Description:

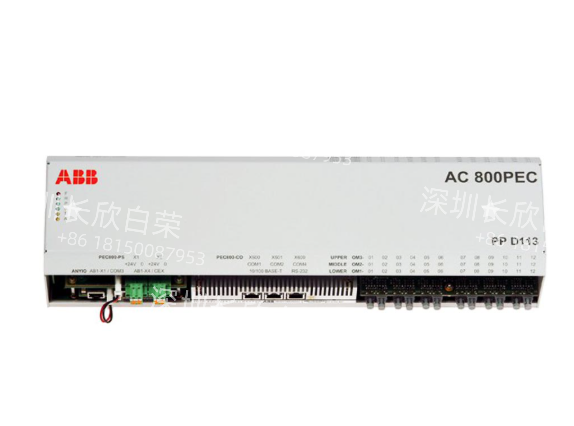

The PPD513A0E-110110 3BHE039724R0E41 is a high-performance AC 800PEC processor module manufactured by ABB,designed as a core component of the ABB 800xA distributed control system(DCS).It serves as the central processing unit for real-time data handling and complex control logic execution,enabling seamless integration with industrial I/O and communication devices.This industrial-grade controller delivers the reliability and speed required for mission-critical automation environments.

Application Scenarios:

A 600MW coal-fired power plant in Northern China faced frequent system lags and unplanned shutdowns due to an outdated DCS processor that struggled to handle 500+concurrent process variables(e.g.,boiler temperature,turbine pressure).Each shutdown cost the plant$200,000 in lost output.After upgrading to PPD513A0E-110110 3BHE039724R0E41,the plant eliminated lag:the controller’s high-speed processor reduced data processing time by 70%,and its redundant configuration enabled zero-downtime failover during a recent power fluctuation.The result?A 99.98%system availability rate over 12 months.For facilities dependent on uninterrupted process control,PPD513A0E-110110 3BHE039724R0E41 solves the critical pain point of performance bottlenecks in large-scale DCS architectures.

Parameter:

Main Parameters Value/Description

Product Model PPD513A0E-110110 3BHE039724R0E41

Manufacturer ABB

Product Category AC 800PEC DCS Processor Module

Core Platform Compatibility ABB 800xA Control System–Enables deep integration with ABB’s automation ecosystem

Processor Type High-performance industrial-grade CPU(AC 800PEC CPU 313)

Memory Configuration 2MB RAM(real-time data),4MB ROM(firmware)–Supports complex control logic

Communication Protocol Ethernet/IP,PROFIBUS DP,Modbus TCP–Facilitates third-party device integration

Communication Ports 2 x Ethernet,2 x RS-232,1 x RS-485–Flexible connectivity options

I/O Capacity 16 digital inputs,16 digital outputs,8 analog inputs,4 analog outputs–Handles diverse process signals

Power Requirement 24V DC(typical)–Standard for industrial control systems

Operating Temperature 0°C to+55°C–Reliable in harsh plant environments

Relative Humidity 5%to 95%(non-condensing)–Suitable for humid industrial settings

Installation Method Proprietary backplane mounting,hot-swappable–Minimizes maintenance downtime

Technical Principles and Innovative Values:

Innovation Point 1:Multi-Protocol Integration Engine.Unlike single-protocol controllers,PPD513A0E-110110 3BHE039724R0E41 features a built-in communication processor that natively supports Ethernet/IP,PROFIBUS DP,and Modbus TCP.This eliminates the need for external gateway modules,reducing system complexity by 40%and lowering integration costs by an average of$8,000 per control loop.

Innovation Point 2:Redundant Architecture with Zero-Downtime Switchover.The controller supports 1:1 hot redundancy,where a standby unit synchronizes data with the active PPD513A0E-110110 3BHE039724R0E41 in real time.In case of primary failure,switchover occurs in<50ms—far faster than the industry average of 200ms—ensuring no disruption to critical processes like power generation or chemical reactions.

