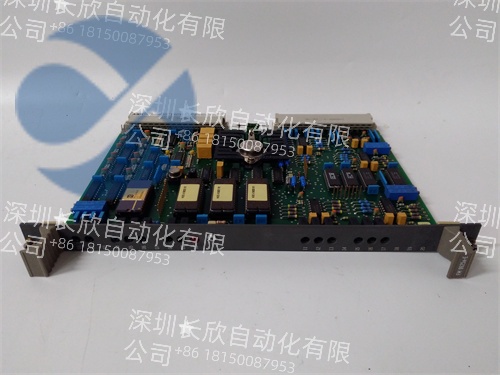

Product Overview

The ABB FM9925a-E HIEE451116R0001 is a high-integrity safety module developed by ABB,specifically engineered for integration with ABB’s Advant OCS(Open Control System)and S800 I/O safety platforms.As a core component of industrial safety instrumented systems(SIS),this module serves as a critical interface between field safety devices(sensors,valves,emergency stops)and the central control system,enabling real-time monitoring of critical process variables and rapid execution of safety actions to prevent catastrophic incidents—such as explosions,chemical leaks,or equipment failures—in high-risk industries.

Distinguished by its SIL 3 certification(per IEC 61508)and robust redundant design,the ABB FM9925a-E supports both digital(24V DC)and analog(4-20mA)I/O signals,making it versatile for diverse safety applications.It can monitor up to 8 analog inputs(for pressure,temperature,flow transmitters)and 8 digital inputs(for emergency stop buttons,safety gate switches),while controlling 4 digital outputs(for emergency shutdown valves,alarms,or pump relays).A key differentiator is its fast response time(≤15ms)from signal detection to safety action,which is critical for time-sensitive processes like gas compression or turbine overspeed protection.

In a typical offshore oil platform SIS,the ABB FM9925a-E HIEE451116R0001 monitors 6 pressure transmitters(analog inputs)on a crude oil pipeline.If pipeline pressure exceeds the safe threshold(e.g.,10,500 psi),the module triggers 3 emergency shutdown valves(digital outputs)within 12ms,preventing pipeline rupture and potential environmental disasters.Its redundant hardware architecture—including dual power supplies and communication paths—ensures no single point of failure,maintaining continuous safety monitoring even if a component malfunctions.

Compared to standard I/O modules,the FM9925a-E incorporates advanced diagnostic features,such as channel-level fault detection,signal drift monitoring,and short-circuit protection.These diagnostics provide early warnings of potential issues(e.g.,a failing temperature sensor or damaged wiring),allowing maintenance teams to address problems proactively.For example,a chemical plant used the module’s drift monitoring to identify a degraded pressure sensor—replacing it during a scheduled outage avoided a 4-hour unplanned shutdown that would have cost$350,000.

Technical Specifications

Parameter Name

Parameter Value

Product Model

ABB FM9925a-E(Order No.:HIEE451116R0001)

Manufacturer

ABB Ltd.(Process Automation Division)

Product Type

Safety Input/Output(I/O)Module for SIS

Compatible Systems

ABB Advant OCS,ABB S800 I/O,ABB 800xA DCS

Safety Certification

IEC 61508 SIL 3;EN ISO 13849-1 PL e;TÜV SÜD Approved

I/O Configuration

-8 Analog Inputs(AI):4-20mA DC(2-wire/4-wire transmitters)-8 Digital Inputs(DI):24V DC(sinking/sourcing)-4 Digital Outputs(DO):24V DC(2A per channel)

Input Accuracy

-Analog(4-20mA):±0.08%of full scale-Digital:±0.5V(threshold for 24V DC)

Response Time

-Analog Input Detection:≤10ms-Digital Input Detection:≤5ms-Output Action Latency:≤15ms(from input trigger to output)

Operating Temperature

-40℃to+70℃(operation);-40℃to+85℃(storage)

Hazardous Area Certifications

ATEX Zone 2(II 3G Ex nA IIC T4 Ga);IECEx Zone 2(Ex nA IIC T4 Ga);Class I,Division 2(UL 1203)

Power Supply

Redundant 24V DC±10%(21.6V–26.4V);Power Consumption:≤10W

Physical Dimensions

120mm(L)×100mm(W)×210mm(H);Rack-Mountable(3U Form Factor for ABB Cabinets)

Weight

0.95kg(2.09 lbs)

Redundancy

Support for 1oo2(1-out-of-2)and 2oo3(2-out-of-3)safety loop architectures;Hot-swappable

Communication

Backplane:ABB SafeLoop Bus(100Mbps);Supports ABB Industrial Ethernet for remote monitoring

Diagnostics

Channel-level short-circuit/overvoltage protection,analog signal drift monitoring,power supply health checks,communication fault detection

