Product Overview

ABB 89NG03 GJR4503500R0001 is a high-performance industrial automation control module,engineered as a core component of ABB’s distributed control systems(DCS)and programmable logic controller(PLC)ecosystems—designed to deliver precise signal processing,reliable I/O control,and seamless communication for critical industrial workflows.As a pivotal”control node”in ABB’s automation portfolio,this module addresses key industrial challenges:ensuring real-time data exchange between field sensors/actuators and central control systems,withstanding extreme operating conditions in power plants,oil&gas facilities,and manufacturing plants,and enabling backward compatibility with legacy ABB automation hardware.

Leveraging ABB’s decades of expertise in industrial control technology,the 89NG03 GJR4503500R0001 integrates multi-channel digital/analog I/O circuits,high-speed communication interfaces,and robust fault-tolerance mechanisms—all optimized for the low-latency,high-availability demands of industrial process control.Its ruggedized design resists temperature fluctuations,electrical interference,and mechanical vibration,while its modular architecture simplifies integration into existing ABB control cabinets.Whether regulating pressure in oil refinery pipelines,monitoring motor performance in manufacturing lines,or controlling energy flow in renewable energy plants,this module ensures consistent,uninterrupted operation—laying the foundation for safe,efficient industrial automation.

Technical Specifications

Parameter Name

Specification

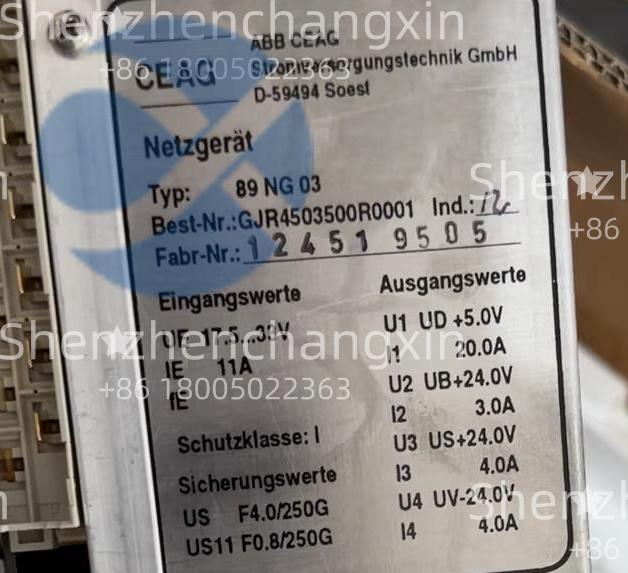

Product Model

ABB 89NG03 GJR4503500R0001

Component Type

Industrial Automation Control Module(Digital/Analog I/O&Signal Processing)

Compatibility

ABB AC 800M DCS,ABB Compact PLCs,ABB Symphony Plus Systems

Core Function

Digital/Analog I/O Control,Signal Conversion,Real-Time Communication,Fault Diagnostics

Circuit Technology

Surface-Mount Technology(SMT);6-Layer PCB(FR-4 High-Temperature Substrate)

I/O Channels

16 Digital Input Channels(24V DC),8 Digital Output Channels(24V DC/2A),4 Analog Input Channels(4-20mA)

Communication Interfaces

Ethernet/IP,PROFINET,Modbus TCP,ABB proprietary PRONETA

Operating Temperature Range

-25°C~+70°C

Storage Temperature Range

-40°C~+85°C

Power Requirements

24V DC±15%,2.5A Max(Typical:1.8A)

Power Consumption

Typical:43.2W;Maximum:60W

Protection Features

Overcurrent Protection(5A per Output Channel),Overvoltage Protection(36V DC),ESD Protection(±25kV Contact),Short-Circuit Protection

Physical Dimensions

150mm×100mm×25mm(L×W×H)

Net Weight

Approximately 320g

Standards Compliance

IEC 61131-2,IEC 61000-6-2,CE,RoHS,UL 508,ATEX Zone 2(Hazardous Area Compatible)

