Description

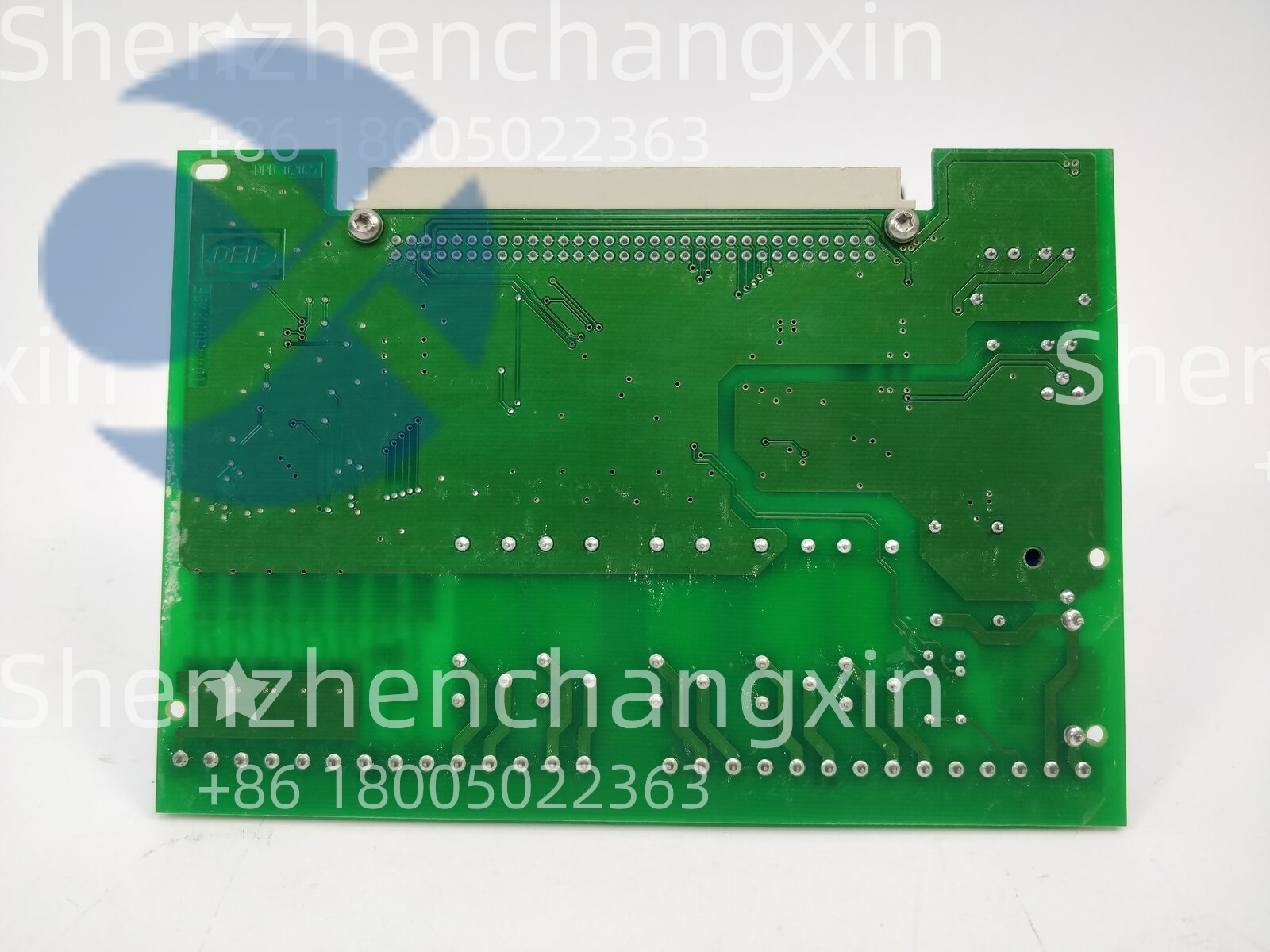

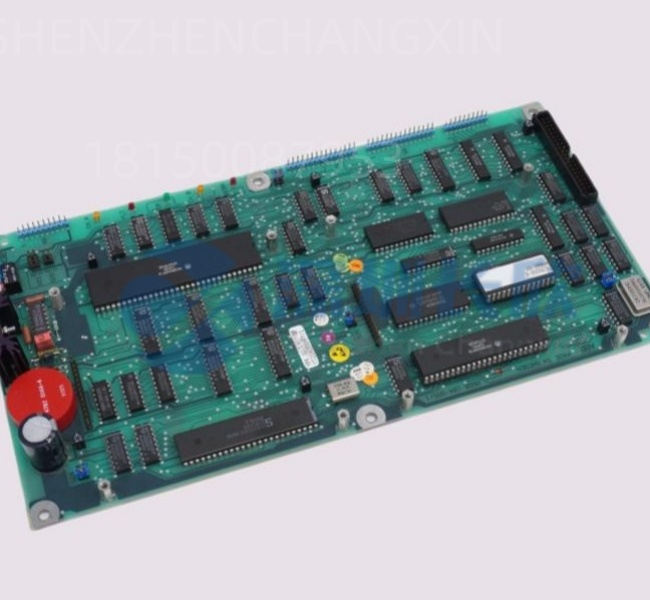

TheDEIF 1044500270Fis a specialized control interface module manufactured by DEIF,designed for seamless integration within power management systems.This robust component serves as a critical interface between sensors,controllers,and monitoring systems in industrial automation applications.

Application Scenarios

In a large data center’s backup power system,theDEIF 1044500270Fserves as the central communication hub between multiple generator controllers and the building management system.During a recent city-wide power outage,the module efficiently coordinated data from 12 generator sets,processing over 200 parameters simultaneously and ensuring uninterrupted power transition to critical server racks.The module’s robust communication protocols maintained data integrity even during voltage fluctuations,preventing potential data loss worth millions of dollars and ensuring 99.999%uptime for financial transaction processing systems.

Parameter

Main Parameters

Value/Description

Product Model

1044500270F

Manufacturer

DEIF

Product Category

Control Interface Module

Operating Voltage

24VDC±10%

Communication Protocols

CANbus,RS485,Modbus RTU

Data Processing Speed

100ms cycle time

Input Channels

16 digital/8 analog

Output Channels

8 relay/4 analog

Operating Temperature

-25°C to+70°C

Protection Rating

IP40

Memory Capacity

2MB flash storage

Firmware Update

USB and remote capable

Certification

CE,UL,DNV-GL

Technical Principles and Innovative Values

Innovation Point 1:TheDEIF 1044500270Ffeatures advanced signal conditioning technology that provides±0.1%measurement accuracy across all analog channels,significantly outperforming standard industrial modules that typically achieve only±0.5%accuracy.

Innovation Point 2:Utilizing dual-processor architecture,the module simultaneously handles real-time data processing and communication tasks without performance degradation,ensuring consistent 100ms cycle times even during peak load conditions.

