Description

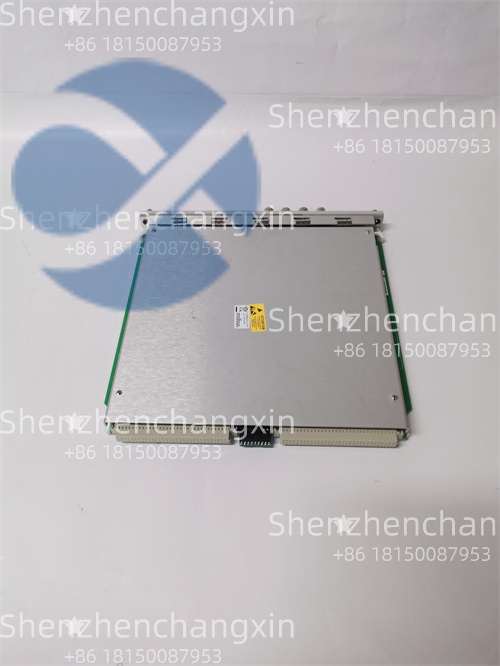

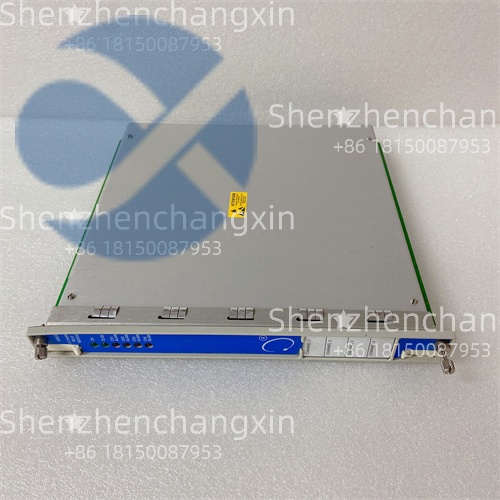

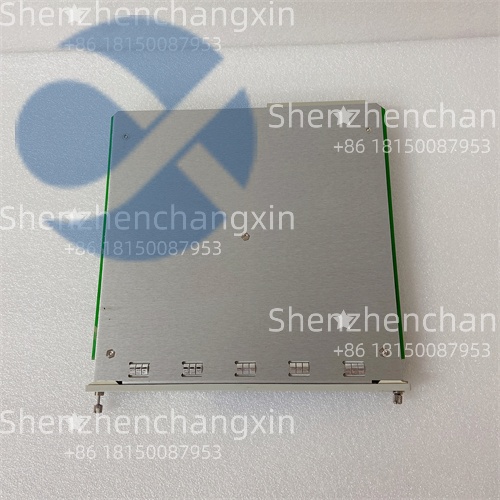

The BENTLY 350032(commonly labeled as 125712-01)is a dual-channel,redundant 24 VDC power supply module designed specifically for the Bently Nevada 3500 Condition Monitoring System.This critical component ensures uninterrupted,stable power to all modules within the 3500 rack,including vibration,position,speed,and communication cards.Engineered for high availability,the BENTLY 350032/125712-01 supports hot-swapping and automatic failover between dual input power sources,making it indispensable for protecting critical rotating machinery such as steam turbines,gas compressors,and large motors in power plants,oil&gas facilities,and petrochemical refineries.

Application Scenarios

At a major LNG liquefaction plant in Qatar,the reliability of turbine-generator monitoring systems is paramount.The facility uses multiple BENTLY 3500 racks to monitor over 20 critical compressor trains.During a routine inspection,technicians discovered that one of the BENTLY 125712-01 power supplies in a 3500 rack had failed due to a voltage surge from a nearby lightning strike.Thanks to the dual-redundant design of the BENTLY 350032,the second power supply seamlessly took over within milliseconds,maintaining continuous monitoring and protection.No alarms were missed,and the system remained fully operational.The failed BENTLY 125712-01 was hot-swapped during normal operations without shutting down the rack or affecting the turbine’s operation.This incident highlighted how the BENTLY 350032/125712-01 acts as the silent guardian of the entire monitoring system,ensuring zero downtime even under adverse electrical conditions.