Vibration Resistance

15g(10-2000Hz,3 Axes)

Shock Resistance

50g(1ms Pulse,3 Axes)

MTBF(Mean Time Between Failures)

≥100,000 Hours

Signal Conversion Accuracy

Analog-to-Digital:16-Bit Resolution,±0.05%Full Scale

Main Features and Advantages

Multi-Protocol Communication Flexibility:The module supports industry-leading industrial Ethernet protocols(Ethernet/IP,PROFINET,Modbus TCP)and ABB’s PRONETA for seamless integration into diverse automation networks.This eliminates the need for protocol converters,reducing system complexity and enabling direct communication with PLCs,HMIs,and cloud-based monitoring platforms—critical for smart factory deployments.

High-Density,Versatile I/O Control:With 16 digital inputs,8 digital outputs,and 4 analog inputs,the module handles mixed-signal control tasks(e.g.,monitoring sensor status,triggering actuators,measuring process variables)in a single compact unit.Digital outputs support 2A current per channel,enabling direct control of small motors and solenoids without external relays.

Industrial-Grade Ruggedness:Built with a 6-layer FR-4 PCB substrate,automotive-grade capacitors,and nickel-plated terminals,the module withstands extreme temperatures(-25°C~+70°C),high humidity(95%non-condensing),and corrosive environments(compatible with oil,gas,and chemical vapors).ATEX Zone 2 certification makes it suitable for hazardous areas like oil refineries and chemical plants.

Fault-Tolerance&Diagnostics:Integrated fault-detection mechanisms(overcurrent,short-circuit,voltage anomalies)trigger real-time alerts via PRONETA or Modbus,enabling predictive maintenance and minimizing unplanned downtime.Each I/O channel features individual status LEDs for quick visual troubleshooting—reducing diagnostic time by 70%compared to non-LED-equipped modules.

Backward Compatibility&Scalability:The module is fully compatible with legacy ABB AC 800M and Symphony Plus systems,allowing incremental upgrades of existing control infrastructure without full system replacement.Its modular design supports daisy-chaining of up to 16 modules,enabling scalable I/O expansion for large-scale projects(e.g.,power plant control rooms).

Low-Latency Signal Processing:Equipped with a 32-bit dual-core microcontroller,the module processes I/O signals with≤2ms latency—ensuring real-time response to critical process changes(e.g.,pressure spikes in pipelines,temperature deviations in reactors).This is essential for safety-critical applications where delayed control could lead to equipment damage or operational hazards.

Application Field

ABB 89NG03 GJR4503500R0001 is a versatile control module for industrial automation across sectors.In oil&gas production,it integrates with ABB Symphony Plus systems to monitor and control pipeline pressure:digital inputs track valve positions,analog inputs measure pressure transducers,and digital outputs trigger emergency shutoff valves—ensuring compliance with safety standards(API 570)and preventing leaks.

In power plants(fossil fuel and renewable),the module acts as a distributed I/O node for turbine control:it processes temperature and vibration sensor data(analog inputs),controls fuel injection solenoids(digital outputs),and transmits real-time data to the central DCS via PROFINET.Its ATEX certification allows deployment in gas-fired power plant turbine enclosures.

In manufacturing,the module supports factory automation workflows(e.g.,automotive assembly lines):digital inputs monitor conveyor belt sensors,analog inputs measure robotic arm position,and digital outputs control grippers—integrating with ABB Compact PLCs to optimize production speed and reduce defects.Its vibration resistance ensures stable performance near stamping presses and welding robots.

In water&wastewater treatment,the module controls pump stations and chemical dosing systems:digital inputs detect water level sensors,analog inputs measure pH and chlorine levels,and digital outputs activate pumps and valves.It communicates with SCADA systems via Modbus TCP,enabling remote monitoring and automated adjustment of treatment processes—reducing manual intervention and improving efficiency.

