Description

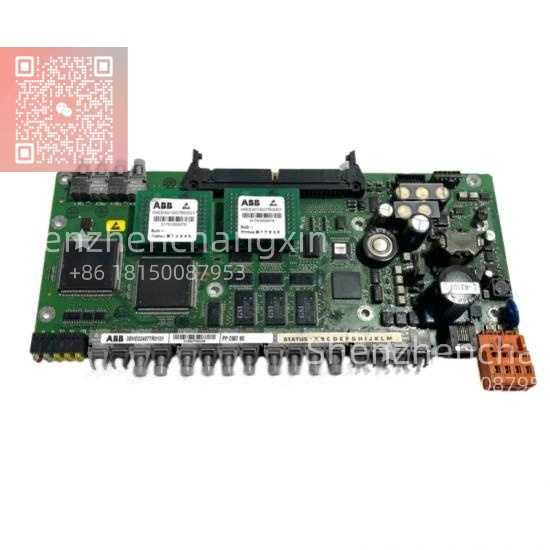

The ABB PMC916 is a sophisticated, fully digital protection relay designed specifically for the comprehensive protection of synchronous generators. It integrates multiple protection functions, control features, and monitoring capabilities into a single, advanced device, safeguarding generators of all sizes and types in hydro, thermal, and industrial power plants.

Application Scenarios

In a 50MW hydroelectric power plant, the generator is the most critical and expensive asset. A fault such as a stator winding short, loss of excitation, or unbalanced loading can cause catastrophic damage within seconds, leading to months of downtime and massive repair costs. The ABB PMC916 is installed in the generator control panel. It continuously monitors electrical parameters like current, voltage, frequency, and power. If a developing internal fault is detected—for instance, a differential current indicating a turn-to-turn short—the relay’s advanced algorithms process the data in milliseconds. It can issue an alarm for a warning condition or, in the case of a severe fault, instantly send a trip command to the generator circuit breaker and field breaker, isolating the machine from the grid and removing excitation to prevent further damage. This solves the critical need for ultra-fast, reliable, and selective protection to prevent mechanical and thermal damage to the generator.

Parameter

Technical Principles and Innovative Values

The ABB PMC916 represents a shift from discrete electromechanical relays to an integrated, intelligent protection system, offering unparalleled reliability, flexibility, and diagnostic depth.

Innovation Point 1: Integrated Multi-Function Protection with Adaptive Algorithms. The core innovation is consolidating over 20 protection functions into one device. More than simple consolidation, it uses adaptive algorithms. For example, its percentage-restrained differential protection (87G) can compensate for CT saturation and transformer phase shift, providing stability during external faults with through-current and high sensitivity for internal faults. This eliminates the need for and coordination between dozens of standalone relays, reducing wiring, panel space, and potential points of failure.

Innovation Point 2: Advanced Digital Signal Processing and High-Resolution Sampling. The relay uses high-speed analog-to-digital converters to sample current and voltage waveforms thousands of times per cycle. This rich data is processed by digital filters and algorithms to extract fundamental components, harmonics, and transients with extreme accuracy. This enables functions like high-resolution fault recording and power-quality analysis, turning the relay from a simple protector into a diagnostic tool for understanding event sequences and system conditions.

Innovation Point 3: Comprehensive Diagnostics and Communication-Centric Design. The PMC916 features extensive self-supervision, continuously monitoring its own hardware and software. It also provides health data for connected equipment, like CT/VT circuit supervision. Its native support for modern protocols like IEC 61850 allows it to communicate detailed fault reports, oscillography, and real-time metering data directly to a SCADA or plant DCS. This enables predictive maintenance, remote diagnostics, and seamless integration into modern digital substations, providing unparalleled visibility into generator health.

Application Cases and Industry Value

Case Study: Protection and Control Upgrade for an Industrial Co-Generation Plant

A chemical plant with a 20MW gas turbine co-generation system relied on an aging panel of discrete protective relays. The system suffered from a non-selective trip that shut down the entire plant during a grid disturbance, causing massive production losses. Diagnosing the cause was nearly impossible due to a lack of event data.

