ABB 07AC91 GJR5252300R3101 Technical Specifications

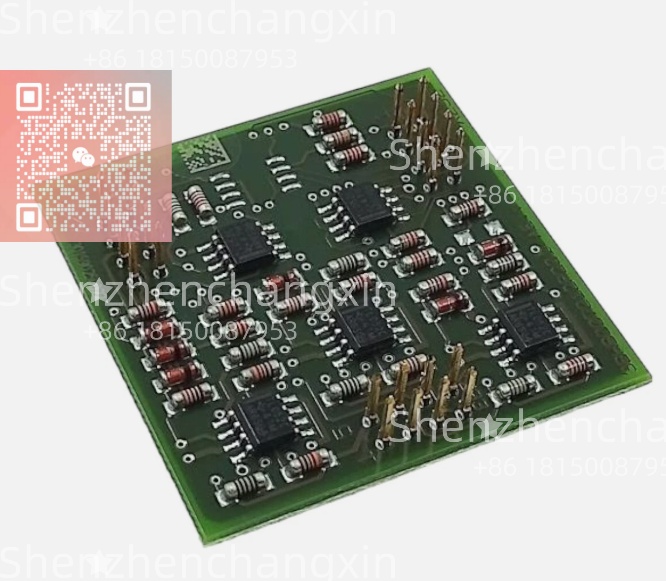

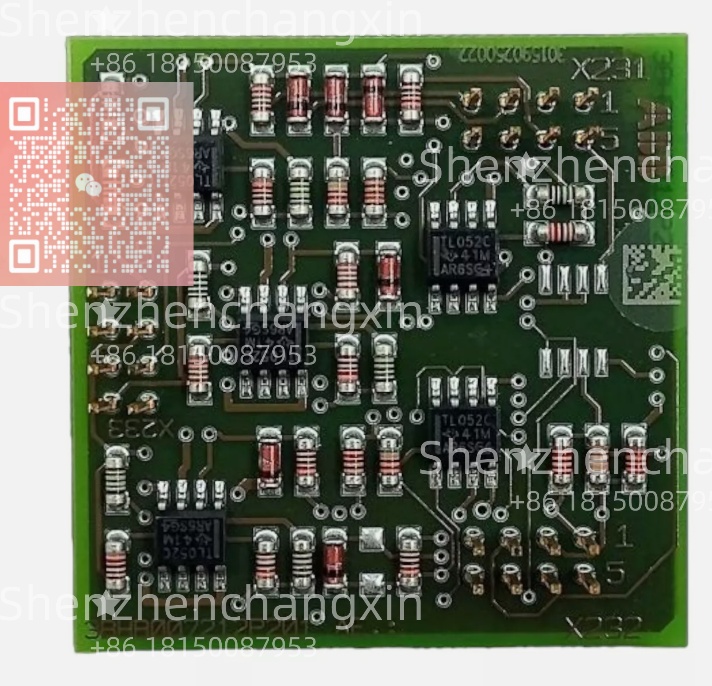

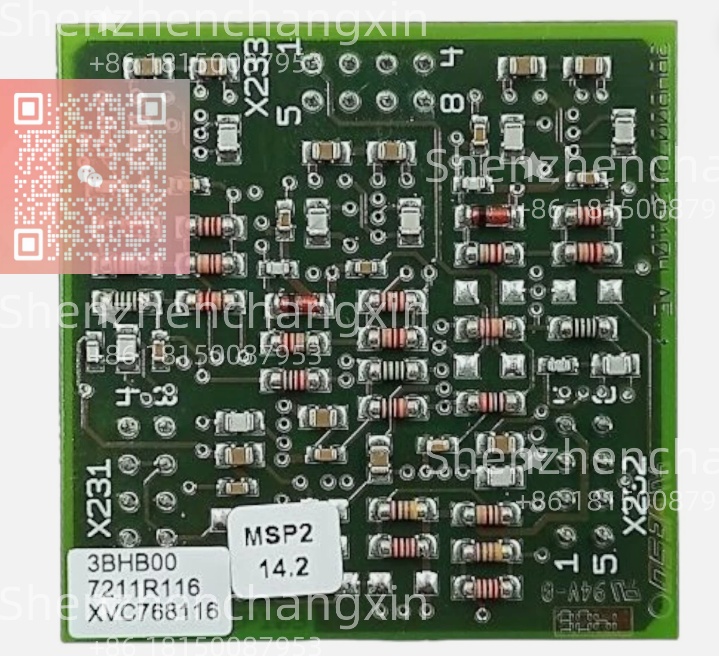

Product Model: ABB E-A Einheit 07AC91 GJR5252300R3101 (KBA L 0055995)