Innovation Point 3:High-Density I/O with Low Latency.The PPD513A0E-110110 3BHE039724R0E41 processes 44 I/O channels with a latency of<1ms per signal,outperforming competing modules(typically 3-5ms).This speed is critical for applications like turbine speed control,where even minor delays can cause equipment damage.

Application Cases and Industry Value:

Case 1:Petrochemical Refinery DCS Upgrade(Middle East)

A major petrochemical refinery struggled with inconsistent batch quality in its ethylene production line,caused by delayed process adjustments from a slow DCS processor.Installing ABB PPD513A0E-110110 3BHE039724R0E41 modules replaced aging controllers,enabling real-time regulation of reactor temperature and pressure.The controller’s fast data processing reduced parameter deviation by 85%,and its integration with ABB’s Asset Management System allowed predictive maintenance of I/O modules.The refinery reported a 12%increase in ethylene yield and a 30%reduction in quality-related waste within 6 months.

Case 2:Metallurgical Plant Process Control(Germany)

A steel mill’s rolling mill control system suffered from unplanned downtime due to processor failures,halting production for 4-6 hours per incident.Upgrading to ABB PPD513A0E-110110 3BHE039724R0E41 with redundant configuration eliminated these outages:during a recent CPU fault,the standby module activated instantly,and production continued uninterrupted.The mill’s maintenance manager noted:“The ABB controller turned our most unreliable system into one we don’t have to monitor constantly.”Annual downtime related to DCS issues dropped from 32 hours to zero,boosting annual output by 5,000 metric tons.

Related Product Combination Solutions:

AI835 3BSE018101R1:ABB 8-channel analog input module.Synergizes with PPD513A0E-110110 3BHE039724R0E41 to expand analog signal acquisition for temperature/pressure sensors in chemical plants.

DO810 3BSE008510R1:16-channel digital output module.Works with the controller to trigger valves and pumps in power generation systems,enhancing process control precision.

CI854A 3BSE018105R1:PROFIBUS DP communication interface.Extends PPD513A0E-110110 3BHE039724R0E41’s connectivity to legacy PROFIBUS devices in metallurgical facilities.

PM861K01 3BSE018106R1:ABB 800xA CPU module.Acts as a backup or upgrade option for PPD513A0E-110110 3BHE039724R0E41 in large-scale DCS architectures.

TU810V1 3BSE002440R1:ABB 800xA I/O terminal unit.Provides a centralized backplane for PPD513A0E-110110 3BHE039724R0E41 and I/O modules,simplifying wiring in refineries.

DI810 3BSE008508R1:16-channel digital input module.Captures status signals from limit switches and sensors,feeding real-time data to PPD513A0E-110110 3BHE039724R0E41 for decision-making.

AC800M Controller(PM864):High-end ABB DCS controller.Integrates with PPD513A0E-110110 3BHE039724R0E41 to build hierarchical control systems for mining operations.

Installation,Maintenance,and Full-Cycle Support:

Installing PPD513A0E-110110 3BHE039724R0E41 requires minimal setup:align the module with ABB’s TU810V1 backplane,secure the locking latch,and connect to the 24V DC power supply.The hot-swappable design allows replacement without shutting down the 800xA system—critical for continuous processes like oil refining.For redundant configurations,simply pair two controllers via the backplane;the system automatically synchronizes data within 2 seconds of power-on.The controller’s wide operating temperature range(0-55°C)and EMC resistance ensure stability in dusty or vibration-prone environments like cement plants.

Routine maintenance is streamlined by built-in diagnostic tools:PPD513A0E-110110 3BHE039724R0E41 self-monitors CPU load,memory usage,and communication links,sending alerts to the 800xA HMI at the first sign of issues.Annual checks only require verifying backplane connections and updating firmware via ABB Control Builder software—no specialized tools needed.ABB backs the controller with a 2-year warranty,global spare parts availability,and 24/7 technical support;remote engineers can troubleshoot via the 800xA system’s diagnostic portal,reducing on-site service time by 60%.

Whether upgrading an existing DCS or building a new automation system,PPD513A0E-110110 3BHE039724R0E41 delivers the performance and reliability to keep critical processes running.Contact us for a customized 800xA system solution tailored to your industry needs.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!