Description

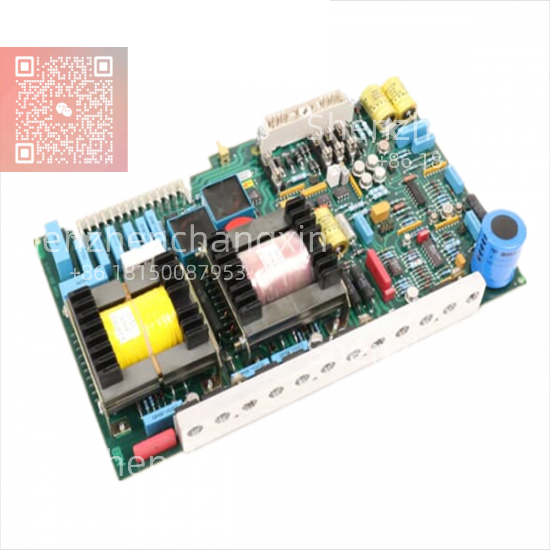

The ABB PFSK102 (YM322001) is a configurable safety relay module, forming a core component of a safety-related control system. It is designed to reliably monitor safety devices (like E-Stop buttons, safety gates, light curtains) and, based on their status, safely disconnect power to hazardous machine functions, thereby achieving a Safe Torque Off (STO) or similar safe state to protect personnel and equipment.

Application Scenarios

In an automated press line, operators need periodic access to clear jams. A hinged safety gate with an interlock switch protects the hazardous area. A fault in the monitoring circuit could allow the press to cycle with the gate open, leading to a catastrophic injury. The ABB PFSK102 safety relay is installed to monitor this gate switch. Its internally redundant and monitored circuits ensure that if the gate is opened, the relay’s safety contacts immediately and reliably cut power to the press’s main drive contactor, bringing it to a stop. Furthermore, it monitors its own output contacts and wiring for faults. If a contact welds or a wire breaks, the PFSK102 will detect the fault, lock out the system, and require a manual reset, preventing an unsafe restart. This scenario demonstrates its role in solving the critical need for functional safety—ensuring a safety function works correctly even when a fault occurs.

Parameter

Technical Principles and Innovative Values

The ABB PFSK102 embodies the principles of fail-safe design and diagnostic coverage, moving beyond simple switching to intelligent, self-checking safety.

Innovation Point 1: Redundant, Diverse, and Monitored Internal Architecture. Unlike a standard relay, the PFSK102 incorporates at least two independent internal switching channels. It uses diverse technologies (e.g., mechanical relays and semiconductor switches) and continuously cross-checks them. If a discrepancy is detected (e.g., one channel is stuck on), the module will fault and drive the outputs to a safe state. This “fault detection” is the core innovation that allows it to achieve high Safety Integrity Levels (SIL) and Performance Levels (PL).

Innovation Point 2: High Diagnostic Coverage (DC) and Safe Failure Fraction (SFF). The module is designed to detect a very high percentage of possible dangerous internal failures (high Diagnostic Coverage). It monitors its own power supply, processor, and output contact status. This high DC contributes to a high Safe Failure Fraction, meaning most failures will be detected and lead to a safe shutdown, rather than remaining undetected and allowing a hazardous situation.

Innovation Point 3: Configurable Logic for Complex Safety Functions. The PFSK102 often includes configurable logic (via hardware wiring, DIP switches, or software). This allows a single module to implement complex safety functions like a two-hand control, mode selector, or monitoring multiple interlock switches in series/parallel. This flexibility simplifies panel design, reduces the number of components, and increases reliability compared to a system built from multiple basic safety relays.

Application Cases and Industry Value

Case Study: Safety System Upgrade for a Robotic Welding Cell

An automotive parts manufacturer needed to upgrade the safety system around a robotic welding cell to meet new corporate safety standards (PL d). The existing system used a single-channel relay to monitor the safety gate, offering no fault detection.

Solution & Outcome: A new safety circuit was designed around an ABB PFSK102 module. It was configured to monitor a dual-channel safety gate switch (with N.O. and N.C. contacts) and a dual-channel E-Stop button. The PFSK102’s redundant inputs and internal monitoring created a Category 3. PL d system according to ISO 13849. After installation, during a routine test, a fault was simulated by shorting one channel of the gate switch. The PFSK102 immediately detected the discrepancy, triggered a safety shutdown, illuminated a fault indicator, and locked out the system until a qualified technician investigated and performed a manual reset. The plant safety engineer stated: “The PFSK102 didn’t just make us compliant; it gave us confidence. We now have diagnostics that tell us ifthe safety system is healthy, not just thatit worked the last time someone opened the gate.”

Related Product Combination Solutions

The ABB PFSK102 is the central logic unit in a complete safety system, interfacing with various field devices and final switching elements.

Safety Input Devices: Dual-channel E-Stop buttons, safety gate switches (with N.O. and N.C. contacts), safety light curtains, laser scanners, and two-hand control stations. These provide the safety signals to the PFSK102.

Safety Output Devices / Actuators: The safety contacts or OSSDs of the PFSK102 are typically wired to the coil circuit of a main contactor or safety relay (like an ABB AF series contactor with forced-guided contacts) that disconnects power to motors, or directly to drives with a Safe Torque Off (STO) input.

Diagnostic & Indication Devices: Fault reset buttons with enabling switches, beacon stack lights, and HMI displays can be connected to the auxiliary signaling contacts of the PFSK102 to provide operator feedback.

Safety PLCs (e.g., ABB AC 500-S): For larger, more complex safety systems, multiple PFSK102 modules or their signals may interface with a safety PLC that coordinates multiple safety functions.

Standard 24V DC Power Supply: A reliable, possibly redundant, 24V DC power supply (e.g., an ABB CP series) is required to power the PFSK102 logic.

Installation, Maintenance, and Full-Cycle Support

Installation of the ABB PFSK102 must be performed by qualified personnel following all applicable safety standards and the manufacturer’s instructions. It involves mounting on a DIN rail, connecting the 24V DC power, wiring the safety input devices (often in a dual-channel configuration), and connecting the safety outputs to the final switching elements (e.g., contactor coils). A critical step is the functional safety validation, which includes checking all safety functions, testing the reset circuit, and verifying that faults are correctly detected and indicated. Proper documentation (wiring diagrams, FMEA) is essential.

Routine maintenance involves periodic testing of the entire safety function, as required by law (e.g., annually). This includes actuating all safety devices (E-Stops, gates) to ensure they cause a shutdown and checking that the reset function works as intended. The PFSK102’s diagnostic LEDs (Power, Run, Fault, Channel Status) are the first point of inspection. If a fault is indicated, the system is locked in a safe state. Troubleshooting involves using the manual to interpret the LED codes, checking field device wiring for shorts/opens, and verifying the external contactor. Our full-cycle support includes assistance with safety system design to achieve the required SIL/PL, supply of certified safety components, and guidance on validation and periodic testing procedures to ensure your safety system remains effective and compliant throughout its lifecycle.

Contact us for expert support in designing, sourcing, and validating your machine safety system with the reliable ABB PFSK102 safety relay.