Manufacturer: ABB Process Automation

Product Type: Industrial-grade general-purpose analog I/O module (integrated input + output)

Channel Configuration: 12 independent channels, 8 AI + 4 AO, fully isolated between channels

Analog Input (AI) Parameters:

– Signal Type: 4-20mA DC (two-wire/four-wire compatible), 0-10V DC, independently configurable per channel

– Resolution: 16-bit

– Accuracy: ±0.02% full scale (25℃ reference), ±0.05% full scale (operating temperature range)

– Sampling Rate: 100 times/second per channel, supports batch synchronous sampling of channels

– Isolation Level: 500V AC between channels RMS, 1000V AC RMS to ground, 500V AC RMS for power isolation

Analog Output (AO) Parameters:

– Signal Type: 4-20mA DC (load ≤500Ω), 0-10V DC (load ≥10kΩ), independently configurable for each channel

– Resolution: 16-bit

– Accuracy: ±0.03% full scale

– Response Time: ≤1ms (step signal from 0% to 100%)

– Isolation Level: 500V AC RMS to ground, electrically isolated from AI channels

System Compatibility: ABB AC 800M, Siemens S7-400/1500, Rockwell ControlLogix, and other DCS/PLCs, supporting mainstream industrial buses such as PROFINET and EtherNet/IP

Communication Interface: Standard RJ45 Ethernet port, supports MODBUS TCP/IP and PROFINET IO protocols

Power Supply Voltage: 24V DC (18V~32V wide voltage range), maximum power consumption 15W

Environmental Parameters:

– Operating Temperature: -25℃~+70℃

– Relative Humidity: 5%~95% (non-condensing, no frosting), supports humid and hot environments (40℃/90%RH, 1000 hours of trouble-free operation)

– Protection Rating: IP20 (module body), IP65 (with optional protective housing)

– Interference Immunity: Compliant with IEC 61000-4-2 (ESD), IEC 61000-4-3 (radiated immunity), IEC 61000-4-4 (EFT) standards

Physical Dimensions: 100mm (W) × 180mm (H) × 120mm (D), Weight 0.9kg

Fault Diagnosis: Supports channel overload, signal disconnection, power abnormality, and communication fault detection; LED indicator zone alarm; supports remote diagnostics via web interface

Certification Standards: CE, UL 508, CSA C22.2 No. 14, IEC 61131-2, ATEX Zone 2, IECEx

ABB 07AC91 GJR5252300R3101 Product Overview

The ABB E-A Einheit 07AC91 GJR5252300R3101 is a versatile signal processing solution in the industrial control field. It integrates 8 high-precision analog inputs and 4 stable analog outputs into a single module, solving the problem of accurate acquisition of signals such as temperature, pressure, and liquid level in the field, and directly outputting control signals to drive valves and pump actuators. This eliminates the need for multiple single-function modules, saving half the cabinet space and significantly reducing wiring failure points.

Its “compatibility champion” attribute is particularly popular with established manufacturers: whether it’s ABB’s own AC 800M DCS or Siemens and Rockwell PLC systems, seamless integration is possible through simple configuration of communication parameters via a web interface, without the need for adapter modules. A chemical industrial park built in 2015 had both old ABB systems and newly added Siemens equipment. This module unified signal acquisition and control, eliminating the need for commissioning personnel to familiarize themselves with two different I/O modules, resulting in a 40% increase in efficiency.

Don’t assume high integration sacrifices performance—16-bit resolution plus ±0.02% high precision allows for pressure acquisition errors within 0.0005MPa, more accurate than many imported independent modules; the AO channel response time is less than 1ms, ensuring instantaneous execution of valve opening commands from the controller, avoiding process fluctuations caused by lag. One power plant, after replacing its old modules with this, reduced turbine speed control deviation from ±3rpm to ±0.5rpm, directly improving thermal efficiency by 1.5%. This demonstrates the “hard power” of ABB’s original equipment module.

