Description

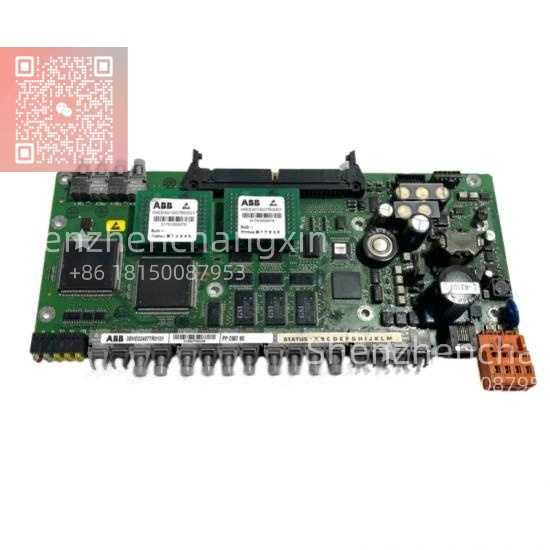

The PM866K02 is a high-performance, redundant-capable central processing unit (CPU) module from ABB’s AC 800M controller family, engineered for demanding applications within the System 800xA distributed control architecture. Featuring dual-core processing, enhanced memory capacity, and native support for real-time communication protocols, the PM866K02 delivers deterministic control, seamless redundancy, and robust cybersecurity—making it ideal for safety-critical and continuous-operation industries.

As the “brain” of modern ABB automation systems, the PM866K02 combines industrial-grade reliability with advanced computing power to manage thousands of I/O points, complex sequences, and enterprise-level data integration—all in a compact, DIN-rail-mountable form factor.

Application Scenarios

At a major LNG export terminal in Qatar, unplanned shutdowns could cost over $ 1 million per hour. To ensure uninterrupted liquefaction, engineers deployed dual ABB PM866K02 controllers in hot-standby redundancy across all critical process units. During a scheduled firmware update on the primary CPU, the system automatically transferred control to the backup unit in under 20 milliseconds—completely transparent to operators and field devices. “Zero process disturbance,” confirmed the site automation lead. “The PM866K02 didn’t just meet our availability target—it redefined it.” This case exemplifies how the PM866K02 transforms operational resilience in high-stakes environments where failure is not an option.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: True Synchronous Redundancy – The PM866K02 uses a dedicated fiber-optic link to mirror program execution, I/O states, and internal variables in real time between primary and backup units—ensuring zero data loss during failover, even mid-scan cycle.

Innovation Point 2: Enterprise-Grade Cybersecurity – Integrated firewall, secure boot, role-based access, and OPC UA encryption make the PM866K02 compliant with IEC 62443. protecting against evolving OT threats without external appliances.

Innovation Point 3: Unified Engineering & Runtime – Developed in ABB’s Control Builder M, the PM866K02 supports structured text, function blocks, and sequential function charts—enabling reuse of code across projects and seamless integration with 800xA HMI, asset optimization, and historian layers.

Innovation Point 4: Long-Term Investment Protection – With a projected lifecycle beyond 2035 and backward compatibility with earlier AC 800M modules, the PM866K02 safeguards capital expenditure in brownfield expansions and greenfield builds alike.

Application Cases and Industry Value

In a Scandinavian district heating network serving 500.000 residents, winter outages are unacceptable. The utility replaced aging controllers with redundant PM866K02 pairs at 12 pumping stations. During a cyber incident that disrupted communications at one site, the PM866K02’s built-in security features contained the breach while maintaining local control—keeping heat flowing. Operators also leveraged its OPC UA server to stream real-time efficiency data to a cloud analytics platform, reducing energy consumption by 7%. Similarly, in a U.S. biopharma facility, the PM866K02 manages sterile filling lines with full electronic batch records and 21 CFR Part 11 compliance—its deterministic scan times ensure precise timing for valve sequencing and temperature ramps, directly impacting product quality.

Related Product Combination Solutions

TB850 / TB851: Redundant CPU baseplates – required for hot-standby PM866K02 configurations with optical sync.

CI854: PROFIBUS DP communication module – extends PM866K02 connectivity to legacy field devices.

S800 I/O Modules (e.g., AI810. DO810): Distributed I/O stations – managed by PM866K02 over optical or copper links.

TPC-1570H: Operator workstation – visualizes and interacts with processes controlled by the PM866K02.

SNAT 7780: Secure remote access gateway – enables encrypted engineering access to PM866K02 without compromising network integrity.

AC 800M Connect: Integration software – links PM866K02 data to MES and ERP systems via OPC UA.

TU845: Terminal base – supports field wiring for local I/O connected to PM866K02-based cabinets.

PM864A: Entry-level CPU – can coexist in the same 800xA system for non-critical subsystems, reducing total cost of ownership.

Installation, Maintenance, and Full-Cycle Support

The PM866K02 installs onto a TB850 (primary) and TB851 (backup) base pair mounted on DIN rail, with the optical synchronization cable connecting the two units. Power and I/O backplane connections are handled through the base—no field wiring to the CPU itself. Commissioning is streamlined via Control Builder M, which auto-detects redundancy status and validates sync health. Routine maintenance involves periodic firmware updates (performed online on the standby unit first) and backup of application projects.

We supply only genuine, factory-sealed PM866K02 units (3BSE050190R5002), each verified for hardware authenticity and performance. Every controller undergoes functional testing—including redundancy switchover validation and communication stress tests—before dispatch. Backed by a 12-month warranty and supported by ABB-certified engineers, our PM866K02 solutions include startup assistance, lifecycle planning, and global logistics.

Contact us for a customized solution—whether you’re designing a new DCS, upgrading legacy Bailey INFI 90 systems, or securing spares for critical infrastructure, the PM866K02 delivers unmatched performance, availability, and future readiness for the world’s most demanding automation challenges.