Solution & Outcome: The plant replaced the entire relay panel with a single ABB PMC916 unit. It was configured to provide all necessary protection (differential, overcurrent, reverse power, loss of excitation) and integrated automatic synchronizing (25) for smooth grid reconnection. Six months later, another grid disturbance occurred. The PMC916 correctly identified it as an external fault and remained stable, preventing a plant trip. The built-in fault recorder captured the complete waveform data, allowing engineers to analyze the event. The plant manager reported: “The PMC916 paid for itself by preventing a single major trip. The event records alone are invaluable. We now have confidence in our protection and can prove our generator’s response to the grid operator.”

Related Product Combination Solutions

The ABB PMC916 is the central intelligence in a complete generator protection and control scheme.

Current Transformers (CTs) & Voltage Transformers (VTs): High-accuracy, class-matched instrument transformers that provide scaled-down signals to the relay’s analog inputs.

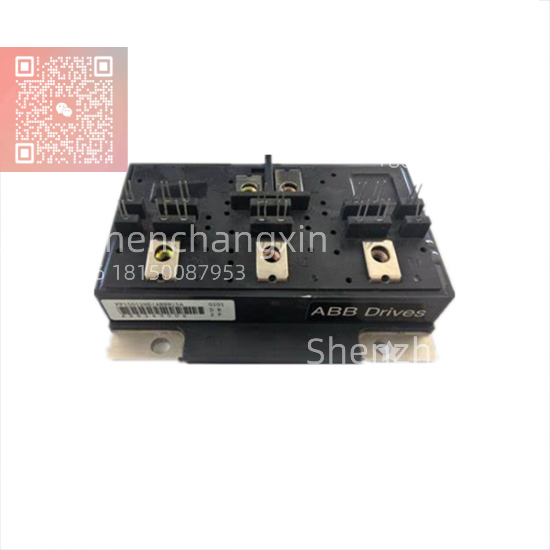

Generator Circuit Breaker (GCB) & Field Breaker: The primary switching devices that the PMC916’s trip outputs command to open in a fault condition.

Synchronizing Equipment: While the PMC916 can include the sync-check function (25), it may interface with an automatic synchronizer for closing the breaker at the precise moment.

RTU/SCADA/Control System: The supervisory system that communicates with the PMC916 via IEC 61850 or Modbus to collect data, alarms, and control the relay remotely.

Test Switches & Blocks: Isolating test switches allow for safe secondary injection testing of the PMC916 without disconnecting CT circuits.

Station Battery & DC Supply: Provides a secure, uninterruptible power source for the relay and trip circuits.

Communication Gateway/Network Switch: Facilitates the integration of the PMC916 into the plant’s communication network for data integration.

Installation, Maintenance, and Full-Cycle Support

Installation requires expertise in protection engineering. It involves mounting the relay in the panel, carefully wiring the CT/VT circuits (ensuring proper polarity and shorting facilities), connecting binary inputs/outputs for trip/alarm/status, and establishing communication links. The crucial phase is configuration and testing using dedicated software (e.g., ABB PCM600). This involves setting all protection function parameters, defining logic, and performing primary injection tests to verify the complete protection chain from CT to trip coil.

Routine maintenance involves periodic visual inspections, verifying relay health via the front-panel display or software, and checking the status of the DC supply. The most important activity is functional testing at regular intervals (e.g., annually) using a secondary injection test set. This test validates the accuracy and operation of each protection function without requiring a generator outage. The relay’s event log and disturbance recorder are invaluable for post-event analysis. Our support covers the full lifecycle: from initial system design and coordination studies, supply of the relay and test equipment, on-site commissioning assistance, to ongoing technical support, firmware updates, and training for your protection engineers.

Contact us for a comprehensive solution for your generator protection needs, from engineering consultation and supply of the ABB PMC916 relay to full testing and commissioning services.