Description

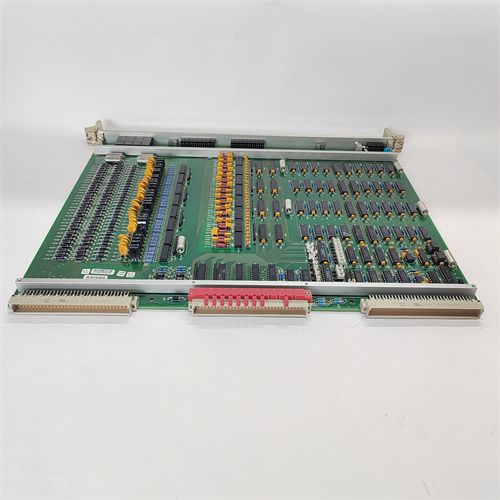

The ABB INICT03A is a legacy communication interface module developed for ABB’s MOD 300 and Advant distributed control system families. This board serves as a specialized network or fieldbus interface, enabling controllers and operator stations to communicate over specific industrial networks. It functions as a critical gateway, facilitating deterministic data exchange between different nodes within the control system architecture, ensuring synchronized operation and consistent data availability across the automation environment.

Application Scenarios

In a large chemical plant’s batch processing facility, reliable data exchange between the main process controllers and dedicated safety systems is paramount. The ABB INICT03A modules installed within the Advant Controller AC 450 racks serve as the dedicated communication channel for this purpose. One INICT03A might manage a high-integrity serial link to a dedicated safety PLC, continuously exchanging permissive and interlock signals. Another could interface with a proprietary motor control network. The module’s role is to provide a stable, deterministic, and isolated communication path for these critical but non-standard data flows. This isolates mission-critical traffic from the main operator network, ensuring that safety commands or drive controls are executed with minimal and predictable latency. Its failure would sever these vital links, potentially causing a process shutdown or loss of critical supervisory control, highlighting its function as a specialized communication nerve center.

Parameter

Technical Principles and Innovative Values

The ABB INICT03A represents a modular approach to system integration common in its era, allowing complex control systems to connect to diverse industrial networks.

Innovation Point 1: Protocol-Specific Hardware Offloading. The INICT03A was designed to handle the complete protocol stack of a specific network in dedicated hardware. This offloaded the complex, time-critical tasks of message framing, error checking, and media access control from the controller’s main CPU. This ensured that communication with specialized devices (like drives, weigh scales, or remote I/O) was both reliable and did not impact the controller’s primary scan time, maintaining deterministic control performance.

Innovation Point 2: Modular and Scalable System Architecture. By making network connectivity a plug-in module, the Advant system architecture gained significant flexibility. Engineers could select the specific INICT03A (or similar) interface required for a given application—be it a serial link, a sensor bus, or a peer-to-peer controller link—without changing the base controller hardware. This allowed for cost-effective customization and simplified system expansion.

Innovation Point 3: Deterministic and Robust Communication. The module was engineered for industrial environments, featuring electrical isolation, noise-immune transceivers, and robust connectors. For its target network, it provided deterministic data exchange, meaning data delivery times were bounded and predictable. This was crucial for applications like high-speed synchronization or safety interlocking, where random network delays were unacceptable.

Application Cases and Industry Value

Case Study: Steel Mill Finishing Line, Germany. A hot-dip galvanizing line used an ABB Advant system for process control. A critical requirement was high-speed, synchronized control of multiple sectional drives to maintain strip tension. This was achieved via a dedicated, high-speed serial network managed by INICT03A modules in each drive controller and the main Advant controller. The modules ensured microsecond-level synchronization of speed references. When one INICT03A in a legacy drive controller failed, it caused timing jitter, leading to strip flutter and product defects. Sourcing a refurbished INICT03A allowed for a like-for-like replacement that restored perfect synchronization without modifying any control logic, avoiding weeks of production downtime and potential system re-engineering. The module’s value was in preserving a complex, finely-tuned integration.

Case Study: Legacy Packaging Line Support, Food & Beverage. A high-speed bottling line from the late 1990s used an ABB Advant controller to manage conveyors and fillers, communicating with dozens of distributed servo drives via a now-obsolete sensor-actuator bus. The INICT03A module in the AC 450 controller was the master of this bus. When the module showed signs of intermittent failure, the plant faced a major dilemma: replace the entire control system at great cost and disruption, or find a spare. By procuring a tested INICT03A, they performed a direct swap during a scheduled maintenance weekend. The line was back in operation on Monday with zero changes to the proven application software, demonstrating the immense value of legacy component support in preserving capital investment and operational knowledge.

Related Product Combination Solutions

The ABB INICT03A was one of several communication options within the MOD 300/Advant ecosystem. Key related components include:

Advant Controller AC 450 / AC 410: The main process controller chassis into which the INICT03A module would be installed, providing the computational power and backplane connection.

Other Communication Modules (e.g., IMCIS02. IMMFP01): Different modules that handled other network types (e.g., the main OCS network, MB300). A controller could host multiple different communication modules simultaneously.

S800 I/O or other Remote I/O: The field devices that might be connected via the network served by the INICT03A, such as remote digital/analog I/O stations.

Specialized Field Devices: The third-party devices (servo drives, weigh scales, bar code readers) that used the specific protocol of the INICT03A for integration.

Operator Station (OCS): While the OCS typically used other modules (like IMMFP01) to talk to controllers, the INICT03A might be used in the OCS to connect to specialized sub-systems.

System Engineering Station: The software tool used to configure the controller, which also included configuration options for the INICT03A module’s network parameters and data exchange tables.

Installation, Maintenance, and Full-Cycle Support

Installation of the ABB INICT03A requires system power-down and ESD precautions. The module is inserted into a free slot in the Advant controller or station unit, securely fastened, and connected to its external network cable via the front or side connector. Configuration is performed using the MOD 300/Advant system engineering software, where the module type is selected, its hardware address is set (often via DIP switches on the board), and the data exchange between the controller’s memory and the network is mapped. This configuration is then downloaded to the controller.

Routine maintenance involves monitoring the module’s status LEDs for normal activity (power, network traffic) and ensuring the connected network cabling is secure. Diagnostics are primarily available through the system’s engineering or diagnostic software, which can report module health and communication errors. In the event of a suspected fault, swapping with a known-good module is a common diagnostic step. We provide comprehensive lifecycle support for such legacy components. This includes supplying fully refurbished and tested INICT03A modules, configuration backup/restore assistance, and technical guidance for troubleshooting and replacement procedures to minimize your system’s downtime and risk.