Description

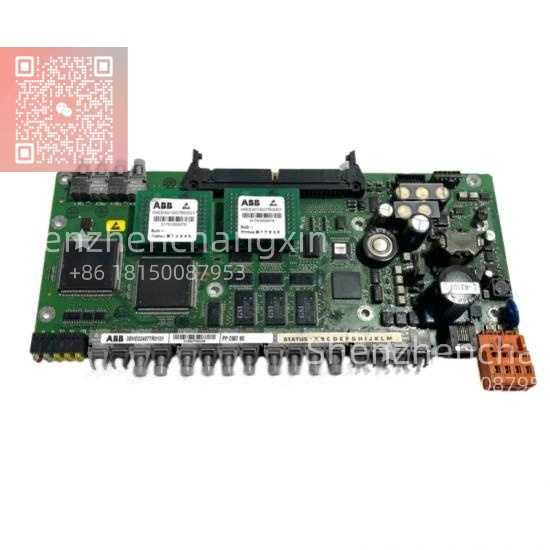

The PP15012HS-5A is a high-speed, 12-channel digital output (DO) module from ABB’s AC 500 I/O portfolio, engineered for fast and reliable control of 24 VDC loads such as solenoids, relays, indicator lights, and small actuators. Designed for seamless integration with AC 500. AC 500-S, and AC 500-Eco programmable logic controllers, the PP15012HS-5A combines high channel density, robust protection features, and microsecond-level response times—making it ideal for dynamic applications in packaging, assembly automation, and material handling.

Application Scenarios

At an automotive parts stamping plant in Mexico, a high-speed transfer line suffered from inconsistent part ejection due to slow relay-based outputs causing timing drift at 30 cycles/minute. Engineers replaced legacy relays with the PP15012HS-5A, leveraging its 10 µs switching speed and solid-state design. The module triggered pneumatic ejectors with sub-millisecond precision, synchronized perfectly with press position feedback. Over six months, misaligned parts dropped by 92%, and maintenance costs fell by $ 85.000 annually—thanks to zero contact wear. “The PP15012HS-5A didn’t just fix our timing—it eliminated a chronic quality leak,” said the lead automation engineer.

Parameter

表格

Technical Principles and Innovative Values

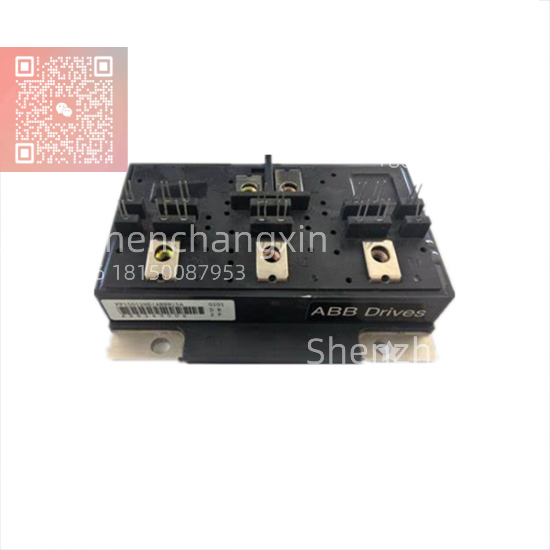

Innovation Point 1: Microsecond-Level Solid-State Switching – Unlike electromechanical relays or slower transistor modules, the PP15012HS-5A uses high-speed MOSFET drivers that enable precise pulse-width modulation (PWM) and rapid sequencing—critical for servo enable signals or high-cycle valve control.

Innovation Point 2: Intelligent Overload Management – Each output group on the PP15012HS-5A features electronic current limiting that clamps during short circuits and automatically resets when the fault clears—eliminating fuse replacements and unplanned downtime.

Innovation Point 3: True Plug-and-Play with AC 500 Ecosystem – The module draws power and communicates via the AC 500 local bus, requiring no external power supply or configuration jumpers. It is auto-detected in Automation Builder, reducing engineering time.

