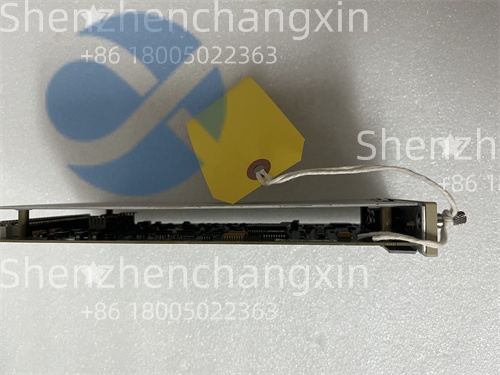

Product Overview

The BENTLY 3500/61 is a high-reliability 16-channel relay output module designed for the Bently Nevada 3500 Machinery Protection System,a globally recognized platform for continuous monitoring and safeguarding of critical rotating equipment.As a core component of the 3500 rack-based architecture,the BENTLY 3500/61 translates real-time alarm and trip conditions—generated by input modules such as the 3500/42(vibration)or 3500/45(position)—into discrete electrical actions via electromechanical relays.These actions typically drive external systems like emergency shutdown valves,motor starters,annunciators,or plant DCS interlocks,ensuring rapid and deterministic response to abnormal machine behavior.

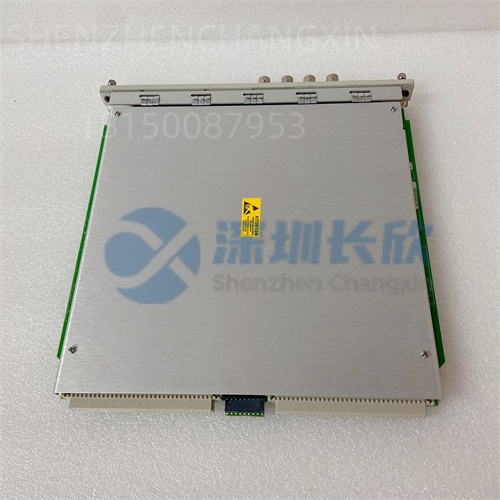

Engineered for mission-critical applications in power generation,oil&gas,and heavy industry,the BENTLY 3500/61 features Form C(SPDT)relays with galvanic isolation between channels and from the backplane,minimizing cross-talk and enhancing system integrity.Each relay is individually programmable through the 3500 Configuration Software,allowing users to assign specific alarm levels(e.g.,Alert,Danger,Shutdown)from any monitored channel to any physical output.The module includes front-panel LEDs for visual indication of relay coil status and fault conditions,supporting rapid diagnostics during commissioning or maintenance.Fully compatible with redundant 3500/62 or 3500/65 interface modules,the BENTLY 3500/61 can be deployed in both simplex and redundant configurations,making it suitable for applications requiring compliance with IEC 61508 up to SIL2 when implemented in a certified safety architecture.

Technical Specifications

Parameter Name Parameter Value

Product Model 3500/61

Manufacturer Bently Nevada(a Baker Hughes company)

Product Type Relay Output Module

Number of Channels 16 isolated relay outputs

Relay Type Form C(SPDT),electromechanical

Contact Rating 2 A 30 V DC;1 A 120 V AC(resistive load)

Isolation 500 VRMS channel-to-channel and channel-to-backplane

Operating Voltage Powered via 3500 system backplane(±12 V,+5 V)

Compatible Chassis 3500/15,3500/20,3500/22,3500/25

Hot-Swap Support Yes(in supported 3500 racks)

Indicators Dual LEDs per channel:Coil Status and Fault

Safety Certification Suitable for SIL2 applications per IEC 61508(system-dependent)

Operating Temperature 0°C to+65°C

Main Features and Advantages

Flexible alarm routing and logic integration:The 3500/61 allows each of its 16 relays to be independently mapped to any alarm condition from any input module in the 3500 rack.This enables complex trip logic—such as“OR”combinations of bearing vibration and shaft displacement—without external hardwiring.Changes are made entirely in software via the 3500 Configuration Tool,reducing engineering time and eliminating wiring errors.

Robust electromechanical reliability:Unlike solid-state outputs,the 3500/61 uses proven mechanical relays that provide true electrical isolation and can directly switch AC or DC loads up to 120 V.This eliminates the need for intermediate interposing relays in many applications,simplifying panel design and improving mean time between failures(MTBF).

Fail-safe and diagnostic transparency:In the event of a module fault or loss of backplane power,the 3500/61 relays de-energize to a safe state(user-configurable as normally open or closed).Front-panel LEDs clearly indicate coil activation and internal faults,while the 3500 system logs detailed status for remote access via Modbus or Ethernet interfaces.

