Description

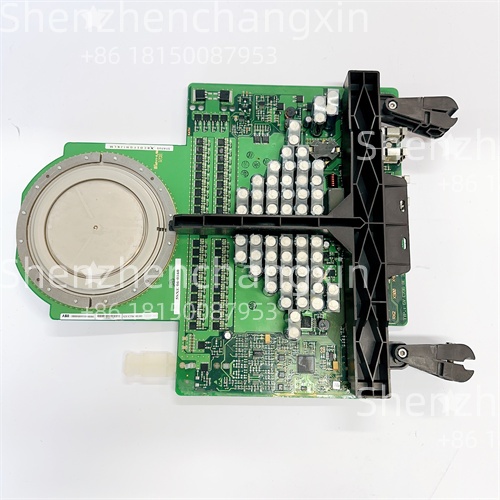

TheABB 5SHX1960L0006(also referenced as3BHB016120R0002)is a high-power,press-pack IGBT module belonging to ABB’s renowned HiPak series.This module is not a stand-alone controller but the fundamental power switching device used as a core component within large-scale industrial equipment,particularly in ABB’s ACS 1000 series of medium-voltage variable frequency drives(VFDs).It acts as the robust”muscle”that efficiently controls electrical power for heavy-duty motors.

Application Scenarios

Deep within a mining operation,a massive conveyor belt driven by a multi-megawatt motor must smoothly accelerate under a heavy load.A standard direct-on-line start would cause immense mechanical stress and power grid disturbance.The ACS 1000 drive,powered by modules like the5SHX1960L0006,provides a controlled,soft start.The IGBT modules within the drive swiftly switch high voltages and currents,precisely controlling the speed and torque of the motor.This scenario underscores the critical role of the5SHX1960L0006in managing immense power,protecting machinery,and ensuring energy-efficient operation in the most demanding industrial environments.

Parameter

Main Parameters

Value/Description

Product Model

5SHX1960L0006/3BHB016120R0002

Manufacturer

ABB Ltd.

Product Category

High-Power IGBT(Insulated-Gate Bipolar Transistor)Module

Series

HiPak(High Power Package)

Module Type

Asymmetric Bridge(typically containing 1 or 2 IGBTs with anti-parallel diodes)

Voltage Rating(Vces)

3300 V

Current Rating(Ic 100°C)

1600 A

Package Technology

Press-Pack(Pressure-mounted)

Key Feature

Short-circuit withstand capability,low thermal impedance

Primary Application

Power conversion in Medium-Voltage Drives(e.g.,ACS 1000)

Cooling Method

Liquid-cooled(requires external heat sink and cooling system)

Weight

Approximately 4.5 kg(module is heavy and robust)

Technical Principles and Innovative Values

TheABB 5SHX1960L0006is engineered for extreme reliability in high-power applications,with several key innovations.

Innovation Point 1:Press-Pack Design:Unlike conventional baseplate modules that use solder,the HiPak5SHX1960L0006uses a press-pack contact technology.This design allows for double-sided cooling,drastically improving heat dissipation and,crucially,allowing the module to fail safely into a short-circuit state,preventing catastrophic failures in the drive system.

Innovation Point 2:High Short-Circuit Withstand Capability:This module is designed to withstand a short-circuit condition for a critical few microseconds.This gives the drive’s control system enough time to detect the fault and safely shut down,protecting the entire power circuit from damage—a vital feature for drive reliability.

Innovation Point 3:Low Thermal Impedance:The advanced internal construction and packaging materials minimize the thermal resistance between the silicon chip and the external heat sink.This enables efficient heat transfer,allowing the5SHX1960L0006to operate at high power levels without overheating,which directly translates to higher system reliability and power density.

Innovation Point 4:Scalable Power Stacking:The robust mechanical and electrical design of the HiPak module allows multiple units like the5SHX1960L0006to be easily connected in parallel or series within a power stack.This scalability is fundamental for building drives with a wide range of power ratings.

Application Cases and Industry Value

Case 1:Pumping Station Retrofit for a Water Utility:A major city’s water pumping station relied on aging fixed-speed drives that consumed excessive energy and required harsh mechanical starters.The station was retrofitted with ABB ACS 1000 drives utilizing the5SHX1960L0006IGBT modules.The new drives allowed for variable speed control of the massive pumps,matching flow to demand.The result was a 30%reduction in energy consumption and the elimination of stressful mechanical starts,significantly extending the pump systems’lifespan.The reliability of the HiPak modules ensured minimal maintenance and uninterrupted water supply.

Case 2:Main Drive for a Metal Rolling Mill:In a hot strip mill,the main rolling stand drive must deliver immense,precisely controlled torque to deform red-hot steel.The failure of a power component here means production halts and costly delays.The5SHX1960L0006modules within the mill’s drive are subjected to rapid and severe load changes.Their robust press-pack design and high current-handling capability ensure consistent performance under these extreme conditions,maximizing mill availability and product quality.

Related Product Combination Solutions

The5SHX1960L0006is part of a larger ecosystem within a drive system.Key related components include:

Gate Unit Board(e.g.,3BHE039203R0102):This is the critical interface that provides the precise voltage and timing signals to switch the IGBTs in the5SHX1960L0006module on and off.It is essential for its operation.

Water-Cooled Heat Sink:A module of this power level generates significant heat.A dedicated liquid-cooled heat sink is mandatory to maintain the5SHX1960L0006within its safe operating temperature range.

Clamping Mechanism:A specialized clamp applies the precise pressure required for the press-pack5SHX1960L0006to make proper electrical and thermal contact.

Other Power Stack Components:In a typical drive,multiple IGBTs work together with other modules like5SNA系列(e.g.,SNAT 3800V modules)to form the complete inverter bridge.

DC Link Capacitors:These large capacitors smooth the DC bus voltage that feeds the5SHX1960L0006inverter stage.

Control Board(e.g.,3BHE024855R0101):The drive’s main control board executes the control algorithms and sends commands to the Gate Units.

Installation,Maintenance,and Full-Cycle Support

Installation and Maintenance:Handling and installing a5SHX1960L0006module is a highly specialized task.It requires a trained technician to ensure the clamping force is applied evenly and correctly,as specified by ABB.The contact surfaces must be perfectly clean,and a specific thermal grease is often required.Maintenance is primarily predictive and preventative:regularly checking the cooling system for leaks or blockages,monitoring coolant quality,and using thermography to check for abnormal heating in the power stack during operation.These steps are crucial for the long-term health of the module.

Our company provides expert support for critical power components like the5SHX1960L0006.We offer genuine,factory-new modules with full traceability.Our technical team can provide guidance on proper handling procedures,compatibility verification,and troubleshooting support to minimize downtime in your drive systems.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

.jpg)