Ingress Protection

IP20(suitable for control cabinet installation)

EMI/RFI Immunity

IEC 61000-4-2(ESD±8kV contact);IEC 61000-4-3(Radiated Immunity±10V/m);IEC 61000-4-4(EFT±2kV)

Main Features and Advantages

SIL 3 Certification for Maximum Safety Integrity:The ABB FM9925a-E HIEE451116R0001 is fully certified to IEC 61508 SIL 3—the highest safety integrity level for most industrial applications—validating its ability to operate in safety loops where the probability of failure on demand(PFD)must be≤10⁻³.This certification is achieved through rigorous testing,including extreme temperature cycling,vibration exposure,and fault injection simulations.For example,a nuclear power plant’s auxiliary feedwater system uses the module in a 2oo3 configuration to monitor water level(analog inputs)and control feed pumps(digital outputs).The SIL 3 rating ensures compliance with NRC regulations and provides a 99.99%probability of correctly responding to low-water events,preventing core overheating.

Redundant Design&Hot-Swappability for Uninterrupted Operation:The module features dual redundant power inputs and communication paths to the ABB Advant OCS/S800 I/O system.If one power supply fails or a communication link is disrupted,the backup system takes over seamlessly—ensuring no gap in safety monitoring.Additionally,the FM9925a-E is hot-swappable:technicians can replace a faulty module without shutting down the SIS or control system.A refinery in Texas leveraged this feature when an analog input channel failed:the redundant channel assumed control immediately,and the faulty module was replaced in 18 minutes—avoiding a 3.5-hour shutdown that would have cost$420,000 in lost production.

Multi-Signal Versatility for Flexible Integration:Unlike single-function safety modules,the FM9925a-E combines analog and digital I/O in a single unit—supporting 8 analog inputs(4-20mA),8 digital inputs(24V DC),and 4 digital outputs(24V DC).This eliminates the need for multiple specialized modules,reducing control cabinet space by up to 35%and simplifying wiring.A chemical plant using the module in its reactor safety system replaced 3 separate modules(1 analog,2 digital)with a single FM9925a-E,cutting installation time by 28%and lowering long-term maintenance costs.The analog inputs also support both 2-wire and 4-wire transmitters,making it compatible with legacy and modern field devices—avoiding costly transmitter upgrades.

Advanced Diagnostics for Predictive Maintenance:The module’s built-in diagnostics monitor 110+parameters,including analog signal drift,digital channel continuity,and power supply voltage.For analog inputs,it tracks subtle signal shifts(e.g.,a pressure transmitter’s output drifting from 12mA to 12.5mA for the same pressure),alerting operators to sensor degradation before it affects process safety.For digital channels,it detects short circuits,open circuits,and overcurrent conditions—isolating faulty channels to prevent cascading failures.A pharmaceutical manufacturer used these diagnostics to identify a failing temperature sensor in its batch reactor system:the module triggered an alert,and the sensor was replaced during a scheduled maintenance window—avoiding a batch rejection(costing$130,000)due to inaccurate temperature control.

Application Field

The ABB FM9925a-E HIEE451116R0001 is widely deployed in industries where safety is mission-critical—with key applications in oil&gas,chemicals,power generation,and pharmaceuticals.In oil&gas production(onshore/offshore),the module is a staple in emergency shutdown systems(ESD)for wellheads,pipelines,and processing facilities:an offshore platform in the North Sea installed 14 FM9925a-E modules to monitor 112 pressure/temperature sensors(analog inputs)and control 56 emergency valves(digital outputs).When a wellhead pressure exceeded 12,000 psi,the modules triggered valve closure within 10ms—preventing a blowout and avoiding$28M in environmental cleanup and production losses.The module’s ATEX Zone 2 certification also allows installation in hazardous areas,eliminating the need for expensive explosion-proof enclosures.

In chemical manufacturing,the FM9925a-E protects batch reactors and continuous processing lines:a specialty chemical plant uses the module to monitor 8 temperature sensors(analog inputs)and 6 pressure switches(digital inputs)on a polymerization reactor.If temperature exceeds 195℃or pressure exceeds 65 bar,the module activates 3 coolant valves(digital outputs)and shuts down the reactor feed pump—preventing overheating and potential explosions.The module’s SIL 3 rating ensures compliance with EU REACH and OSHA regulations,while its advanced diagnostics reduce unplanned downtime by 30%compared to the plant’s previous non-safety-certified modules.

