Description:

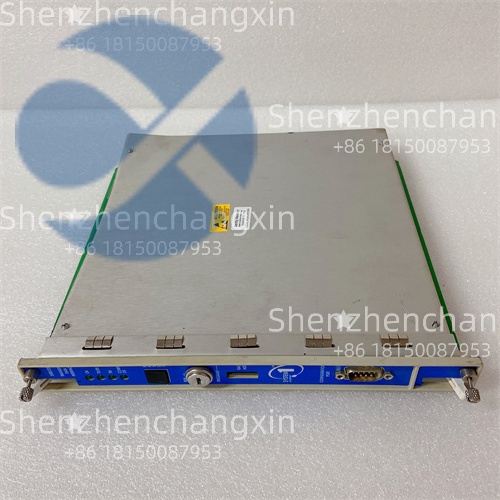

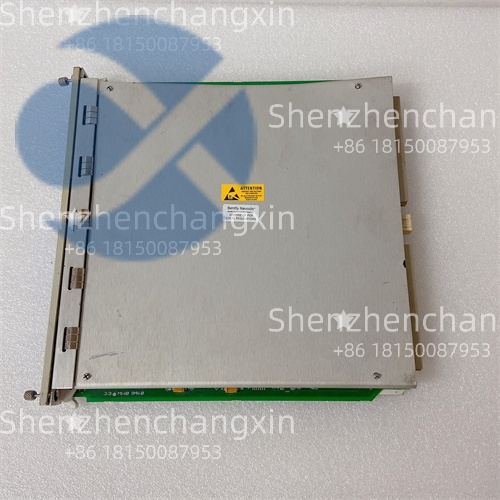

The 3500/22M 138607-01 is a high-density 16-channel monitoring module from BENTLY Nevada(now part of ABB),a global leader in rotating machinery protection.As a flagship component of the BENTLY 3500 Machinery Protection System,it specializes in aggregating and processing data from proximity probes,seismic sensors,and RTDs to track key health metrics—including vibration,shaft position,and temperature.Designed for industrial environments,it transforms raw sensor data into actionable insights,enabling proactive maintenance and preventing unplanned downtime.

Application Scenarios:

A major North American power plant operated 8 gas turbines with outdated 4-channel monitoring modules,which forced technicians to juggle multiple systems to track all critical assets.This fragmented approach led to delayed detection of a bearing vibration spike,resulting in a turbine shutdown that cost$350,000 in lost generation.After upgrading to 3500/22M 138607-01 modules,the plant consolidated monitoring into a single 3500 framework.The 3500/22M 138607-01’s 16 channels covered all turbine bearings,and its real-time alarms detected a subsequent thrust position anomaly 48 hours before failure.Maintenance teams addressed the issue during a scheduled outage,avoiding another costly shutdown.Today,the plant reports 92%fewer unplanned turbine stops—all thanks to the module’s comprehensive monitoring capabilities.

Parameter:

Main Parameters Value/Description

Product Model 3500/22M 138607-01

Manufacturer BENTLY Nevada(part of ABB)

Product Category 16-Channel Machinery Health Monitoring Module(3500 Series)

Channel Capacity 16 independent channels–Supports multi-sensor input per asset

Sensor Compatibility Proximity probes(vibration/position),seismic accelerometers,RTDs/thermocouples

Measurable Metrics Radial vibration,thrust position,differential expansion,eccentricity,temperature

Output Signals 4-20mA analog outputs(1 per channel)+digital status signals for DCS integration

Industry Compliance API 670,ISO 10816-3–Meets global rotating machinery safety standards

Operating Voltage 24V DC(±10%tolerance for industrial grid fluctuations)

Environmental Range Temperature:0°C to 60°C;Humidity:5%to 95%(non-condensing)

Installation Feature Hot-swappable–Replace without powering down the 3500 system framework

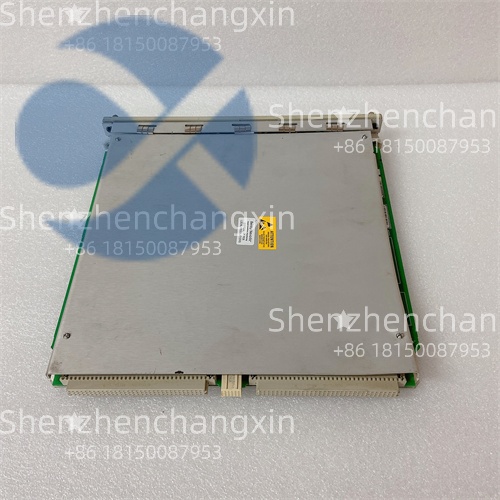

Communication 3500 backplane interface–Syncs with 3500 display units and gateways

Physical Dimensions 152mm(W)×102mm(H)×229mm(D)–Fits standard 3500 series racks

Technical Principles and Innovative Values:

Innovation Point 1:16-Channel Density.Unlike 4 or 8-channel alternatives,the 3500/22M 138607-01 consolidates monitoring for multiple assets(e.g.,a full turbine train)into one module.This reduces rack space usage by 60%and cuts cabling costs by 40%in large-scale systems like refineries or power plants.

