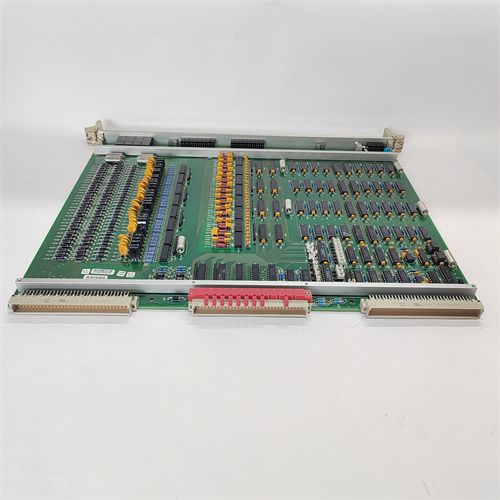

Description

The Yaskawa JEPMC-PC040 is a powerful embedded PC-based motion controller designed for Yaskawa’s MP2300 and MP3300 machine automation platforms. Combining a real-time operating system (Windows CE), high-speed CPU, and integrated motion control engine, it enables complex, multi-axis coordination—supporting up to 64 axes via MECHATROLINK-III or EtherCAT. The JEPMC-PC040 serves as both a motion CPU and application host, capable of running custom HMI, vision integration, data logging, and communication protocols—all within a single compact module.

Application Scenarios

At a high-speed flexible packaging line in Germany, a legacy PLC struggled to synchronize 24 servo axes during product changeovers, causing jams and downtime. Engineers replaced the controller with a Yaskawa MP3300 system featuring the JEPMC-PC040. Leveraging its built-in motion engine and Windows CE environment, they deployed a custom HMI with recipe management and real-time cam profiling. Cycle times dropped by 18%, and changeover time was reduced from 45 minutes to under 8 minutes. The JEPMC-PC040’s ability to run motion logic and operator interface on one platform eliminated external PCs—simplifying architecture and improving reliability.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Unified Motion + Application Platform

The JEPMC-PC040 eliminates the need for separate HMI or IPC units by hosting both real-time motion control and user applications (e.g., recipe managers, OPC servers) on one module—reducing footprint and cost.

Innovation Point 2: Deterministic Motion on Windows CE

Despite using a commercial OS, Yaskawa’s real-time kernel extension ensures microsecond-level motion determinism—critical for flying shear, electronic gearing, and CNC interpolation.

Innovation Point 3: Native MECHATROLINK-III Integration

Direct support for Yaskawa’s high-speed servo network enables jitter-free synchronization of dozens of Σ-7 servos with minimal configuration.

Innovation Point 4: Open Development Environment

Developers can create custom .NET Compact Framework apps in C# or VB.NET that interact directly with motion variables—enabling advanced analytics, cloud connectivity, or vision-guided robotics.

Application Cases and Industry Value

In a Japanese semiconductor wafer handling system, precision alignment required sub-micron coordination between 8 linear motors and 4 rotary stages. The JEPMC-PC040 executed complex path planning while simultaneously processing camera feedback via a custom C# application. Over 18 months, the system achieved 99.98% uptime, with zero motion-related faults. The integrator noted that the JEPMC-PC040’s “single-box intelligence” cut development time by 40% compared to traditional PLC + IPC architectures.

Related Product Combination Solutions

Yaskawa MP3300: Main controller base—hosts the JEPMC-PC040 and I/O modules

Yaskawa Σ-7 Servo Drives: High-response servos—natively synchronized via MECHATROLINK-III from JEPMC-PC040

MotionWorks IEC Pro: Engineering software—used to program PLC, motion, and HMI logic for JEPMC-PC040

JEPMC-MXN01: MECHATROLINK-III master module—optional for expanded axis count or redundancy

JEANC-EP01: EtherCAT master module—enables third-party drive integration alongside Yaskawa servos

CF Cards (Yaskawa-approved): For application storage, data logging, and firmware backup

SGDV / SGD7S Servo Amplifiers: Paired with JEPMC-PC040 for high-bandwidth motion control

Yaskawa HMI (GP4000): Optional external display—though often unnecessary due to built-in HMI capability

Installation, Maintenance, and Full-Cycle Support

The JEPMC-PC040 installs directly into the MP2300/MP3300 rack and draws power from the backplane. Configuration is performed via MotionWorks IEC over Ethernet. Applications can be deployed via CF card or network download. The module supports remote desktop (VNC) for diagnostics and includes watchdog timers for automatic recovery.

For long-term reliability, avoid excessive vibration and ensure adequate ventilation. The internal flash memory is rated for >100.000 write cycles—suitable for continuous data logging.

We supply genuine, factory-tested JEPMC-PC040 units with full compatibility verification for your MP series firmware version. Each module undergoes boot-up validation, motion loop test, and communication stress testing. Backed by a 12-month warranty and access to Yaskawa-certified engineers, our JEPMC-PC040 solutions ensure your high-performance machines stay intelligent, synchronized, and productive.

Contact us for a customized solution—including application migration support, performance tuning, or global logistics for OEM production lines. When your machine demands more than just motion—demand intelligence in a single module.