Related Products

ABB AC 800M DCS Controller:Central control unit that pairs with the 89NG03 module for large-scale process control.

ABB HMI Panel 6AV2124-1GC01-0AX0:Human-machine interface for visualizing I/O status and controlling the module via Ethernet.

ABB PRONETA Software:Diagnostic and configuration tool for setting up the module,monitoring faults,and updating firmware.

ABB Shielded Ethernet Cable 3LNE080001R0001:Industrial-grade cable for noise-free communication between the module and PLCs/HMIs.

ABB 24V DC Power Supply 8PS320.100-2:Dedicated power module optimized for the module’s voltage and current requirements.

ABB Terminal Block Kit 1SNA663001R1200:High-density terminal blocks for secure wiring of I/O signals to the module.

ABB DIN Rail Mounting Bracket 1SFA898100R1001:Hardware for installing the module in standard 35mm DIN rail control cabinets.

ABB Calibration Tool 3BHB008454R0001:Device for verifying analog input accuracy and calibrating signal conversion.

Installation and Maintenance

Pre-installation preparation:Confirm compatibility with target ABB automation systems(AC 800M,Compact PLCs,etc.).Gather tools:anti-static wristband,precision torque screwdriver(0.5-1.5 N·m),wire stripper,and ABB PRONETA software(installed on a laptop).Ensure the control cabinet is powered off and grounded to prevent electrostatic damage.Inspect the module for physical defects(e.g.,bent pins,cracked housing)and verify ATEX certification if deploying in hazardous areas.

Installation steps:1.Mount the module on a 35mm DIN rail using the ABB 1SFA898100R1001 bracket—ensure 30mm clearance from heat-generating components(e.g.,power supplies)for airflow.2.Wire I/O signals to terminal blocks:Use shielded cables for analog inputs(ground shields at both ends)and twisted-pair cables for digital signals.Torque terminal screws to 0.8-1.2 N·m to avoid loose connections.3.Connect the 24V DC power supply to the module’s power terminals(verify polarity to prevent reverse damage).4.Establish communication:Connect an Ethernet cable between the module and PLC/HMI,then launch PRONETA to detect the module,assign an IP address,and configure I/O parameters(e.g.,input trigger levels,output current limits).5.Power on the system and run a diagnostic test:Activate test signals via PRONETA to verify input detection and output activation—confirm all LEDs display correct status(green for normal,red for fault).

Maintenance recommendations:Conduct monthly inspections:Visually check terminal blocks for corrosion,loose wires,or overheating(discolored insulation).Use compressed air(low-pressure)to remove dust from the module’s vents—avoid liquid cleaners.Every 6 months,use the ABB 3BHB008454R0001 calibration tool to verify analog input accuracy;recalibrate via PRONETA if deviations exceed±0.05%full scale.In case of faults(red LED activation),use PRONETA’s diagnostic dashboard to identify the issue(e.g.,short-circuit,overvoltage)before replacing components.For hazardous area deployments,schedule annual ATEX compliance checks to ensure no damage to the module’s sealing.

Product Guarantee

ABB 89NG03 GJR4503500R0001 is backed by ABB’s industry-leading 24-month manufacturer’s warranty against material and workmanship defects.Each module undergoes rigorous testing:100,000-hour MTBF validation,temperature cycling(-25°C to+70°C),ESD and surge protection trials,and ATEX hazardous area certification testing.ABB’s global technical support team provides 24/7 assistance for installation,configuration,and troubleshooting—with remote access capabilities to diagnose issues in real time.Extended warranty options(up to 5 years)and expedited delivery of replacement modules minimize downtime for critical automation systems.As a genuine ABB component,it ensures seamless integration with ABB’s automation ecosystem—backed by over 130 years of industrial technology expertise.

选择深圳长欣,享受无忧的售后服务和高品质产品。我们只与行业一线品牌厂商合作。