Description

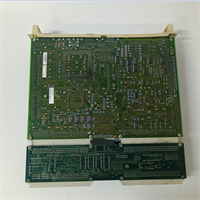

The ABB PFSK164 3BSE021180R1is a PROFIBUS DP communication interface module manufactured by ABB,designed for the S800 I/O system.This module acts as a versatile gateway,seamlessly bridging ABB’s distributed I/O with the widely adopted PROFIBUS DP fieldbus network.It enables high-speed,deterministic data exchange between master controllers and remote field devices in an industrial automation system.

Application Scenarios

In a large water treatment plant,the control system needs to gather data from hundreds of remote instruments—like flow meters,valve positioners,and pump status sensors—spread across vast distances.Hardwiring each device back to the central PLC is costly,complex,and difficult to maintain.The ABB PFSK164 3BSE021180R1solves this by acting as a PROFIBUS DP slave node.Installed in a remote cabinet with S800 I/O cards,it collects data from all local field devices and transmits it efficiently over a single,twisted-pair PROFIBUS cable to the central controller.This architecture drastically reduces wiring,installation time,and future maintenance costs,while providing a robust and reliable data highway for critical process control.

Parameter

Main Parameters

Value/Description

Product Model

ABB PFSK164 3BSE021180R1

Manufacturer

ABB Ltd.

Product Category

PROFIBUS DP Communication Interface Module

Parent System

ABB S800 I/O,System 800xA

Fieldbus Protocol

PROFIBUS DP(DP-V1)

Operating Mode

Slave

Data Transfer Rate

9.6 kbps to 12 Mbps(auto-sensing)

Electrical Interface

RS-485,isolated

Module Mounting

S800 Station,plugs directly onto the internal bus

Number of Connections

1 PROFIBUS DP port

Diagnostic Capabilities

Comprehensive module and channel status

Power Supply

24 VDC(via S800 baseplate)

Key Function

Connects S800 I/O to PROFIBUS DP networks

Technical Principles and Innovative Values

The ABB PFSK164 3BSE021180R1is more than a simple protocol converter;it is an intelligent integration point designed for system-level performance.

Innovation Point 1:Seamless S800 I/O Integration.The module plugs directly into the S800 station’s high-speed internal bus,ensuring deterministic data transfer between the PROFIBUS network and the connected I/O modules(e.g.,ABB AI810analog input or ABB DO810digital output modules).This tight integration eliminates bottlenecks and provides a cohesive,high-performance I/O subsystem.

Innovation Point 2:Advanced Diagnostics and Configuration.The ABB PFSK164 3BSE021180R1provides extensive diagnostic information accessible via the PROFIBUS master and ABB’s control software.This allows engineers to pinpoint issues remotely,whether it’s a network fault,a module failure,or a problem with a specific connected field device,dramatically reducing mean-time-to-repair(MTTR).

Innovation Point 3:Robust Network Performance.With support for the full PROFIBUS DP baud rate range up to 12 Mbps and featuring galvanic isolation on the RS-485 interface,the module ensures stable and noise-immune communication in electrically harsh industrial environments.This robustness is critical for maintaining data integrity in applications like motor control centers and process skids.

Application Cases and Industry Value

Case 1:Pharmaceutical Batch Process Skid

A pharmaceutical equipment manufacturer needed to pre-assemble and test process skids at their factory before shipping them to a customer site.Each skid contained numerous valves,sensors,and actuators.By using the ABB PFSK164 3BSE021180R1as the communication hub on each skid,they created a”plug-and-produce”system.On-site,engineers simply daisy-chained the PROFIBUS cable from skid to skid and connected it to the main DCS.This reduced on-site commissioning time by over 60%and eliminated wiring mistakes,ensuring a faster and more reliable project startup.

Case 2:Automotive Manufacturing Paint Shop

In an automotive paint shop,numerous pneumatic actuators control the movement of car bodies through the painting process.A centralized control system using AC 800M PLCs needed reliable I/O from these remote zones.The ABB PFSK164 3BSE021180R1modules,deployed in distributed cabinets,collected data from digital and analog modules monitoring the actuators.The reliability of the PFSK164in this high-electrical-noise environment ensured zero communication-related production stops,which was critical for maintaining the high-throughput,automated production line.

Related Product Combination Solutions

ABB SD821:The power supply module for the S800 station,providing stable 24VDC power to the ABB PFSK164 3BSE021180R1and all other I/O modules in the rack.

ABB AI810 3BSE008516R1:An 8-channel analog input module that connects field sensors(e.g.,4-20mA)to the S800 bus,with its data being communicated by the PFSK164.

ABB DO810 3BSE008513R1:A 16-channel digital output module for controlling actuators and solenoid valves,commanded via the PROFIBUS network through the PFSK164.

ABB TU847 3BSE013240R1:A communication interface for other protocols like Modbus TCP,offering an alternative network gateway within the same S800 family.

ABB CI854A 3BSE030220R1:A PROFIBUS DP master module for AC 800M controllers,which would be the master device communicating with the slave PFSK164modules in a network.

ABB SA801 3BSE052352R1:An S800 I/O station baseplate,which is the physical backbone that houses and interconnects the PFSK164and other I/O modules.

Installation,Maintenance,and Full-Cycle Support

Installing the ABB PFSK164 3BSE021180R1is a straightforward process.The module is simply plugged into a free slot in the SA801 or similar S800 I/O station baseplate,where it automatically connects to the internal power and communication bus.No internal wiring is required.The PROFIBUS network is then connected to the front-facing terminal connector,and the station address is set via the rotary switches on the module’s faceplate.

Maintenance for the ABB PFSK164 3BHE021000R0001is primarily proactive.Its built-in diagnostics provide continuous health monitoring,alerting operators to issues like network loss or configuration errors.Routine tasks are limited to ensuring the communication connectors are secure and the station is kept clean and within its specified operating temperature range.If a module fails,it can be hot-swapped in most redundant system configurations,allowing for replacement without shutting down the entire process.

We provide comprehensive full-cycle support for the ABB PFSK164 3BSE021180R1,from initial system design and configuration assistance to after-sales technical support.Our commitment includes providing genuine,factory-tested modules,access to firmware updates,and detailed documentation.Our global logistics network ensures you receive the critical components you need to minimize downtime and maintain operational continuity.

Contact us for a customized solution and to ensure seamless integration of the ABB PFSK164into your PROFIBUS DP network.

BENTLEY、TRICONEX、Woodward、FOXBORO、WESTINGHOUSE、Schneider、ABB、Motorola、GE、YOKOGAWA、HIMA、EMERSON

.jpg)