Description

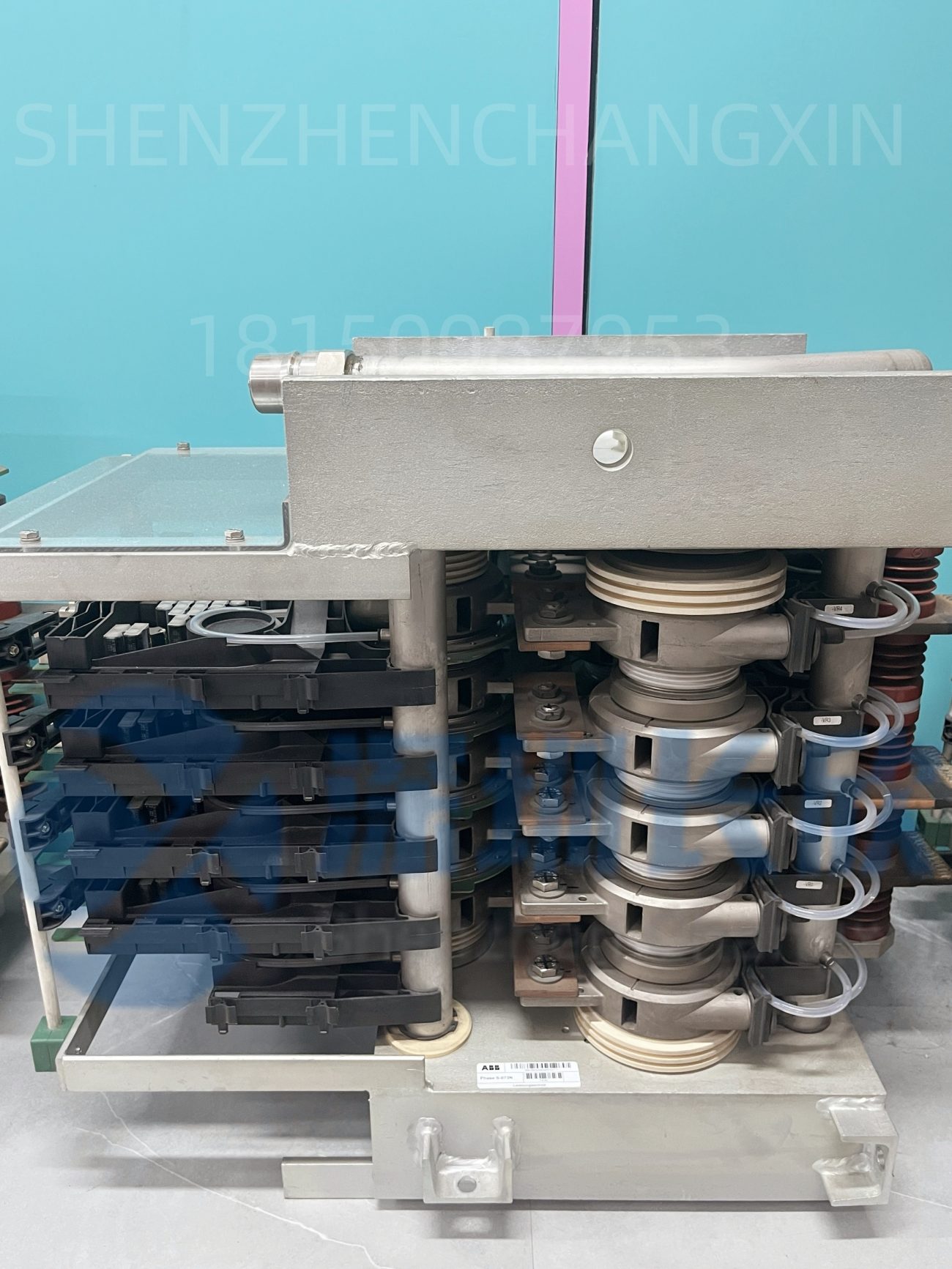

The ABB LXN1604-6 (also referenced by its internal manufacturing code 3BHL000986P7000) is a modular I/O base unit designed for ABB’s AC 800M controller platform within the System 800xA distributed control system (DCS). It serves as the mechanical and electrical foundation for plugging in compatible digital or analog I/O modules—providing secure field wiring terminals, backplane communication, and power distribution. The ABB LXN1604-6 / 3BHL000986P7000 enables rapid, error-resistant installation and supports hot-swappable module replacement, making it essential for high-availability process industries such as oil & gas, chemicals, and power generation.

Application Scenarios

At a European petrochemical plant undergoing a DCS modernization, engineers needed to minimize downtime during the migration from legacy Bailey INFI 90 to ABB System 800xA. By deploying pre-wired cabinets with ABB LXN1604-6 / 3BHL000986P7000 base units, they reduced field termination errors by 70% and cut commissioning time by three weeks. During a critical reactor temperature excursion six months later, a technician replaced a failed analog input module in under four minutes—without shutting down the process—thanks to the secure, keyed design of the ABB LXN1604-6 / 3BHL000986P7000. In this high-stakes environment, the base unit wasn’t just hardware—it was the backbone of operational agility.

