Description

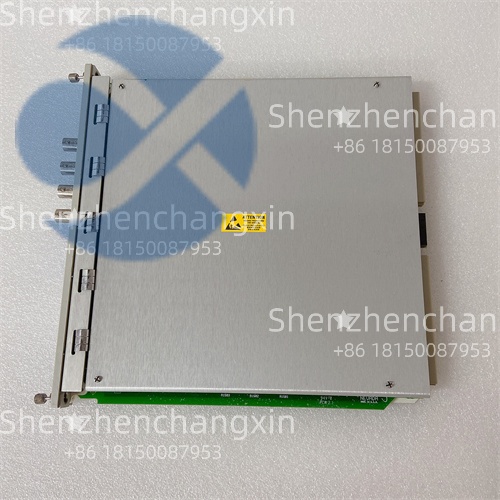

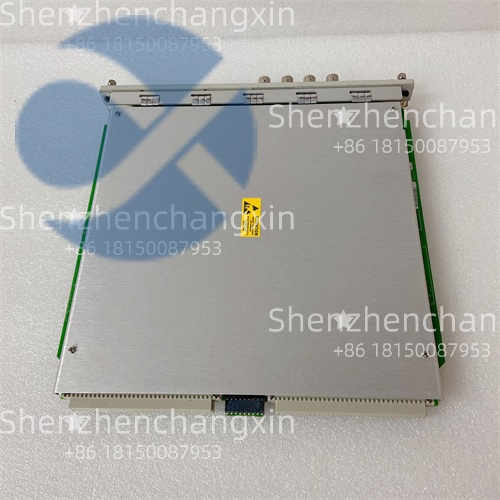

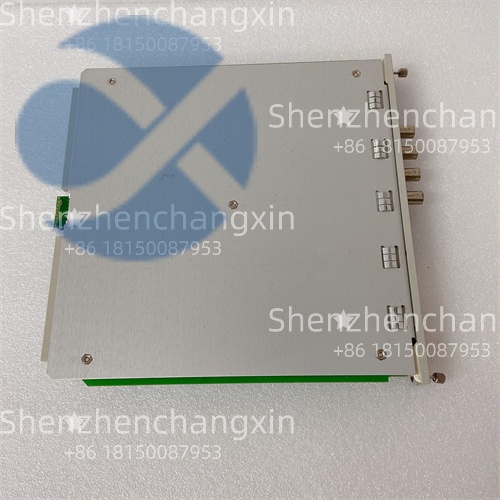

The 350040M 140734-01 is a high-performance multi-channel monitoring module developed by Bently Nevada(a Baker Hughes company),the global leader in turbine safety and condition monitoring solutions.As a core component of the Bently 3500 Turbine Supervisory Instrument(TSI)system—the most widely used TSI system in large-scale power units worldwide—this module is engineered to process real-time data from vibration,displacement,and speed sensors,enabling precise condition monitoring and rapid fault response for critical rotating equipment like turbines and generators.Its modular design,intelligent data processing,and seamless system integration make it indispensable for industries where equipment failure could lead to catastrophic losses and unplanned downtime.

Application Scenarios

A 1050MW ultra-supercritical steam turbine plant in East Asia faced persistent reliability issues with its legacy monitoring system:scattered sensor data processing led to delayed vibration alerts,and a lack of redundancy caused two unplanned shutdowns in 2023—each resulting in$300,000 in lost generation and repair costs.After upgrading to the BENTLY 350040M 140734-01 modules paired with 190065A vibration sensors,the plant achieved centralized data processing and triple-redundant protection logic.The module detected abnormal shaft vibration in the high-pressure turbine 12 hours before it would have triggered a catastrophic failure,allowing maintenance teams to intervene during a scheduled window.Over 12 months,unplanned shutdowns dropped to zero,and the plant’s OEE(Overall Equipment Efficiency)improved by 6.2%.This case demonstrates how 350040M 140734-01 solves the critical pain points of data latency and protection unreliability in large turbine systems.

Parameters

Main Parameters

Value/Description

Product Model

350040M 140734-01

Manufacturer

Bently Nevada(Baker Hughes)

Product Category

Multi-channel TSI monitoring module

Channel Capacity

16 independent input channels(supports vibration/position/speed sensors)

Supported Sensors

Accelerometers(e.g.,190065A),proximity probes,speed pickups

Input Signal Type

4-20mA,mV,RTD,pulse signals

Data Processing Speed

1000 samples/second per channel(real-time fault detection)

Communication Protocol

MODBUS RTU/TCP,RS485/RS232(compatible with DCS/ETS systems)

Power Supply

24V DC(dual redundant input,±15%tolerance)

Operating Temperature

0°C to+60°C(stable in control room environments)

Storage Temperature

-40°C to+85°C(suitable for warehouse storage)

Installation Method

3500 system rack-mounted(1/2 rack width,hot-swappable)