Key Features and Advantages

1. High Integration and High Precision: The integrated 8AI+4AO design achieves AI accuracy of ±0.02% and AO accuracy of ±0.03%, more than 5 times the performance of ordinary modules (AI ±0.1%, AO ±0.2%). In fine chemical reactor control, the temperature signal error is ≤0.05℃, the output heating power signal is stable and without fluctuation, the reaction temperature control deviation is reduced from ±1℃ to ±0.1℃, product purity increases from 98.5% to 99.8%, the premium per ton of product increases by 2000 yuan, and monthly profits increase by 300,000 yuan.

2. Fully Compatible with Multiple Protocols: Supports mainstream protocols such as PROFINET and MODBUS TCP, and is compatible with multiple brands of DCS/PLCs including ABB, Siemens, and Rockwell. A car parts factory, which already had an old ABB AC 800M system, recently added a Siemens S7-1500 PLC. Using the 07AC91 GJR5252300R3101 PLC, they uniformly acquired welding temperature and pressure signals without modifying either system’s program. The web interface configuration completed communication in just 10 minutes, saving 80,000 yuan compared to purchasing dedicated modules, and reducing debugging time from 3 days to 1 hour.

3. Strong isolation and anti-interference, rock-solid stability in harsh environments: Triple isolation between channels, from channels to ground, and from power supply ensures anti-interference meets the highest level of IEC 61000. In a steel mill converter workshop with extremely strong electromagnetic interference, the signal acquired by ordinary modules fluctuated by 3℃, while the temperature signal acquired by this PLC fluctuated by less than 0.1℃. In the control cabinet of an open-pit coal mine in Northeast China, operating continuously for 6 months at -20℃ without a single connection failure, it is far more reliable than the “low-temperature crash” problem of ordinary modules.

4. Intelligent Diagnosis for Easy Maintenance and Quick, Accurate Fault Diagnosis: The module comes with a built-in web diagnostic interface, eliminating the need for dedicated software. A browser is all that’s needed to view the signal values and fault types for each channel. LED indicators are zoned by AI/AO groups; a broken or overloaded channel is indicated by a corresponding indicator turning red. Previously, troubleshooting required a multimeter to test each channel individually, taking half a day to locate the problem. Now, with the web interface and indicator lights, the problem can be found in 5 minutes, freeing maintenance personnel from endless rack-robin work.

5. Wide Voltage and Temperature Range Design for Versatile Applications: A 24V DC wide voltage power supply (18V~32V) allows operation even in remote areas with unstable voltage. Operating temperatures range from -25℃ to +70℃, handling sub-zero outdoor control cabinets in northern regions and high-temperature workshops in southern steel mills. In a desert oilfield, where daytime temperatures reached 65℃, ordinary modules frequently restarted. Replacing this module with this one resulted in a year of continuous, fault-free operation, ensuring stable crude oil extraction.

The ABB E-A Einheit 07AC91 GJR5252300R3101 is a high-performance integrated analog I/O module engineered for industrial process control, combining 8 analog input(AI)and 4 analog output(AO)channels in a single unit.With 16-bit resolution and±0.02%full-scale accuracy for AI channels,it delivers precise measurement of critical process variables(e.g.,temperature,pressure,level),while its AO channels offer±0.03%accuracy and sub-1ms response time for reliable actuation control.

A key advantage is its multi-protocol compatibility, supporting PROFINET, MODBUS TCP/IP, and other industrial communication standards to seamlessly integrate with major DCS/PLC systems (ABB AC 800M, Siemens S7, Rockwell ControlLogix). This eliminates the need for brand-specific modules, reducing hardware costs and simplifying maintenance for facilities with mixed automation Infrastructure.

Built with triple isolation (channel-to-channel, channel-to-ground, power supply) and compliance with IEC 61000 EMC standards, it operates reliably in electrically noisy and extreme temperature environments (-25°C to +70°C). Integrated intelligent diagnostics—via a web interface and LED indicators—enable fast fault localization, reducing maintenance downtime by 80% compared to conventional modules.

