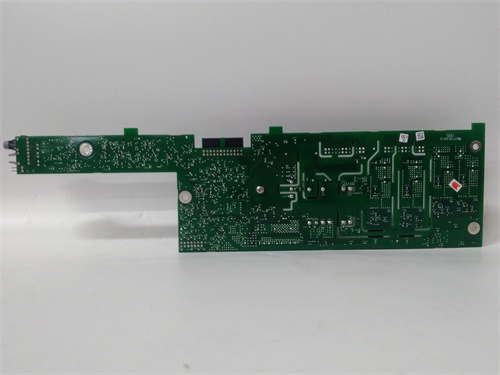

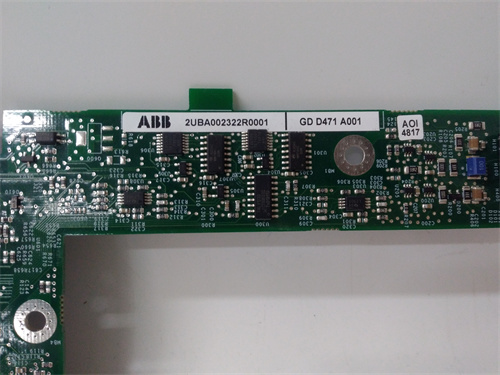

Description

The ABB GDD471A0001 (commonly referenced as GDD471A001) is a high-density, mixed-signal digital I/O module engineered for the ABB AC 800M programmable automation controller within the System 800xA distributed control system (DCS). It provides 16 digital inputs and 16 digital outputs in a single compact module, enabling efficient monitoring and control of binary field devices such as limit switches, solenoid valves, motor starters, and alarm relays.

Designed for industrial robustness and seamless integration, the GDD471A001 supports 24 V DC signals with galvanic isolation, diagnostic capabilities, and hot-swap functionality—making it ideal for continuous-process industries like oil & gas, power generation, chemicals, and mining where reliability and maintainability are critical.

Note: The correct full part number is typically GDD471A0001 (with an extra zero), though it is often abbreviated in documentation and procurement as GDD471A001. Both refer to the same functional module.

Application Scenarios

At a Scandinavian district heating plant, frequent false trips in pump interlocks were traced to aging relay cards with no input diagnostics. After upgrading to the ABB GDD471A001. engineers gained real-time visibility into digital signal health—including open-circuit detection on dry-contact inputs. During a winter peak-load event, a failing pressure switch was flagged before it caused a cascade shutdown, allowing proactive replacement during a planned window. “We used to react to failures,” said the controls lead. “Now, with the GDD471A001. we predict them.” In mission-critical infrastructure, this shift from passive wiring to intelligent I/O transforms operational resilience.

Technical Principles and Innovative Values

Innovation Point 1: True Mixed I/O in One Module

Combining 16 inputs and 16 outputs in a single slot reduces cabinet space by up to 50% compared to separate DI/DO modules—lowering hardware costs and simplifying spares management.

Innovation Point 2: Per-Channel Diagnostics Integrated into 800xA

Unlike basic I/O cards, the GDD471A001 reports individual channel faults (e.g., broken wire, shorted output) directly to the System 800xA operator workplace. Alarms include precise tag names, enabling rapid troubleshooting without panel inspection.

Innovation Point 3: Flexible Wiring for Sinking/Sourcing Topologies

The module supports both NPN (sinking) and PNP (sourcing) field devices through terminal block configuration—eliminating the need for external interface relays in mixed-vendor installations.

Innovation Point 4: Seamless Redundancy and Hot-Swap Support

In redundant AC 800M (PM865) systems, the GDD471A001 can be replaced online without process interruption. State data is mirrored across redundant channels, ensuring continuity of control logic.

Application Cases and Industry Value

Mining Conveyor System (Australia):

Replaced 4 legacy relay racks with 2 AC 800M stations using GDD471A001 modules. Reduced panel footprint by 60%, while real-time belt misalignment and jam detection cut unplanned downtime by 35%.

Combined-Cycle Power Plant (USA):

Used GDD471A001 to monitor boiler flame scanner status (inputs) and control purge valve solenoids (outputs). Its 500 V isolation prevented ground-loop noise from affecting trip logic—critical for NFPA 85 compliance.

Chemical Batch Reactor (Germany):

Leveraged output short-circuit protection to safely drive agitator motor contactors. When a coil short occurred, the module isolated only the faulty channel—keeping the rest of the batch sequence running.

Related Product Combination Solutions

表格

Installation, Maintenance, and Support

Installation:

Mount the GDD471A001 onto a TB840A/TB850A terminal base in an AC 800M I/O pack.

Use shielded, twisted-pair cable for all field connections; ground shield at cabinet only.

Configure input/output type via terminal wiring (no jumpers or software settings needed for voltage level).

Commissioning:

In Control Builder M, assign each channel a tag name, alarm priority, and fail-safe state (e.g., output = OFF on fault). Use the built-in I/O test mode to validate field device response before going live.

Maintenance:

Monitor front-panel LEDs: green = active, red = fault.

Replace failed modules in minutes using hot-swap (in redundant systems).

No calibration required—solid-state design ensures long-term stability.

Every ABB GDD471A001 we supply is tested for full I/O functionality, isolation integrity, and communication with AC 800M CPUs. Units are guaranteed genuine new or premium refurbished with a 12-month warranty. Our team includes ABB-certified engineers who support migration, configuration, and lifecycle management—from FAT to decommissioning.

Contact us for a reliable, high-density digital I/O solution that integrates seamlessly into your ABB System 800xA architecture—with the ABB GDD471A001 as your intelligent link to the field.