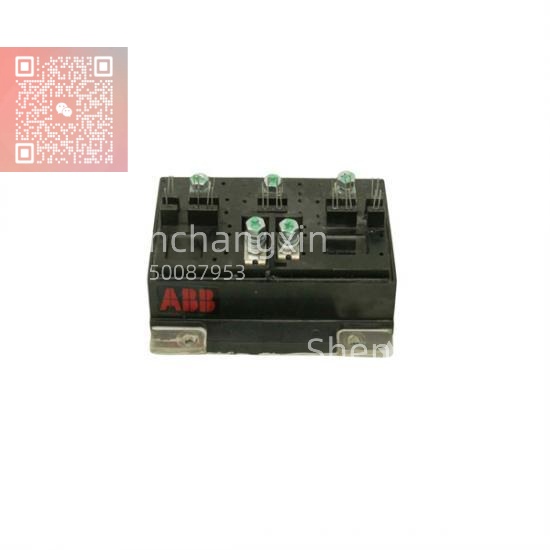

Innovation Point 4: Visual + Software Diagnostics Synergy – Front-panel LEDs provide instant field verification, while real-time status (e.g., “overload on Ch 5”) is reported to the PLC program—enabling predictive maintenance and smarter alarm logic.

Application Cases and Industry Value

A snack food packaging line in Poland upgraded from mechanical timers to an AC 500-based control system using PP15012HS-5A modules to drive 24 VDC bag-sealing solenoids. At 120 bags/minute, timing jitter from older DO cards caused seal leaks. The PP15012HS-5A’s consistent 8 µs turn-on delay ensured every seal was activated at the exact conveyor position. Reject rates fell from 3.1% to 0.2%, saving over €200.000 in wasted product annually. Additionally, the module’s compact size allowed the OEM to reduce panel footprint by 30%, lowering shipping and enclosure costs.

Related Product Combination Solutions

AC500-S CPU (e.g., PM573-ETH): High-performance controller – pairs seamlessly with PP15012HS-5A for fast scan applications.

PP15012H-5A: Standard-speed variant – use when ultra-fast switching isn’t required; PP15012HS-5A is optimized for high-frequency loads.

PP15008HS-5A: 8-channel version – offers same performance in smaller I/O count scenarios.

TB521: Terminal base with spring-cage wiring – provides secure, tool-free connections for PP15012HS-5A field outputs.

Automation Builder: ABB’s engineering platform – enables drag-and-drop configuration, diagnostics, and firmware management for PP15012HS-5A.

CPX500 HMI: Touchscreen operator interface – displays real-time DO status from PP15012HS-5A for troubleshooting.

PM5650-2ETH: Dual-Ethernet communication module – transports PP15012HS-5A status data to SCADA or cloud platforms.

ABB Ability™ Edge Analytics: Uses output cycle counts and fault logs from PP15012HS-5A to predict solenoid or valve end-of-life.

Installation, Maintenance, and Full-Cycle Support

Installing the PP15012HS-5A requires mounting it on the same DIN rail as an AC 500 CPU or local I/O station, ensuring full engagement with the backplane connector. Field wiring connects via compatible terminal bases (TB521 recommended) using stranded wires with ferrules. No external power is needed—the module is powered through the AC 500 bus. Configure output tags in Automation Builder; the system auto-assigns addresses.

Maintenance is proactive and efficient: inspect front-panel LEDs during routine rounds to confirm output activity, and monitor diagnostic bits in the PLC logic for early signs of overload or wiring degradation. In case of failure, the PP15012HS-5A can be hot-swapped without powering down the entire rack—minimizing production impact. We provide factory-tested units with full functional validation, 24-month warranty, and long-term availability commitment for brownfield and greenfield projects alike.

Contact us for a customized solution—whether you’re designing a new high-speed machine, replacing aging relay panels, or demanding industrial-grade reliability in compact form, the ABB PP15012HS-5A delivers precision, resilience, and intelligence where every microsecond—and every milliamp—counts.