Power generation facilities(coal,gas,nuclear)rely on the FM9925a-E for turbine and boiler safety:a 1,200MW gas-fired power plant uses the module to monitor turbine speed(analog inputs from speed transmitters)and boiler water level(analog inputs from level transmitters).If turbine speed exceeds 115%of rated RPM or water level drops below the minimum threshold,the module triggers an emergency trip(digital output)to shut down the turbine—avoiding catastrophic damage.The module’s compatibility with ABB’s 800xA DCS also enables seamless integration with the plant’s SCADA system,allowing operators to monitor safety loop status in real time and generate compliance reports automatically.

Pharmaceutical manufacturers use the FM9925a-E to meet FDA cGMP standards:a generic drug manufacturer uses the module to monitor temperature(analog inputs)and pressure(analog inputs)in a tablet compression line,as well as safety interlocks on equipment doors(digital inputs).The module’s precise analog measurement(±0.08%of full scale)ensures process parameters stay within regulatory limits,while its diagnostics prevent batch contamination by alerting operators to faulty sensors.This setup has reduced batch rejection rates by 17%and simplified FDA audit preparation by providing detailed data logs of safety loop performance.

Related Products

ABB Advant OCS:Core control system that integrates with the FM9925a-E;provides centralized process monitoring,safety logic execution,and data management for industrial SIS.

ABB S800 I/O Controller:Compact safety controller optimized for the FM9925a-E;supports up to 12 FM9925a-E modules for small-to-medium SIS(e.g.,chemical reactor safety).

ABB FM9930a-E HIEE451117R0001:Analog-only safety I/O module;16 4-20mA inputs(vs.FM9925a-E’s 8)for applications requiring high-density analog monitoring(e.g.,LNG tank level sensing).

ABB FM9940a-E HIEE451118R0001:Digital-only safety I/O module;16 digital inputs/8 digital outputs(vs.FM9925a-E’s 8/4)for systems with high discrete signal needs(e.g.,E-Stop loops in automotive manufacturing).

ABB Industrial Ethernet Switch ES820:8-port managed switch for reliable communication between FM9925a-E modules and ABB controllers;supports real-time data transmission.

ABB HMI 800xA:Human-machine interface software that displays FM9925a-E safety loop status;allows operators to acknowledge alarms,view diagnostic data,and manually override outputs(with authorization).

ABB Power Supply PS400:Redundant 24V DC power unit optimized for FM9925a-E modules;provides stable power for safety loops in harsh industrial environments.

ABB Calibration Kit CK-FM9925:Precision calibration tool for the FM9925a-E;includes a 4-20mA signal generator and digital voltage tester to verify analog/digital channel accuracy annually.

Installation and Maintenance

Pre-installation preparation:Before installing the ABB FM9925a-E HIEE451116R0001,verify compatibility with the target ABB system(Advant OCS firmware≥V5.2,S800 I/O firmware≥V3.1)and ensure field devices(sensors,valves)match the module’s I/O specifications(e.g.,24V DC for digital inputs,4-20mA for analog inputs).Inspect the module for physical damage(e.g.,bent pins,cracked housing)and confirm accessories(rack-mount brackets,wiring labels,certification documents)are included.Install the module in an ABB-compatible 3U rack within a control cabinet,ensuring the rack is properly grounded(ground resistance≤4Ω)to prevent EMI interference.For hazardous area installation(ATEX Zone 2),confirm the control cabinet meets IP54 ingress protection(dust and water resistance)and use armored cables for wiring.

Wiring and configuration:Use shielded twisted-pair cables for analog inputs(minimum 22AWG)and route them separately from power cables(≥30cm separation)to minimize noise.For digital inputs,use 24AWG cables(maximum length:150m)and connect to safety devices with double-wiring(redundant paths)for critical loops.Digital outputs should use 18AWG cables(to handle 2A current)and include surge protectors(e.g.,ABB SP06)to prevent voltage spikes from damaging the module.Configure the FM9925a-E using ABB Control Builder M software:assign signal types to channels(e.g.,4-20mA for AI1,24V DC DI for DI1),set alarm thresholds(e.g.,10,000 psi for pressure input),and enable redundancy(1oo2/2oo3)if required.Test each channel with a precision calibrator(e.g.,Fluke 754)to verify accuracy before integrating with the live SIS.

Maintenance recommendations:Conduct monthly visual inspections of the FM9925a-E—check for loose wiring,dust buildup on cooling vents(clean with compressed air),and LED status(green=normal,red=fault,yellow=warning).Every 3 months,use Control Builder M to run a full diagnostic test:this verifies channel functionality,redundancy切换,and communication with the ABB system.Calibrate analog inputs annually using the ABB CK-FM9925 calibration kit to maintain±0.08%accuracy—uncalibrated analog channels can lead to false alarms or missed safety events(e.g.,a temperature sensor reading 1.5%low,failing to trigger a shutdown).

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!