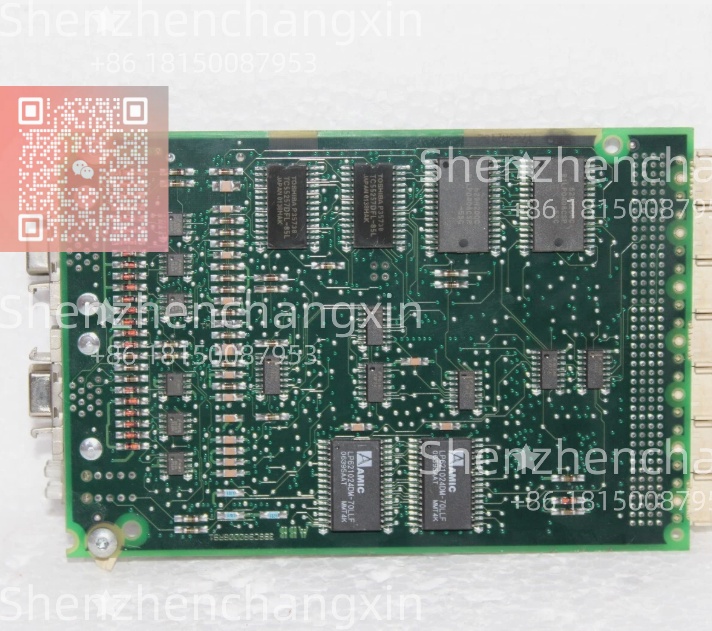

Description

The ABB CI522A 3BSE018283R1 is a high-performance communication interface module manufactured by ABB for its industrial automation systems. This module serves as a critical gateway, implementing the AF100 fieldbus protocol to provide deterministic, real-time data exchange between AC 800M series controllers and distributed S800 I/O stations. Its robust design ensures reliable operation in demanding industrial environments, forming the communication backbone of a distributed control system (DCS) .

Application Scenarios

In a large oil refinery, continuous operation of the distillation unit is paramount. The control system relies on real-time data from hundreds of sensors and actuators connected via remote I/O racks. A communication failure between the central AC 800M controller and these I/O stations could lead to uncontrolled process conditions and significant production loss. Here, the ABB CI522A 3BSE018283R1 demonstrates its value. Configured in a redundant pair, these modules create a fault-tolerant communication link. In a documented case, when a primary CI522A module faulted due to a power anomaly, the backup module performed a seamless switchover in milliseconds. This redundant architecture, central to the CI522A, prevented any disruption to the control loop monitoring critical column temperatures and pressures, thereby avoiding a costly plant shutdown and highlighting its role in ensuring production continuity and safety .

Technical Principles and Innovative Values

Innovation Point 1: Deterministic AF100 Protocol for Real-Time Control. The ABB CI522A 3BSE018283R1 is specialized for the AF100 bus, a high-speed, deterministic protocol designed for industrial control. This provides sub-millisecond response times, which is critical for closed-loop control applications in process automation. Unlike standard Ethernet, the AF100 protocol ensures that critical I/O data is exchanged with precise timing, guaranteeing the stability and responsiveness of the entire control system .

Innovation Point 2: Robust Hardware Design for Mission-Critical Reliability. The module is built for harsh industrial environments. It features 1500V AC isolation, which protects the controller and other system components from voltage surges and ground loops on the field side. Its wide operating temperature range and resistance to vibration and electromagnetic interference (EMI) ensure continuous operation in challenging conditions, from freezing outdoor substations to hot industrial plants .

Innovation Point 3: Advanced Diagnostics and Hot-Swap Capability. The CI522A includes comprehensive diagnostic functions and status LEDs that provide immediate visual feedback on module health and network activity. This allows for rapid fault identification and troubleshooting. Furthermore, its hot-swappable design enables maintenance or replacement of the module without requiring a full system shutdown, significantly reducing downtime and supporting high system availability in continuous process industries .

Application Cases and Industry Value

Case Study: Automotive Assembly Plant Modernization. A European automotive manufacturer upgraded its production line to integrate new ABB robots with existing AC 800M controllers. The legacy communication modules caused data delays, leading to synchronization errors in robotic arms. By deploying the ABB CI522A 3BSE018283R1. the plant established a stable, high-speed AF100 network. This resulted in real-time data exchange, which eliminated synchronization issues. The upgrade led to a 20% increase in production throughput due to reduced downtime and a 15% drop in defect rates, showcasing the module’s direct impact on manufacturing efficiency and product quality .

Case Study: Water Treatment Facility Control System. A North American water treatment plant used ABB S800 I/O modules to monitor chemical levels and pump operations. Inconsistent communication led to inaccuracies in chemical dosing. The implementation of the ABB CI522A 3BSE018283R1 provided a stable and reliable communication link via the AF100 protocol. This precise data exchange enabled accurate chemical dosing, resulting in a 12% reduction in chemical costs and improved compliance with water quality standards. The module’s built-in diagnostics also minimized maintenance time by alerting technicians to potential issues proactively .

Related Product Combination Solutions

The ABB CI522A 3BSE018283R1 is a key component within a larger ABB ecosystem. For a complete solution, consider these related products :

ABB AC 800M Controller (e.g., PM861): The central processing unit that the CI522A module connects to, executing the control logic.

ABB S800 I/O Modules (e.g., AI810. DI810. DO810): The distributed I/O units that interface with field sensors and actuators, communicating with the controller via the CI522A.

ABB CI854A: An Ethernet communication module that can complement the CI522A by providing connectivity to higher-level supervisory networks (e.g., Ethernet IP).

ABB Power Supply Module (e.g., PS865): Provides stable 24V DC power to the rack containing the CI522A and other modules.

ABB TB840 Terminal Base: Provides the physical mounting and electrical connection points for S800 I/O modules.

Installation, Maintenance, and Full-Cycle Support

Installation and Commissioning: The ABB CI522A 3BSE018283R1 is designed for straightforward installation on a DIN rail within a control cabinet. It is crucial to ensure proper grounding and to route communication cables away from power lines to minimize electrical noise. Before installation, the module’s DIP switches must be set according to the network topology to ensure proper termination. Commissioning is typically quick, as the module is designed for plug-and-play operation with AC 800M controllers and S800 I/O, often taking less than 20 minutes per unit .

Maintenance and Support: Routine maintenance is minimal. Periodic visual inspections every six months to check connections and status LEDs are recommended. The module’s hot-swap capability allows for replacement without system shutdown. Sourcing genuine ABB components is essential for guaranteed compatibility and performance. Comprehensive support is available, including technical consultation, configuration assistance, and a standard warranty, ensuring long-term reliability and access to expert help for integration and troubleshooting .