Seamless redundancy support:When used with a 3500/62(Redundant Relay Module Interface)or 3500/65(TMR Voting Relay Module),the 3500/61 participates in redundant or voted output architectures,ensuring continued operation even if one relay path fails.This is essential for turbines,compressors,and other assets where unplanned trips carry severe operational or safety consequences.

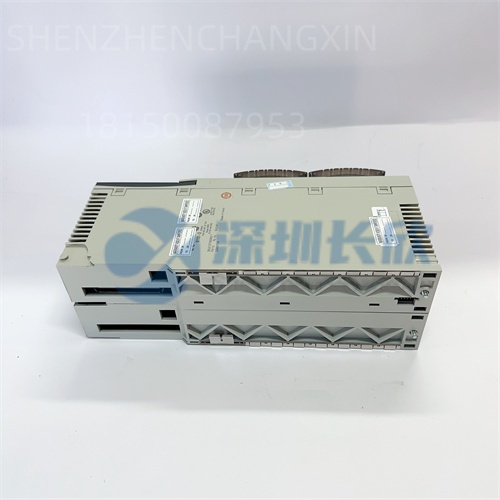

Compact high-density design:With 16 isolated outputs in a single-width 3500 module slot,the 3500/61 maximizes I/O density while maintaining serviceability.Its standardized form factor integrates effortlessly into existing 3500 racks,enabling easy expansion or replacement during upgrades.

Application Field

The 3500/61 is indispensable in facilities where machinery failure could result in safety incidents,environmental releases,or multi-million-dollar downtime.In combined-cycle power plants,it executes turbine overspeed trips,bearing temperature shutdowns,and lube oil pressure interlocks—directly actuating hydraulic stop valves or generator breakers.Its ability to deliver fail-safe,high-integrity outputs ensures compliance with API 670 standards for machinery protection.

In oil&gas upstream and midstream operations,the 3500/61 safeguards centrifugal compressors on gas pipelines and refrigeration units in LNG trains.For example,if axial displacement exceeds safe limits,the 3500/61 triggers a shutdown sequence that isolates the compressor and vents pressure—preventing catastrophic rotor contact.Similarly,in refinery hydrocracker recycle gas compressors,it interfaces with the plant ESD system to halt feed pumps upon vibration alarms.

Heavy industrial applications—including steel mill rolling stands,cement kiln drives,and large blowers—also rely on the 3500/61 to protect against imbalance,misalignment,or rub-induced damage.Beyond direct machine protection,the module often feeds status signals to central control rooms for operator awareness or to historians for root-cause analysis.Across all these scenarios,the 3500/61 delivers the deterministic,auditable,and maintainable output layer that modern asset protection strategies demand.

Related Products

3500/62:Redundant Relay Module Interface that pairs with two 3500/61 modules for 1oo2 redundancy

3500/65:TMR Voting Relay Module for triple-redundant(2oo3)output voting,used with three 3500/61 cards

3500/42:4-channel vibration input module whose alarm outputs commonly drive the 3500/61

3500/45:Position monitor module for thrust,eccentricity,or valve position—frequently linked to 3500/61 trip relays

3500/15:Basic rack interface module required for non-redundant 3500/61 installations

3500/22:Enhanced rack interface with Modbus TCP,enabling remote monitoring of 3500/61 status

3500/25:TMR-compliant main frame for use with 3500/65 and multiple 3500/61 modules in SIL3 environments

Installation and Maintenance

Pre-installation preparation:Before installing the 3500/61,verify that the 3500 rack is powered down and that the correct terminal block(typically 3500/TB61)is mounted to the module’s rear connector.Confirm that all field devices connected to the relay contacts(e.g.,solenoid valves,DCS dry contacts)fall within the 2 A 30 V DC rating to avoid contact welding or premature wear.Ensure the 3500 Configuration Software has been used to assign each relay to its intended alarm source and set the desired fail-safe state(energize-to-trip or de-energize-to-trip).

Maintenance recommendations:The 3500/61 requires no routine calibration but should be inspected annually for signs of relay contact pitting,especially in high-cycle applications.Use the front-panel LEDs to verify relay activation during functional tests—do not rely solely on software status.If a relay fails,replace the entire 3500/61 module;individual relays are not field-serviceable.Always perform a full system download after replacement to restore configuration.Store spare 3500/61 units in static-safe packaging at ambient temperature to preserve relay spring tension and contact integrity.

Product Guarantee

Every 3500/61 we supply is either brand-new original from Bently Nevada(Baker Hughes)or a fully refurbished unit that has undergone comprehensive functional testing—including relay contact resistance measurement,coil activation verification,and communication integrity checks with a live 3500 rack.We guarantee compatibility with all standard 3500 chassis and configuration tools.Each 3500/61 comes with a 12-month warranty covering defects in materials and workmanship,backed by technical engineers experienced in machinery protection system integration.Our commitment ensures your 3500/61 delivers decades of reliable service—the hallmark of Bently Nevada’s legacy in industrial asset protection.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!