Innovation Point 3:Built-in data buffering and automatic retry mechanisms maintain communication integrity during network disruptions,preventing data loss and ensuring continuous system monitoring without requiring manual intervention.

Application Cases and Industry Value

At a semiconductor manufacturing facility in Taiwan,theDEIF 1044500270Fwas deployed to monitor and control critical power distribution across cleanroom environments.The module successfully integrated with 15 different equipment brands through its multi-protocol support,reducing integration time by 40%compared to traditional solutions.During a voltage sag event,the module’s rapid response prevented production line shutdowns,saving an estimated$2.3 million in potential production losses and material spoilage.Facility managers reported 99.98%operational reliability over two years of continuous operation.

Related Product Combination Solutions

DEIF AGC-200-Generator controller for comprehensive power management

DEIF PPM-100-Power protection module for voltage stabilization

DEIF MSC-4-Multi-signal conditioner for sensor integration

DEIF RCI-1-Remote communication interface for SCADA systems

DEIF GCP-300-Generator control panel for complete solutions

DEIF PCS-3000-Power control system for large installations

DEIF WS-500-Weather station interface for environmental monitoring

DEIF MMC-800-Multi-master controller for complex automation systems

Installation,Maintenance,and Full-Cycle Support

Installation and Commissioning:TheDEIF 1044500270Ffeatures tool-less DIN rail mounting and intuitive plug-and-play connectivity that reduces installation time by 60%.Color-coded connectors and auto-addressing functionality eliminate configuration errors,while the integrated web interface allows commissioning without specialized software tools.

Maintenance and Support:With built-in self-monitoring and predictive maintenance alerts,the1044500270Fprovides early warning of potential issues before they impact system performance.Our global technical support team offers 24/7 remote diagnostics and firmware updates,ensuring maximum system availability.Comprehensive documentation and online training resources enable your technical staff to perform advanced troubleshooting and system optimization.