Description

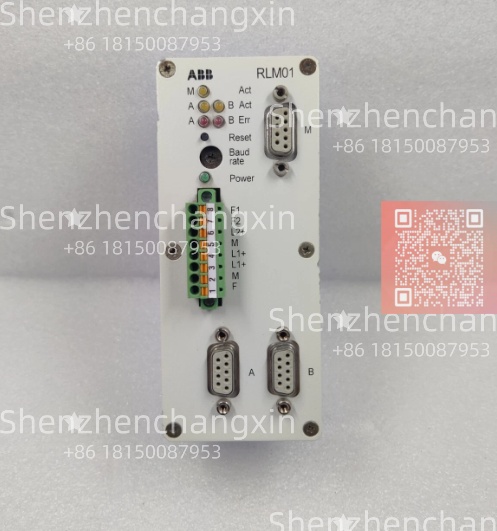

The ABB RLM01 3BDZ000398R1is a high-availability redundancy module designed for critical industrial automation systems requiring continuous operation without single points of failure.This advanced redundancy controller provides seamless switchover capability between primary and backup controllers,ensuring uninterrupted process operation in mission-critical applications.The ABB RLM01 3BDZ000398R1implements sophisticated synchronization and monitoring algorithms to maintain system integrity during normal operation and automatic failover scenarios,making it essential for applications where system downtime is not an option.

Application Scenarios

In a large petrochemical complex in Saudi Arabia,the ABB RLM01 3BDZ000398R1redundancy modules were deployed to control critical cracking unit operations where even momentary system failure could result in significant production losses and safety concerns.The facility previously experienced costly shutdowns due to controller failures until implementing the ABB RLM01 3BDZ000398R1system.The modules continuously monitored twin controllers,automatically switching to the backup unit within milliseconds when a fault was detected in the primary system.This implementation resulted in 99.999%system availability over three years of continuous operation,with several automatic failovers occurring transparently without process interruption.

Parameter

Main Parameters

Value/Description

Product Model

ABB RLM01 3BDZ000398R1

Manufacturer

ABB

Product Type

Redundancy Link Module

System Compatibility

AC 800M High Integrity Controllers

Redundancy Type

Hot standby with automatic switchover

Switchover Time

<100 milliseconds typical

Synchronization Method

Fiber optic or copper cable

Communication Ports

2 x redundancy synchronization ports

Data Synchronization Rate

100 Mbps full duplex

Monitoring Features

Continuous diagnostics and heartbeat monitoring

Power Supply

24V DC redundant input

Power Consumption

<15W typical

Operating Temperature

0°C to+60°C

Storage Temperature

-40°C to+85°C

Relative Humidity

5%to 95%non-condensing

Vibration Resistance

2g(5-150Hz)

Shock Resistance

15g for 11ms

MTBF

>250,000 hours

Certifications

SIL 3,CE,UL,cULus

Technical Principles and Innovative Values

Advanced Synchronization Technology:The ABB RLM01 3BDZ000398R1utilizes high-speed data synchronization technology that maintains identical memory states between primary and backup controllers.The module employs specialized algorithms that track all controller operations including process image updates,timer values,and data block changes.This sophisticated synchronization ensures that the backup controller can assume control instantly without data loss or process disruption.The ABB RLM01 3BDZ000398R1achieves this through dedicated fiber optic connections that provide electrical isolation and noise immunity while supporting high-speed data transfer rates up to 100 Mbps.

Intelligent Fault Detection and Diagnostics:Featuring comprehensive diagnostic capabilities,the ABB RLM01 3BDZ000398R1continuously monitors both controller health status,communication links,power supplies,and synchronization integrity.The module employs multiple watchdog mechanisms including heartbeat monitoring,memory checksum verification,and I/O consistency checking.When the ABB RLM01 3BDZ000398R1detects any abnormality in the primary controller,it initiates an automatic switchover procedure that transfers control to the backup unit within 100 milliseconds,ensuring continuous process operation.The module maintains detailed fault logs that assist in troubleshooting and preventive maintenance planning.

Robust Hardware Architecture:The ABB RLM01 3BDZ000398R1is built with industrial-grade components designed for 24/7 operation in harsh environments.The module features redundant power supply inputs with reverse polarity protection and wide input voltage range.The high-quality fiber optic interfaces provide galvanic isolation between controllers,preventing ground loop issues and ensuring immunity to electromagnetic interference.The compact design with efficient heat dissipation allows high-density installation in control cabinets while maintaining optimal operating temperatures.

Application Cases and Industry Value

In a nuclear power plant safety system in France,the ABB RLM01 3BDZ000398R1redundancy modules were implemented for reactor protection systems where maximum reliability was mandated by nuclear regulatory requirements.The system configuration involved triple modular redundancy with three independent control channels,each protected by ABB RLM01 3BDZ000398R1modules.During a scheduled maintenance test where a primary controller was intentionally failed,the ABB RLM01 3BDZ000398R1executed a flawless switchover to the backup controller with zero process impact.The system’s ability to maintain continuous operation during controller updates and hardware replacements significantly reduced maintenance windows and improved overall plant availability.The installation demonstrated compliance with IEC 61508 SIL 3 requirements,providing the highest level of safety integrity for nuclear applications.

Related Product Combination Solutions

ABB PM864AK01-AC 800M Processor for redundant configuration

ABB SD832-Digital input module for redundant systems

ABB TA810-Terminal unit for I/O mounting

ABB CI871-Communication interface module

ABB SA811-Analog input module

ABB SC81x-System communication modules

ABB PU51x-Power supply units

ABB CEX-Communication extension modules

Installation,Maintenance,and Full-Cycle Support

Installation Requirements:The ABB RLM01 3BDZ000398R1requires proper mounting in a well-ventilated control cabinet with adequate space for cable routing and heat dissipation.The redundancy fiber optic cables must be routed separately from power cables to prevent interference.Ensure proper grounding of both controllers and maintain equal cable lengths between primary and backup systems to maintain synchronization timing.The module should be installed in a controlled environment with stable temperature and humidity conditions.Follow ABB’s specific guidelines for redundant system configuration and commissioning procedures.

Maintenance Protocol:Regular maintenance of the ABB RLM01 3BDZ000398R1includes monitoring system status indicators,verifying synchronization status,and checking error logs for any abnormal events.Perform regular switchover tests during planned maintenance windows to verify proper failover functionality.Keep fiber optic connectors clean and inspect cables for damage.Maintain updated firmware versions and keep configuration backups for quick recovery.Monitor system performance metrics to identify potential issues before they impact system availability.

Technical Support Commitment:We provide comprehensive support for the ABB RLM01 3BDZ000398R1,including system design assistance,configuration services,and troubleshooting support.Our technical team offers 24/7 emergency support for critical systems and maintains a stock of spare modules for quick replacement.We provide detailed documentation and training for proper operation and maintenance of redundant systems.Contact us for customized redundancy solutions tailored to your specific availability requirements.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!