Description

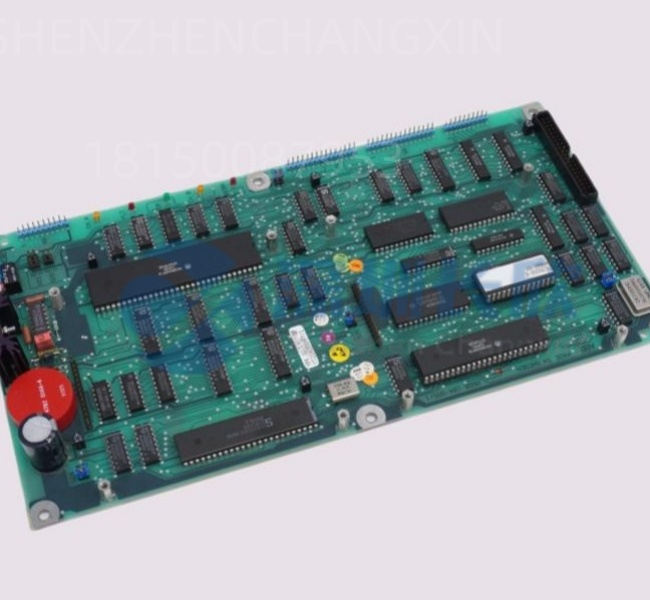

The YASKAWA SGMAS-02ACA41 is a compact, high-performance AC servo motor from Yaskawa’s renowned Sigma Series, designed for demanding industrial motion control applications. With a continuous output of 200 W (0.2 kW) and a rated speed of 3000 RPM, it delivers precise torque and position control through an integrated 2500-pulse-per-revolution incremental encoder.

Engineered for reliability in harsh environments, the SGMAS-02ACA41 features oil-resistant cabling, IP65-rated protection on the shaft side, and low-inertia rotor design—making it ideal for high-cycle automation tasks where responsiveness and durability are critical.

