Description

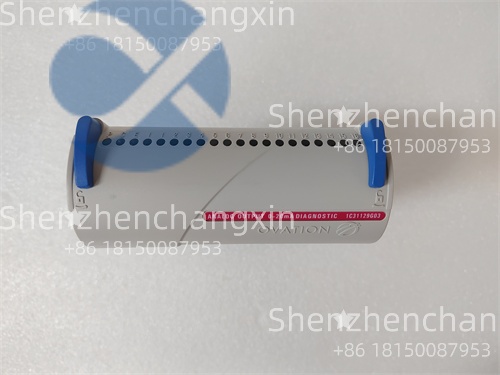

The EMERSON 1C31129G03 is a 32-channel digital input (DI) module engineered for the Ovation™ distributed control system (DCS), widely deployed in power generation, oil & gas, and heavy industrial applications. Designed for high-reliability environments such as turbine halls, boiler controls, and switchyards, this module interfaces with field devices like limit switches, relay contacts, breaker auxiliary switches, and safety interlocks—converting real-world on/off states into secure, time-stamped logic signals for the Ovation controller.

A key feature of the 1C31129G03 is its “wetted” 48 V DC input design, where the module supplies its own interrogation voltage to dry contacts—eliminating dependency on external power sources and ensuring consistent signal detection even in degraded wiring conditions.

Application Scenarios

At a 1.300 MW nuclear power plant in the southeastern U.S., intermittent loss of condensate pump status signals caused unnecessary automatic transfers to standby units—increasing mechanical wear and operator workload. Root cause analysis revealed that aging dry-contact wiring had developed high resistance, preventing reliable detection by legacy 24 V DI cards. The plant upgraded to EMERSON 1C31129G03 modules, which use an internal 48 V DC wetting voltage to overcome contact film resistance and cable degradation. Within weeks, all phantom “pump off” events ceased. During a subsequent surveillance test, the 1C31129G03 correctly identified a failing auxiliary contact on Pump B—allowing replacement during a refueling outage. “It didn’t just read the contact—it energized it into telling the truth,” said the I&C supervisor. This proactive reliability is why the 1C31129G03 is specified in Emerson’s nuclear-grade Ovation reference architectures.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Wetted 48 V DC Input Architecture

By sourcing its own higher-voltage interrogation signal, the 1C31129G03 penetrates oxide layers on aged contacts and compensates for long cable runs—ensuring fail-safe detection where standard 24 V modules falter.

Innovation Point 2: Nuclear-Grade Signal Integrity

Designed to meet stringent requirements for safety-related systems in nuclear plants, including single-failure criterion compliance and environmental qualification.

Innovation Point 3: Time-Synchronized Event Logging

Each DI transition is timestamped with microsecond accuracy using Ovation’s synchronized clock—critical for post-event sequence-of-events (SOE) analysis.

Innovation Point 4: Seamless Ovation Asset Hierarchy

Modules and channels appear in the plant structure tree, enabling operators to view “Channel 24: Open Circuit” directly in the Ovation HMI—accelerating troubleshooting.

Application Cases and Industry Value

In a combined heat and power (CHP) facility in Germany, false trips on steam turbine emergency stop circuits were traced to moisture-induced leakage in outdoor junction boxes. The existing DI system used passive 24 V sensing, which misinterpreted the leakage current as a “closed” contact. After installing EMERSON 1C31129G03 modules with 48 V wetting and 10 ms filtering, the system correctly interpreted the degraded signal as “open”—preventing nuisance trips. Over two heating seasons, unplanned outages dropped by 70%. The plant manager stated: “The 1C31129G03 turned unreliable wiring into a non-issue.”

Related Product Combination Solutions

EMERSON Ovation Controller: Primary DCS platform—native host for 1C31129G03

EMERSON 1C31132G01: 16-channel digital output (DO) module—complements DI for full interlock loops

EMERSON 1C31227G01: Analog input module—for temperature/pressure integration alongside DI

EMERSON Ovation Workbench: Engineering suite—configures, tests, and diagnoses 1C31129G03 modules

ABB REF615: Protection relay—auxiliary contacts feed directly into 1C31129G03 for breaker status

GE Mark VIe: Can interface via Modbus TCP—though native Ovation integration is preferred

Phoenix Contact PLC-RSC: Relay interface—but lacks wetted input and SOE capability

EMERSON 1C31199G01: Terminal base assembly—required for field wiring to 1C31129G03

Installation, Maintenance, and Full-Cycle Support

Installing the EMERSON 1C31129G03 requires mounting in a certified Ovation I/O chassis with proper grounding. Field wiring must use shielded, twisted-pair cable (e.g., Belden 8761), with shields bonded to the chassis ground bar at one end only. For dry-contact devices (e.g., limit switches), no external power is needed—the module provides the 48 V interrogation voltage automatically.

Best practices:

Use the Ovation Workbench “Channel Test” function to verify each input without physical actuation.

Enable open-circuit diagnostics to detect broken wires before they cause logic errors.

Label fiber and cable paths clearly—Ovation supports full asset tagging from field to HMI.

Maintenance includes quarterly visual inspection of channel LEDs and annual verification of contact resistance (<100 Ω recommended). If a module fails, it can be replaced hot—configuration is stored in the controller.

Our technical team provides full lifecycle support—from front-end engineering and FAT validation to on-site commissioning and cybersecurity hardening per NERC CIP. Every 1C31129G03 undergoes functional testing with live dry contacts and simulated faults before shipment. We offer a 24-month warranty and access to Emerson-certified Ovation engineers.