Technical Principles and Innovative Values

Innovation Point 1: Tool-Free, Vibration-Resistant Spring-Clamp Terminals

The ABB LXN1604-6 / 3BHL000986P7000 supports push-in spring-clamp wiring—eliminating screws that can loosen in high-vibration environments like compressors or turbines—while maintaining >100 N pull-out force.

Innovation Point 2: Module-Specific Mechanical Coding

Each base features physical keying that only accepts its designated I/O module type (e.g., analog vs. digital), preventing costly misinsertion during maintenance—a common cause of spurious trips.

Innovation Point 3: Integrated Bus Connection with Zero Insertion Force (ZIF)

The backplane connector uses gold-plated contacts and guided alignment, ensuring reliable data/power transfer even after hundreds of hot-swap cycles.

Innovation Point 4: Panel Density Optimization

At just 16 mm wide, the ABB LXN1604-6 / 3BHL000986P7000 allows up to 62 I/O channels per 1-meter DIN rail when paired with 16-channel modules—reducing cabinet size and cost.

Application Cases and Industry Value

In a Middle Eastern LNG train, ambient temperatures regularly exceed 50°C, causing terminal oxidation and signal drift in older I/O bases. After upgrading to ABB LXN1604-6 / 3BHL000986P7000 units with tin-plated spring terminals, maintenance calls related to “noisy” 4–20 mA signals dropped by 88% over 18 months. Additionally, the ability to replace faulty modules during live operation avoided an estimated 120 hours of production loss annually. Plant automation leads now specify the ABB LXN1604-6 / 3BHL000986P7000 as standard for all new skid packages.

Related Product Combination Solutions

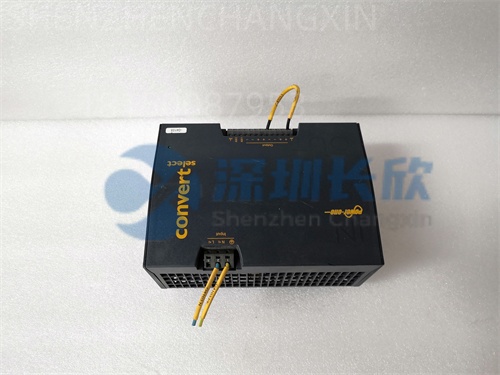

ABB AI810: 8-channel analog input module—plugs directly into the ABB LXN1604-6 / 3BHL000986P7000 for 4–20 mA signals.

ABB DI810: 16-channel digital input card—used with the ABB LXN1604-6 for valve feedback and alarm monitoring.

ABB CI854: Profibus DP communication module—connects S800 I/O (including LXN1604-6) to AC 800M controllers.

ABB AC 800M PM864: Main CPU—communicates with I/O via the LXN1604-6’s backplane bus.

ABB TK801V001: Configuration cable—used during initial setup of I/O modules on the LXN1604-6 base.

ABB 3BSE018144R1: Blank filler module—maintains IP rating when a slot is unused on the LXN1604-6.

ABB System 800xA Engineering: Software suite—auto-detects I/O topology including LXN1604-6 positions for streamlined configuration.

Installation, Maintenance, and Full-Cycle Support

Installing the ABB LXN1604-6 / 3BHL000986P7000 involves snapping it onto a standard 35 mm DIN rail, connecting shielded field wires to its terminals (with optional ferrules), and plugging in the compatible S800 I/O module until it clicks. No tools are needed for module replacement—simply lift the retention lever, swap the unit, and reseat. The base’s robust polycarbonate housing resists solvents, UV exposure, and thermal cycling.

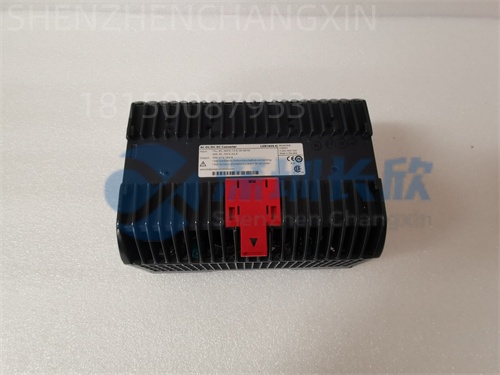

Maintenance requires only periodic visual inspection for terminal corrosion or loose strands. Because the ABB LXN1604-6 / 3BHL000986P7000 contains no active electronics, it rarely fails—but if damaged, replacement is fast and low-cost. Our stocked units are:

Verified for mechanical integrity (retention force, keying accuracy)

Tested with multiple I/O module types (AI, DI, DO)

Cleaned and inspected for terminal oxidation

Packaged with anti-static protection for ESD-sensitive environments

We provide technical guidance for panel layout optimization, wiring best practices, and compatibility checks across ABB System 800xA revisions.

Contact us for a customized solution—including bulk pricing for greenfield projects, obsolescence planning for legacy systems, or rapid delivery of certified ABB LXN1604-6 / 3BHL000986P7000 I/O bases to keep your automation infrastructure modular, maintainable, and future-ready.

fznor