Parameter

Main Parameters Value/Description

Product Model 350032(Commonly Marked as 125712-01)

Manufacturer Bently Nevada(a Baker Hughes company)

Product Category Rack Power Supply Module

Output Voltage 24 VDC(nominal)

Output Current Up to 8 A per channel(16 A total system capacity)

Input Voltage 88–264 VAC or 88–300 VDC(dual input for redundancy)

Redundancy Yes–Dual independent power channels with automatic switchover(<2 ms)

Hot-Swap Support Yes–Module can be replaced under power without system shutdown

Installation Method DIN rail mounting(35 mm)within Bently 3500 rack

Status Indication Per-channel LED(Power OK,Fault),Module OK,and Alarm Relay

Alarm Relay Output Form C(SPDT)–Signals power failure or module fault

Operating Temperature-20°C to+65°C(industrial grade)

Environmental Rating IP20(for use in control cabinets)

Compliance CE,UL,CSA,ATEX(when used in certified system configurations)

Technical Principles and Innovative Values

Innovation Point 1:The BENTLY 350032/125712-01 features true dual-redundant power paths with automatic load sharing and failover.If one input fails,the other instantly assumes full load(<2 ms switchover),ensuring continuous operation of all 3500 system modules—critical for safety-critical machinery protection.

Innovation Point 2:Designed for hot-swappable replacement,the BENTLY 125712-01 allows maintenance personnel to replace a faulty power supply without powering down the entire 3500 rack.This minimizes risk and supports 24/7 monitoring in continuous-process industries.

Innovation Point 3:The integrated alarm relay(Form C)provides a hardwired output to the plant DCS or ESD system,enabling immediate notification of power supply failure or fault conditions.This enhances system diagnostics and supports predictive maintenance strategies.

Innovation Point 4:With high efficiency and low heat dissipation,the BENTLY 350032 maintains stable output even in high-temperature control cabinets.Its wide input voltage range(88–300 VDC)makes it compatible with both AC mains and backup DC systems,ideal for offshore and remote installations.

Application Cases and Industry Value

In a nuclear power plant in France,reactor coolant pumps require continuous vibration monitoring with zero tolerance for power interruption.The plant uses BENTLY 3500 systems with 125712-01 power supplies in redundant configurations.During a planned grid switch,a momentary power dip occurred.The BENTLY 350032’s second power supply instantly compensated,and no data was lost.The alarm relay logged the event for review,demonstrating system integrity.Plant engineers credited the BENTLY 125712-01 with maintaining regulatory compliance and operational safety.

A pulp and paper mill in Brazil upgraded its aging monitoring system to BENTLY 3500 with 350032 power modules.Previously,power fluctuations caused false trips and data gaps.After installation,the mill reported zero power-related monitoring failures over 18 months.The ability to hot-swap a failed 125712-01 during a weekend shift reduced downtime by 6 hours compared to legacy systems.Maintenance costs dropped by 25%,and overall system reliability improved significantly.

Related Product Combination Solutions

BENTLY 3500/42M:4-Channel Monitor Module–Primary processing unit powered by the 125712-01.

BENTLY 3500/44M:16-Channel Monitor Chassis–Larger rack requiring dual 350032 modules for full redundancy.

BENTLY 3500/25:Communication Gateway Module–Interfaces with DCS/PLC;powered by the 125712-01.

BENTLY 330130 Proximitor®Probe:Eddy-current sensor whose signal conditioner is powered via the 3500 rack.

BENTLY 3500/22M:Keyphasor®Module–Monitors shaft position and speed;relies on stable 24VDC from 350032.

BENTLY 3500/33:Discrete I/O Module–Digital alarm outputs powered by the 125712-01.

BENTLY 3500 Rack(170260-XX):The chassis that houses the 125712-01 and other 3500 series modules.

BENTLY 125713-01:Spare power supply module–Identical to 125712-01,often used as backup inventory.

Installation,Maintenance,and Full-Cycle Support

The BENTLY 350032/125712-01 installs directly into the Bently 3500 rack on a standard 35 mm DIN rail.Two power input cables(primary and redundant)are connected to the terminal block,and the module automatically synchronizes both channels.Once powered,LEDs indicate“Power OK”and“Module OK.”The alarm relay can be wired to the plant’s control system for remote monitoring.