Application Areas

1. Thermal Power Generation Industry: In the boiler feedwater control system of a 600MW thermal power plant, the 07AC91 GJR5252300R3101 collects 8 analog signals such as feedwater pump outlet pressure and economizer temperature, and outputs 4 control signals to adjust the opening of the feedwater regulating valve. 1. **Pressure signal error ≤ 0.0005MPa, regulating valve control response time ≤ 1ms, feedwater flow fluctuation reduced from ±3% to ±0.5%, boiler water level control accuracy improved 6 times, reducing standard coal consumption by 2000 tons annually, saving over 2 million yuan.**

2. **Petrochemical Industry:** In the hydrocracking unit of an oil refinery, it collects 8 channels of simulated signals for reactor temperature and hydrogen pressure, outputting 4 signals to control the heater power and hydrogen inlet valve opening. Hydrogenation reactions have extremely high requirements for temperature and pressure control; deviations exceeding 0.5℃ will affect oil quality. Its high-precision acquisition stabilizes the reaction temperature at 380℃±0.1℃, increasing the yield of high-quality oil from 85% to 92%, producing an additional 700 tons of high-quality diesel per month, earning an extra 560,000 yuan.

3. **Fine Chemical Industry:** In the pharmaceutical intermediate production workshop, it collects 8 channels of simulated signals for reactor temperature and pH value, outputting 4 signals to control coolant valves and feed pump speed. Pharmaceutical intermediates have stringent purity requirements; a temperature deviation exceeding 0.3℃ can introduce impurities. This device collects temperature signals with an error ≤0.05℃, ensuring precise control of the reaction endpoint. Product purity increased from 98.2% to 99.9%, meeting EU export standards. This results in a premium of 3000 yuan per ton, generating an additional 450,000 yuan in monthly profits.

4. Metallurgical Industry: In stainless steel cold rolling workshops, it collects 8 channels of simulated signals for mill roller temperature and rolling pressure, outputting 4 channels to adjust mill reduction and cooling water flow. Stainless steel plate thickness tolerance requirements are ≤±0.01mm. Previously, with ordinary modules, thickness fluctuations were ±0.03mm; after switching to this device, the fluctuation was reduced to ±0.008mm. High-end stainless steel plate production doubled, generating an additional 1000 yuan per ton, resulting in an extra 12 million yuan in annual profits.

Selection Guide/Purchase Recommendations

When choosing the ABB 07AC91 GJR5252300R3101, first clarify your signal requirements: If you need up to 8 channels of analog signal acquisition and up to 4 channels of analog signal output, and the signal type is 4-20mA/0-10V, then this is a “tailor-made” solution. If the number of signals exceeds this, multiple modules can be networked and synchronized via a bus. Don’t be tempted by cheap single-function modules; integrated modules not only save space but also avoid communication delays caused by multiple modules.

Communication protocols must match: For ABB and Siemens systems, prioritize the PROFINET protocol. For domestic DCS or PLCs, the MODBUS TCP protocol is a good choice. During configuration, you can directly select this in the “Communication Settings” section of the web interface; no firmware flashing is required. One customer initially used MODBUS to connect to a Siemens system, resulting in a communication delay of 50ms. After switching to PROFINET, the delay dropped to 1ms. This must be determined based on the host system.

Be sure to buy genuine products: There are many counterfeit products on the market. They may look similar, but their core chips are far inferior. Counterfeit AI accuracy is only ±0.5%, has poor anti-interference capabilities, and will drift under high temperatures. We have tested it; a counterfeit module, after working for 2 hours at 60℃, experienced a 2% AI signal drift, directly causing valve malfunctions. In contrast, the genuine module, after 1000 hours of continuous operation at 70℃, showed an accuracy change of less than 0.01%. When purchasing, check the official ABB serial number or buy from reputable channels like Shenzhen Changxin to avoid being scammed.

Frequently Asked Questions (FAQ)

1. Q: Can the AI channel of this module be directly connected to a thermocouple (K-type) signal? Is a transmitter required?

A: No, it cannot be directly connected. It defaults to acquiring a 4-20mA/0-10V standard signal. Thermocouples are millivolt-level signals and need to be converted to 4-20mA using an ABB TTF200 temperature transmitter before connection. A chemical plant once directly connected a K-type thermocouple…