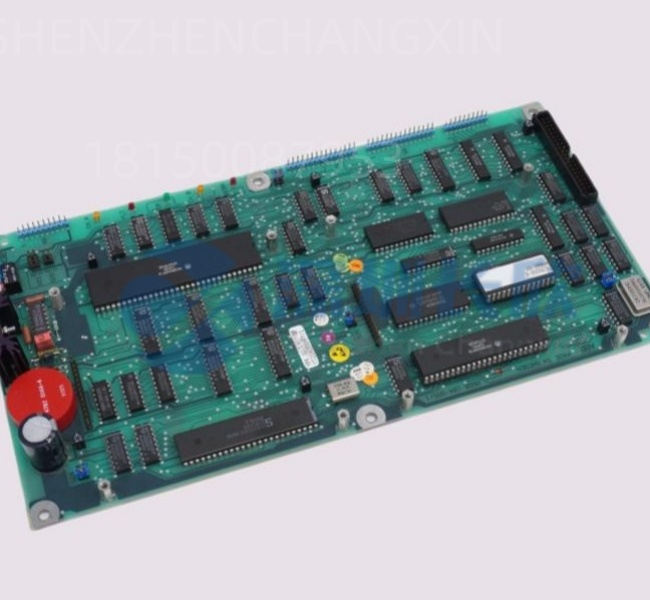

Description:

The ABB ZINT-541 (part number 3AUA00000658960) is a versatile, high-density digital input/output module designed for integration into ABB’s distributed control and automation systems. This module acts as a critical interface node, connecting a large number of field devices—such as sensors, switches, valves, and indicators—to the central control system, enabling precise monitoring and command execution for industrial processes.

Application Scenarios:

In a large water treatment facility, the coagulation and flocculation process relies on dozens of motorized valves, flow switches, and tank level sensors to operate automatically. Manually monitoring and controlling each device is impossible. Multiple ABB ZINT-541 (3AUA00000658960) modules are installed in distributed I/O cabinets near the process units. One module’s inputs are wired to all the high-level and low-level switches in a chemical dosing tank bank, while its outputs are connected to the solenoid valves controlling inlet flows. The module continuously scans the state of every level switch. When the control logic determines a tank is low, it commands the ABB ZINT-541 to energize the specific output channel for the correct feed valve. This localized, high-density I/O processing reduces miles of wiring back to a central room and provides fast, reliable control. The ABB ZINT-541 solves the key pain points of wiring complexity, signal latency, and maintenance accessibility, ensuring precise chemical dosing and preventing pump dry-run or tank overflow conditions.

Parameter:

Technical Principles and Innovative Values:

The ABB ZINT-541 (3AUA00000658960) is engineered for reliability and integration in distributed architectures:

Innovation Point 1: High-Density, Configurable I/O Design. The module maximizes space efficiency by accommodating a high number of I/O points in a single unit. Its design often allows for flexible configuration of individual or groups of channels as inputs or outputs via software or hardware settings, providing exceptional adaptability to varying application needs without changing hardware.

Innovation Point 2: Advanced Diagnostics for Predictive Maintenance. The ABB ZINT-541 incorporates intelligent diagnostics that go beyond simple on/off status. It can detect field-side faults such as short circuits on outputs, open-wire conditions on inputs, and overloads. These diagnostics are reported to the central controller, enabling predictive maintenance alerts before a failure causes a process shutdown, significantly improving system availability.

Innovation Point 3: Seamless Integration into ABB’s System Architecture. The module is not a standalone device but a fully integrated component of ABB’s automation ecosystem. It communicates seamlessly over ABB’s high-speed control network, ensuring deterministic data exchange with the controller. This deep integration simplifies engineering, configuration via tools like Control Builder, and centralized monitoring.

Innovation Point 4: Ruggedized Construction for Industrial Environments. Built to withstand the harsh conditions of industrial plants, the ABB ZINT-541 features robust electrical isolation, protection against voltage transients, and a design for reliable operation across a wide temperature range. This ensures long-term stability in environments with significant electrical noise and temperature fluctuations.

Application Cases and Industry Value:

A pharmaceutical manufacturer with a batch process for sterile products faced challenges with manual valve sequencing, leading to occasional cross-contamination risks and batch record discrepancies. They automated the process using an ABB distributed control system with ABB ZINT-541 (3AUA00000658960) modules installed in local panels near the reactor vessels. Each module controlled dozens of pneumatic diaphragm valves and received signals from position sensors. The precise, automated sequencing eliminated human error. Furthermore, the diagnostic feature of the ABB ZINT-541 proved invaluable when it detected a degrading solenoid coil (showing as a falling current draw) on a critical vent valve weeks before it failed. Maintenance was scheduled during a planned washout, avoiding a potential batch loss worth over $500.000. The ABB ZINT-541 delivered value by enabling flawless automation for quality-critical processes and providing intelligent diagnostics that transitioned maintenance from reactive to predictive, ensuring both product quality and operational efficiency.

Related Product Combination Solutions:

ABB S800 I/O Base Units (e.g., TU845. TU847): The mounting units that house and provide communication for the ABB ZINT-541 modules in a distributed I/O station.

ABB CI854A / CI855A Communication Interfaces: These modules act as the network gateways, connecting the I/O station containing the ABB ZINT-541 to the main control network (e.g., PROFIBUS, Ethernet).

ABB Analog I/O Modules (e.g., AI845. AO845): Complementary modules used in the same I/O station for handling 4-20mA or temperature signals, alongside the digital ABB ZINT-541.

ABB AC 800M / AC 700F Controllers: The high-level process controllers that execute the logic and communicate with the I/O stations housing the ABB ZINT-541.

ABB Control Builder Professional: The engineering software used to configure, program, and diagnose the entire system, including all parameters for the ABB ZINT-541 modules.

ABB TA511 / TA521 Terminal Blocks: The field wiring connection units that interface the field device cables to the ABB ZINT-541 module’s internal electronics.

ABB SD821 / SD822 Digital Input/Output Modules: Other models in the S800 I/O family, offering different point densities or voltage ratings, used alongside the ABB ZINT-541.

Installation, Maintenance, and Full-Cycle Support:

Installation of the ABB ZINT-541 (3AUA00000658960) involves plugging it securely into its designated slot on the compatible ABB I/O base unit. The critical step is the proper termination of field wires to the corresponding terminal block unit, ensuring correct voltage levels and polarity. Configuration is performed using ABB’s Control Builder software, where the module type is recognized, and its channels are defined as inputs or outputs and mapped to process variables.

Routine maintenance is streamlined by the module’s diagnostic capabilities. Status is continuously monitored via the control system HMI. The LED indicators on the module provide immediate visual feedback on communication status, module health, and individual channel activity. In the event of a fault, diagnostics pinpoint the issue to a specific channel, allowing for rapid troubleshooting. The module is designed for hot-swapping in systems that support it, allowing replacement without a full system shutdown. We provide comprehensive support for the ABB ZINT-541. from supplying genuine modules and terminal accessories to offering technical guidance on configuration, integration, and troubleshooting within your ABB system architecture.