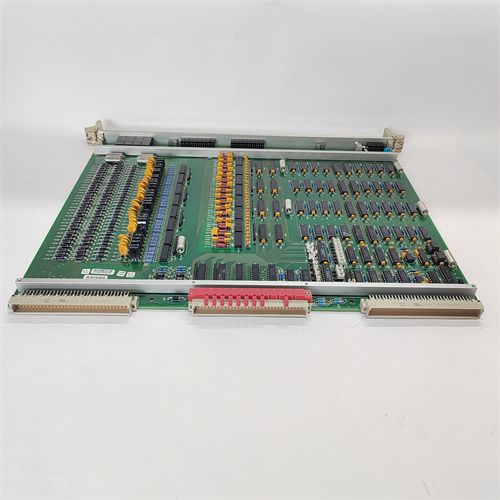

The ABB IMMFP01 is a high-performance fieldbus communication processor module designed for the ABB AC 800M and Symphony Plus distributed control systems. Acting as a master interface, it enables the controller to communicate with remote I/O stations, intelligent field devices (e.g., drives, valves, transmitters), and third-party subsystems over industrial protocols such as PROFIBUS DP, Modbus RTU, and others via RS-485. The IMMFP01 serves as the backbone for distributed automation architectures requiring real-time, deterministic data exchange.

Application Scenarios

At a large-scale pulp & paper mill in Finland, legacy motor control centers were causing bottlenecks due to hardwired DI/DO signals consuming excessive cabinet space. Engineers deployed the ABB IMMFP01 to connect over 200 ABB ACS880 drives and remote I/O racks via PROFIBUS DP. The result? A 70% reduction in wiring, faster diagnostics through integrated drive parameters, and sub-10ms cycle times across the network. When a drive fault occurred, operators pinpointed the exact unit from the IMMFP01’s diagnostic buffer—without leaving the control room. The IMMFP01 didn’t just modernize the system; it redefined operational visibility.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Protocol Flexibility in a Single Module

The IMMFP01 can be configured via Control Builder M to operate as a PROFIBUS DP master for remote I/O or as a Modbus RTU master to poll legacy meters—eliminating the need for external gateways.

Innovation Point 2: Integrated Diagnostics & Error Logging

Built-in status LEDs and a 1.000-event diagnostic buffer allow rapid troubleshooting of bus faults, device timeouts, or parity errors—directly visible in 800xA or via service tools.

Innovation Point 3: Deterministic Real-Time Performance

With hardware-accelerated protocol handling, the IMMFP01 maintains consistent cycle times even under heavy network loads—critical for motion coordination and fast interlocks.

Innovation Point 4: Seamless Redundancy for Mission-Critical Loops

In redundant AC 800M systems, two IMMFP01 modules synchronize state information, enabling bumpless failover if the primary fieldbus processor fails.

Application Cases and Industry Value

In a North American combined-cycle power plant, boiler feed pump control relied on dozens of analog signals from remote skids. By replacing hardwiring with PROFIBUS DP networks managed by dual-redundant ABB IMMFP01 modules, the plant reduced commissioning time by 6 weeks and cut I/O cabinet footprint by 40%. During a grid disturbance, the IMMFP01 maintained communication with all 12 feedwater control valves—ensuring stable drum level despite voltage sags. Post-upgrade, maintenance costs dropped 35% due to predictive alerts on field device health. The project team concluded that the IMMFP01 “delivered more value in integration than any single I/O card ever could.”

Related Product Combination Solutions

ABB CI854A: PROFIBUS DP communication interface—alternative for non-master applications; IMMFP01 offers superior performance as a true master

ABB AO810 / DI810: Local I/O modules—complement IMMFP01 in hybrid architectures combining local and remote signals

ABB AC 800M PM864A: Controller CPU—provides processing power to manage IMMFP01 data flows and logic execution

ABB 800xA System 800: Unified engineering environment—enables full configuration, simulation, and diagnostics of IMMFP01 networks

ABB TB840 / TB820: Terminal bases—used for local I/O where IMMFP01 handles only remote devices

ABB Symphony Plus INFI 90 IO: Legacy I/O—can be integrated via IMMFP01 using Modbus RTU bridges

ABB Asset Optimize: Predictive maintenance suite—uses IMMFP01-collected device data for health scoring

ABB ACS880 Drives: Smart field devices—natively supported over PROFIBUS DP by IMMFP01 with full parameter access

Installation, Maintenance, and Full-Cycle Support

Installing the ABB IMMFP01 requires inserting it into an available slot on the AC 800M S800 I/O rail and connecting shielded twisted-pair cables (e.g., Profibus PA/DP cable) to its screw-terminal RS-485 ports. Termination resistors (typically 220 Ω) must be enabled at both ends of the bus. Configuration is performed entirely in Control Builder M—no DIP switches or external tools needed.

For long-term reliability, ensure proper grounding of cable shields at the controller end only, and avoid running fieldbus cables parallel to power conductors. The IMMFP01 supports online diagnostics: communication status, slave health, and error counters are accessible via 800xA or handheld service units.

We supply genuine IMMFP01 modules (order code typically 3BSE013250R1) that undergo full functional testing—including protocol handshake validation, baud rate accuracy, and redundancy switchover simulation. Each unit includes firmware verification and compatibility assurance for your specific AC 800M revision. Backed by a 12-month warranty and expert fieldbus engineering support, our IMMFP01 ensures your distributed devices stay connected—deterministically and securely.

Contact us for a customized solution—including network topology design, device GSD file management, or global deployment support for multi-plant standardization. Turn your field devices into intelligent, integrated assets with the master that speaks their language.