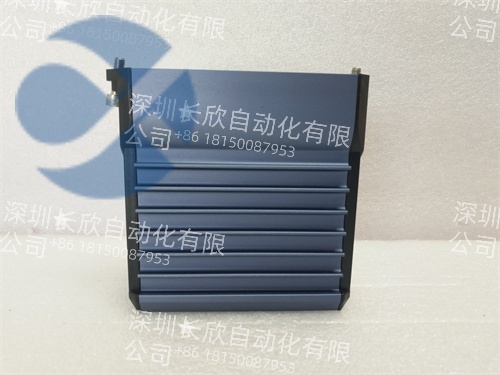

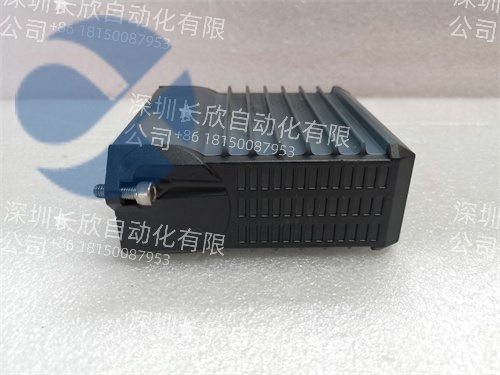

Product Overview

The FOXBORO FBM230 P0926GU is a highly versatile field device system integrator(FDSI)module manufactured by FOXBORO,designed specifically for industrial automation and process control applications.This advanced communication module serves as a critical interface between field devices and the EcoStruxure Foxboro DCS system,providing seamless integration of various serial communication devices into modern distributed control systems.TheFOXBORO FBM230 P0926GUoffers exceptional flexibility with its four independently configurable serial ports,each capable of supporting RS-232,RS-422,or RS-485 communication standards,making it ideal for connecting diverse field instruments and devices in complex industrial environments

.

Engineered for reliability in demanding industrial settings,theFOXBORO FBM230 P0926GUfeatures robust construction that meets G3 grade environmental requirements,ensuring stable operation in harsh conditions.The module supports up to 2000 DCI block connections and can communicate with up to 64 RS-485 devices or 4 directly connected RS-232/RS-422 devices,providing extensive connectivity options for process automation systems.TheFOXBORO FBM230 P0926GU’s universal hardware design allows for dynamic loading of different software drivers,enabling protocol customization and adaptation to specific field device requirements without hardware modifications

.

Technical Specifications

Parameter Name

Parameter Value

Product Model

FOXBORO FBM230 P0926GU

Manufacturer

FOXBORO

Product Type

Field Device System Integrator Module

Communication Ports

4 independent serial ports

Supported Protocols

RS-232,RS-422,RS-485

Maximum Device Connections

64 RS-485 or 4 direct RS-232/RS-422

DCI Block Connections

Up to 2000 connections

Power Supply

24V DC±5%,-10%

Power Consumption

7W maximum

Heat Dissipation

7W maximum

Operating Temperature

Industrial grade range

Environmental Rating

G3 grade(severe industrial environment)

Installation Type

Field installation

Communication Speed

300-115200 baud

Character Format

8-bit,parity optional,1-2 stop bits

Data Types Supported

Analog I/O,digital I/O,packed digital I/O

Maximum Digital I/O

Up to 64,000 digital points

ECB Block Cycle

500ms minimum

Channel Isolation

600V AC for 1 minute

Main Features and Advantages

Flexible Communication Configuration:TheFOXBORO FBM230 P0926GUstands out with its four independently configurable serial ports,each capable of supporting RS-232,RS-422,or RS-485 communication standards.This flexibility allows a singleFOXBORO FBM230 P0926GUmodule to connect multiple similar but not identical devices,eliminating the need for multiple specialized modules and reducing system complexity.The module’s physical wiring complies with EIA standards,ensuring compatibility with industry-standard cabling and connectors

.

Universal Hardware Platform:TheFOXBORO FBM230 P0926GUserves as a universal hardware platform that can be configured through software drivers downloaded from available protocol libraries.This approach enables the module to adapt to various field device protocols without requiring hardware changes.Standard software drivers are available as products,while custom drivers can be developed to meet specific application requirements.The dynamic download capability of these drivers ensures that theFOXBORO FBM230 P0926GUcan be easily updated and reconfigured to support new devices and protocols as they become available

.

Robust Industrial Design:Designed for deployment in challenging industrial environments,theFOXBORO FBM230 P0926GUfeatures channel isolation that can withstand 600V AC potential between any channel and ground for one minute without damage.The module’s G3 grade environmental rating ensures reliable operation in severe industrial conditions,including exposure to electrical noise,vibration,and temperature extremes.This robust design makes theFOXBORO FBM230 P0926GUsuitable for critical process control applications where reliability is paramount

.

