Description

Description

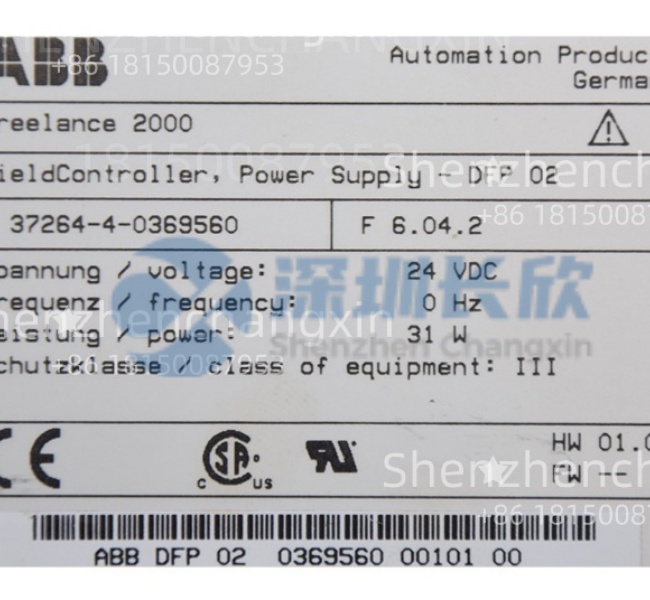

The ABB Freelance 2000 DFP 02 (Order Number: 0369560; Manufacturer Part Number: 37264-4-0369560) is a distributed field processor at the heart of ABB’s Freelance 2000 distributed control system (DCS)—a compact, modular automation platform widely used in chemical processing, pharmaceuticals, water/wastewater, food & beverage, and small-to-midsize power plants.

Based on ABB’s AC 800F controller architecture, the DFP 02 executes real-time control logic, manages local I/O (via TU 8xx terminal units), and communicates with operator stations (DigiNet network) and higher-level systems via Profibus DP, Modbus RTU, or Ethernet. It supports redundant configuration (controller + power supply) for high-availability applications and is certified for use in SIL 2 safety functions (per IEC 61508/61511) when configured with appropriate I/O and software.

This specific revision (0369560) represents a later production variant with enhanced firmware compatibility, improved thermal performance, and extended lifecycle support—making it ideal for modernization, spares replacement, or brownfield expansion of existing Freelance 2000 installations.

Application Scenarios

At a European biopharmaceutical facility, a legacy Freelance 2000 DCS controlled 12 fermenters with strict temperature and pH tolerances. One DFP 01 controller began overheating during summer months, causing sporadic communication losses. The plant replaced it with the ABB DFP 02 (0369560), which offered better heat dissipation and native support for the latest Freelance Engineering Tool (FET) software. The upgrade required no re-engineering—just a drop-in replacement and firmware sync. Over the next two years, the system achieved 99.99% uptime, and engineers leveraged the DFP 02’s enhanced diagnostics to predict a failing power supply before it caused downtime. In aging DCS environments, the DFP 02 0369560 isn’t just a spare—it’s a strategic lifecycle extender.

Technical Principles and Innovative Values

Innovation Point 1: AC 800F Heritage in Compact Form – The DFP 02 inherits the robustness of ABB’s flagship AC 800F but in a cost-optimized package for smaller plants—offering deterministic control, extensive library support, and seamless integration with ABB drives and motors.

Innovation Point 2: Brownfield Modernization Enabler – With backward compatibility to older Freelance I/O and forward compatibility with ABB Ability™ cloud services, the DFP 02 0369560 bridges legacy and digital transformation—delaying full DCS migration costs.

Innovation Point 3: Embedded Diagnostics & Remote Access – Supports SNMP, OPC DA, and web-based status pages for remote monitoring—critical for unmanned water pumping stations or satellite chemical skids.

Innovation Point 4: Safety-Ready Architecture – When paired with F-series safety I/O and configured per IEC 61511. the DFP 02 can execute safety instrumented functions (e.g., reactor shutdown, gas detection response)—eliminating need for separate SIS hardware in mid-risk applications.

Application Cases and Industry Value

A municipal wastewater plant in Germany upgraded 8 aging DFP 01 units to DFP 02 (0369560) during a SCADA modernization. The new controllers enabled OPC UA data publishing to a central historian, allowing predictive maintenance on blower motors. Energy consumption dropped by 12% due to optimized sequencing now possible with the DFP 02’s faster scan times.

In a specialty chemicals plant in India, the DFP 02 controls a batch reactor with exothermic reactions. Its SIL 2 compliance allowed integration of emergency cooling logic directly into the DCS—reducing hardware footprint and validation effort compared to a standalone safety PLC.

Related Product Combination Solutions

ABB TU 810 / TU 811: Terminal units – connect field wiring to DFP 02 I/O modules

ABB AI 810 / AO 810: Analog I/O modules – for temperature, flow, and valve control

ABB DI 810 / DO 810: Digital I/O modules – for motor starters and limit switches

ABB Freelance Engineering Tool (FET): Configuration & programming software

ABB DigiNet Optical Link: Fiber-optic communication between DFPs and operator stations

ABB CP 854: Communication processor – for Modbus TCP/Ethernet integration

ABB System 800xA: Migration target – DFP 02 logic can be partially reused via Control Builder M

ABB Ability™ Asset Performance: Cloud analytics – ingest DFP 02 alarms and trends

Installation, Maintenance, and Full-Cycle Support

Installation requires DIN-rail mounting in a ventilated cabinet, connection to dual 24VDC supplies (for redundancy), and linking to I/O terminal bases and DigiNet network. Always follow ABB’s grounding and shielding guidelines to prevent noise-induced faults.

Maintenance includes periodic firmware updates via FET, backup of application logic, and inspection of cooling vents. The DFP 02 features LED status indicators for CPU, I/O, and network health.

We supply only 100% genuine ABB Freelance 2000 DFP 02 (0369560 / 37264-4-0369560) units—fully tested, with original labels and batch traceability. Our team provides:

Cross-reference validation against your system version

Firmware compatibility checks

Obsolescence alerts and migration planning

Rapid exchange and global shipping

With deep expertise in Freelance 2000 lifecycle management, we help you extend system life, reduce risk, and prepare for future digital integration—without unplanned downtime.