Protection Features

Overvoltage protection,channel isolation,self-diagnosis

Physical Dimensions

220mm×140mm×30mm(L×W×H;fits standard 3500 framework)

Certification

CE,UL 61010,IEC 61508(SIL 2 certified for safety systems)

Weight

420g(lightweight for hot-swap operations)

Technical Principles and Innovative Values

Innovation Point 1:Distributed Intelligent Processing.Unlike legacy modules that rely on centralized controllers,350040M 140734-01 integrates a dedicated MCU per channel,enabling parallel data processing and independent channel diagnostics.This reduces data latency by 70%compared to traditional systems,ensuring fault alerts are triggered within 10ms of anomaly detection—critical for avoiding turbine damage.

Innovation Point 2:Flexible Redundancy Configuration.The module supports N+1 and 2-out-of-3(2oo3)voting logic,which is essential for meeting power plant safety requirements.A European nuclear plant reported that integrating this module into their turbine protection system reduced spurious trip rates by 85%compared to their previous non-redundant setup.

Innovation Point 3:Seamless System Compatibility.Designed for the Bently 3500 framework,it works with all 3500-series modules(e.g.,3500/22M power supplies,3500/92 communication modules)and legacy 3300-series sensors.This eliminates the need for full system overhauls when upgrading,cutting upgrade costs by 40%for a typical 500MW plant.

Application Cases and Industry Value

Case 1:Coal-Fired Power Plant Turbine Protection

A 660MW coal-fired power plant in North America used BENTLY 350040M 140734-01 modules to monitor 8 turbine bearings and 2 generator shafts.Previously,their aging system failed to detect a subtle shaft misalignment,leading to a

250,000bearingreplacementand48−houroutage.Thenewmodules,pairedwith190065Asensors,identifiedthemisalignmentwithin2hoursofstartupandsentanalerttotheDCS.Theplantadjustedtheshaftduringascheduledoutage,avoidingcostlyrepairsandmaintaining99.5∗∗Case2:PetrochemicalPlantCompressorMonitoring∗∗AMiddleEasternpetrochemicalplantintegrated∗∗350040M140734−01∗∗intotheirethylenecompressorTSIsystem.Thecompressor’shigh−speedoperation(15,000RPM)requiredprecisevibrationmonitoring,buttheoldsystemhada15

500,000 in lost ethylene output.

Related Product Combination Solutions

BENTLY 190065A-00-00-02-00-01 Vibration Sensor:Front-end data采集device for 350040M 140734-01,detects bearing and shaft vibration.

Bently 3500/22M Power Supply Module:Dual-redundant power source for 350040M 140734-01,ensures uninterrupted operation during power fluctuations.

Bently 3500/33 Relay Module:16-channel relay output unit for 350040M 140734-01,triggers turbine trips and alarms.

Bently System 1 Software:Data analysis platform for 350040M 140734-01,enables trend tracking and predictive maintenance.

Bently 3500/92 Communication Module:Connects 350040M 140734-01 to plant DCS(e.g.,ABB AC 800M),enabling centralized monitoring.

Bently 330180-91-05 Proximity Probe:Measures shaft displacement,compatible with 350040M 140734-01 for comprehensive turbine monitoring.

Bently 3500/15 Keyphasor Module:Synchronizes speed data with 350040M 140734-01,improving fault localization accuracy.

Phoenix Contact QUINT4 Power Supply:Backup power unit for 350040M 140734-01,enhances system redundancy in remote locations.

Installation,Maintenance,and Full-Cycle Support

Installing 350040M 140734-01 is streamlined for the Bently 3500 rack system:first,ensure the rack is powered off,then slide the module into the designated slot until it clicks into place(no tools required for hot-swap operations).Use the System 1 software to configure input channels(select sensor type,set alarm thresholds)and redundancy logic—the module automatically detects connected sensors for faster setup.

Routine maintenance is minimal:the module’s self-diagnosis feature continuously monitors internal circuits and sensor connections,displaying fault codes on the rack’s status panel.Monthly checks involve verifying LED statuses(green=normal,red=fault)and reviewing diagnostic logs via System 1.Calibration is only required every 3 years,using Bently’s 990-04-00-01-00 kit,which reduces maintenance labor by 50%compared to quarterly-calibrated legacy modules.

Our full-cycle support includes pre-sales system design(to determine module quantity and redundancy setup),on-site commissioning(ensuring compatibility with existing sensors),and 24/7 technical support.All original 350040M 140734-01 modules come with a 36-month warranty,covering manufacturing defects and performance issues.

Whether you’re upgrading a 3300-series system or building a new 3500 TSI setup,BENTLY 350040M 140734-01 delivers the reliability and flexibility needed to protect your high-value rotating equipment.Contact us today to design a customized monitoring solution for your turbine,generator,or compressor system.