Application Scenarios

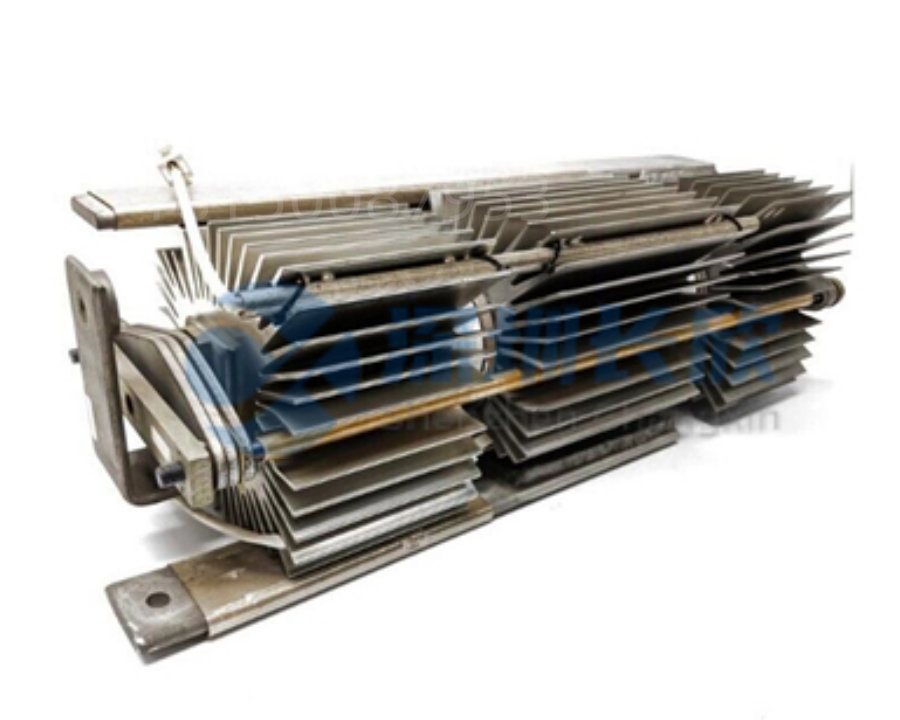

At a Japanese electronics assembly plant, a high-speed PCB insertion machine suffered from inconsistent component placement due to motor overheating and encoder signal drift in its legacy servo system. Engineers replaced the outdated units with YASKAWA SGMAS-02ACA41 motors paired with SGDH servo drives. The new setup delivered stable 3000 RPM operation with <±0.02° positioning error—even during 24/7 production runs. The oil-resistant cable jacket also prevented degradation from nearby lubricant sprays. “Cycle time dropped by 18%, and unplanned stops vanished,” reported the automation lead. This real-world success underscores how the SGMAS-02ACA41 transforms precision, uptime, and total cost of ownership in compact automation cells. Parameter 表格 Technical Principles and Innovative Values Innovation Point 1: Integrated 2500 PPR Encoder with Commutation Signals The SGMAS-02ACA41 embeds a high-resolution 2500-line incremental encoder that outputs not only A/B quadrature pulses but also UVW Hall-equivalent signals for brushless commutation—eliminating the need for external sensors and simplifying drive integration. Innovation Point 2: Oil-Resistant Cable Standardized Across Sigma Series Unlike generic servos, the SGMAS-02ACA41 ships with factory-installed oil-resistant cabling as standard, crucial for automotive, machining, and food packaging lines where exposure to cutting fluids or lubricants is common. Innovation Point 3: Low-Inertia Rotor for Ultra-Fast Response With a rotor inertia of just 0.11 × 10⁻⁴ kg·m², the SGMAS-02ACA41 achieves rapid acceleration/deceleration—ideal for pick-and-place, labeling, and indexing applications requiring sub-10 ms settling times. Innovation Point 4: Backward Compatibility with SGDH & SGDM Drives Despite being part of the modern Sigma platform, the SGMAS-02ACA41 maintains pin-compatible wiring with older Yaskawa drives like SGDH, enabling seamless upgrades without rewiring entire machines. Application Cases and Industry Value In a North American medical device manufacturer, syringe-filling robots used legacy servos that failed every 6 months due to cable jacket cracking from repeated flexing near oil mist. After switching to YASKAWA SGMAS-02ACA41. the motors operated continuously for over 24 months with zero cable-related failures. The combination of flexible, oil-resistant cabling and robust encoder sealing ensured compliance with ISO 13485 cleanroom standards. Similarly, in a European cookie-packaging line, the SGMAS-02ACA41 drove a horizontal form-fill-seal (HFFS) film feed mechanism. Its consistent torque delivery at low speeds (50–200 RPM) eliminated film slippage, reducing waste by 12% annually. Operators praised the motor’s quiet operation and minimal heat generation—even in enclosed cabinets. Related Product Combination Solutions YASKAWA SGDH-02AE: Compact servo amplifier—native support for SGMAS-02ACA41 with auto-tuning YASKAWA SGMAS-04ACA41: 400W version—direct power upgrade within same frame size YASKAWA JZSP-CKI01: Encoder feedback cable—replacement or extension for SGMAS-02ACA41 OMRON G5LE-1: Safety relay—used in E-stop circuits interfacing with SGMAS-02ACA41 drive enable ROCKWELL Kinetix 350: Alternative servo platform—but SGMAS-02ACA41 offers superior value in Yaskawa-centric plants BOSCH Rexroth IndraDrive: Competitor solution—lacks the plug-and-play simplicity of Sigma ecosystem YASKAWA MP2300: Motion controller—orchestrates multiple SGMAS-02ACA41 axes via Mechatrolink ABB ACS355: General-purpose VFD—not suitable for positioning; highlights why SGMAS-02ACA41 is essential for servo-grade tasks Installation, Maintenance, and Full-Cycle Support Installation of the YASKAWA SGMAS-02ACA41 is streamlined: mount using standard M4 bolts on the IEC 60034 flange, connect the combined power/encoder cable to a compatible Sigma drive (e.g., SGDH), and secure strain relief. No encoder alignment or calibration is needed—the motor is factory-zeroed. For optimal performance, ensure adequate airflow around the motor housing and avoid routing cables parallel to high-voltage lines. Maintenance is minimal due to sealed bearings and solid-state construction. However, periodic inspection of the shaft seal (for IP65 integrity) and cable jacket (for cuts or abrasion) is recommended in abrasive environments. The motor contains no brushes or consumables, ensuring >30.000 hours of maintenance-free operation under normal conditions.

Every SGMAS-02ACA41 we supply undergoes:

Insulation resistance testing (>100 MΩ @ 500 VDC)

Shaft runout verification (<0.02 mm TIR)

Encoder signal integrity check (A/B/Z/UVW waveforms)

Visual inspection for cosmetic and mechanical defects

Units are cleaned, tagged with original Yaskawa labels, and backed by a 12-month warranty. We also provide cross-reference support for obsolete models (e.g., SGMA-02A vs. SGMAS-02A) and assist with drive parameter templates.