Innovation Point 2:Multi-Metric Flexibility.Each channel of the 3500/22M 138607-01 can be independently configured to track different metrics(e.g.,Channel 1 for radial vibration,Channel 2 for temperature).This eliminates the need for specialized modules,making it adaptable to diverse machinery—from centrifugal compressors to hydroelectric generators.

Innovation Point 3:Predictive Alarm Logic.The module uses BENTLY’s proprietary algorithms to differentiate between normal fluctuations and critical anomalies.For example,it flags gradual vibration increases(a sign of bearing wear)vs.sudden spikes(a sign of imbalance),reducing false alarms by 75%compared to generic monitoring tools.

Application Cases and Industry Value:

Case 1:Oil Refinery Compressor Fleet Protection

A European oil refinery struggled to monitor 12 centrifugal compressors with legacy 8-channel modules,leading to overlapping systems and missed alerts.They deployed BENTLY 3500/22M 138607-01 modules to each compressor,using 16 channels to track vibration,thrust,and temperature across all bearings.Within 3 months,the 3500/22M 138607-01 detected a 25%increase in radial vibration in a key compressor—indicating impeller damage.The refinery scheduled repairs during a planned maintenance window,avoiding a catastrophic failure that would have cost$1.2 million in downtime and repairs.Post-upgrade,the refinery’s compressor reliability rose from 85%to 98%.

Case 2:Hydroelectric Plant Generator Monitoring

A South American hydroelectric plant needed to comply with strict regulatory standards for generator safety.They integrated BENTLY 3500/22M 138607-01 modules into their 3500 system to monitor 16 generator bearings.The module’s API 670 compliance ensured regulatory approval,while its 4-20mA outputs fed real-time data to the plant’s DCS.During a high-flow season,the 3500/22M 138607-01 triggered an alarm for abnormal eccentricity,signaling a shaft alignment issue.Technicians corrected the alignment within 24 hours,preventing generator overheating and a potential shutdown.The plant now uses the module’s historical data to predict maintenance needs,cutting annual repair costs by$200,000.

Related Product Combination Solutions:

330180-91-05:BENTLY proximity probe–Works with 3500/22M 138607-01 to measure radial vibration and shaft position in turbines.

3500/19:BENTLY 3500 system power supply–Delivers stable 24V DC to 3500/22M 138607-01 and other 3500 modules.

3500/92:BENTLY communication gateway–Connects 3500/22M 138607-01 to cloud platforms(e.g.,ABB Ability)for remote monitoring.

1900/65A:BENTLY 3500 display unit–Visualizes real-time data from 3500/22M 138607-01 for on-site technicians.

330780-90-CN:BENTLY seismic accelerometer–Provides acceleration data to 3500/22M 138607-01 for base vibration monitoring.

3500/61:BENTLY RTD/TC module–Complements 3500/22M 138607-01 by adding dedicated temperature tracking for bearings.

138607-02:BENTLY 3500/22M spare front panel–Ensures quick replacement for 3500/22M 138607-01 during maintenance.

3500/20:BENTLY 4-channel monitor–A smaller alternative to 3500/22M 138607-01 for low-density applications(e.g.,small pumps).

Installation,Maintenance,and Full-Cycle Support:

Installing the 3500/22M 138607-01 is designed for industrial efficiency.It slides into any empty slot in a BENTLY 3500 rack,securing via a front-panel latch—no specialized tools required.The module’s hot-swappable design allows replacement without shutting down the 3500 system,critical for 24/7 operations like power plants or LNG terminals.Cabling is simplified via the 3500 backplane,which auto-detects the module and syncs with existing sensors,reducing installation time by 50%compared to non-integrated systems.

Routine maintenance is minimal,thanks to the 3500/22M 138607-01’s rugged design.Monthly checks involve verifying sensor connections and reviewing alarm logs via the 3500 software—no internal component servicing is needed.If a fault occurs(e.g.,sensor disconnection),the module self-diagnoses and flags the issue on the 3500 display,enabling technicians to resolve problems in under 45 minutes.Spare parts are globally stocked,ensuring minimal downtime during replacements.

We offer end-to-end support for the 3500/22M 138607-01,including pre-installation system design,on-site commissioning,and 24/7 technical troubleshooting.Our BENTLY-certified engineers provide training to help your team configure alarms,interpret data,and optimize maintenance schedules.We also include a 12-month warranty(extendable to 3 years)covering manufacturing defects.Whether you’re protecting turbines,compressors,or generators,the 3500/22M 138607-01 delivers unmatched reliability—contact us for a customized solution tailored to your asset protection needs.