High-Performance Data Processing:TheFOXBORO FBM230 P0926GUsupports multiple data types including analog input/output values,single digital input/output values,and packed digital input/output values(up to 32 digital points per connection).The module can handle up to 2000 analog I/O values or 64,000 digital I/O values,with control station access frequency as fast as 500 milliseconds.This high-performance capability ensures that theFOXBORO FBM230 P0926GUcan meet the demanding requirements of modern industrial automation systems

.

Application Field

TheFOXBORO FBM230 P0926GUfinds extensive application in process control systems across various industries,including chemical processing,oil and gas production,and power generation.In chemical plants,the module connects various process instruments such as pressure transmitters,temperature sensors,and flow meters to the DCS system,enabling real-time monitoring and control of critical process parameters.TheFOXBORO FBM230 P0926GU’s ability to support multiple communication protocols makes it particularly valuable in facilities with diverse instrumentation from different manufacturers,ensuring seamless integration and data exchange between legacy and modern field devices

.

In the oil and gas industry,theFOXBORO FBM230 P0926GUplays a crucial role in upstream and midstream operations,connecting remote field devices in drilling platforms,pipeline monitoring systems,and refinery process units.The module’s robust design and environmental tolerance make it suitable for deployment in harsh offshore environments and remote locations where maintenance access is limited.TheFOXBORO FBM230 P0926GU’s support for long-distance communication via RS-485 enables reliable data transmission over extended distances,making it ideal for distributed control applications in large-scale industrial facilities

.

Manufacturing automation represents another significant application area for theFOXBORO FBM230 P0926GU,where it integrates various production equipment such as PLCs,robots,and specialized machinery into centralized control systems.The module’s flexible configuration capabilities allow it to adapt to different manufacturing processes and equipment types,providing a unified interface for monitoring and controlling production lines.In pharmaceutical and food processing industries,theFOXBORO FBM230 P0926GUensures compliance with strict quality control requirements by enabling precise monitoring of process parameters and equipment status

.

Related Products

FOXBORO FBM231:Redundant version with dual-port device support for enhanced reliability

FOXBORO FBM233 P0926GX:Similar communication module with enhanced features

FOXBORO FBM242 RH916TA:Digital I/O module for discrete signal processing

FOXBORO FCP280:Field control processor for DCS systems

FOXBORO FBM214:Analog input module for signal acquisition

FOXBORO FBM216:Digital input module with multiple channels

FOXBORO FBM218:Digital output module for control applications

FOXBORO FBM232:Ethernet I/O module for network connectivity

FOXBORO FBM242:Digital output module with multiple channels

FOXBORO FBM214B:Digital input module with HART communication support

Installation and Maintenance

Pre-installation preparation:Before installing theFOXBORO FBM230 P0926GU,ensure that the installation environment meets the specified G3 grade requirements for industrial environments.Verify that the power supply provides 24V DC within the specified tolerance range and that proper grounding connections are established.The module should be installed in a location that provides adequate ventilation for heat dissipation and protection from direct exposure to moisture,dust,and corrosive substances.All field wiring should be properly shielded and routed to minimize electrical interference,with terminal connections tightened to specified torque values to ensure reliable signal transmission

.

Maintenance recommendations:Regular maintenance of theFOXBORO FBM230 P0926GUshould include periodic inspection of status indicators,verification of communication link integrity,and monitoring of operating temperature conditions.The module’s diagnostic capabilities should be utilized to identify potential issues before they affect system operation.Firmware and software driver updates should be applied following manufacturer recommendations,with proper backup procedures followed to preserve system configuration.Environmental conditions should be monitored to ensure they remain within specified operating ranges,with particular attention to temperature,humidity,and vibration levels that could affect long-term reliability.Periodic cleaning of ventilation openings and inspection of cable connections will help maintain optimal performance and extend the service life of theFOXBORO FBM230 P0926GUmodule

.

Product Guarantee

We guarantee that everyFOXBORO FBM230 P0926GUmodule meets original manufacturer specifications and undergoes comprehensive testing before shipment.Each unit is backed by our technical support team with extensive experience in FOXBORO automation systems and industrial communication applications.Our commitment to customer satisfaction includes prompt technical support,complete documentation packages,and replacement guarantees for defective components.With extensive experience in process control systems,we provide expert guidance from selection through installation and maintenance,ensuring your investment delivers long-term value and operational reliability.Our quality assurance processes ensure that you receive a fully functional module capable of reliable performance in the most demanding industrial environments,with comprehensive support services to address any technical challenges that may arise during implementation and operation

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!