Description

Description

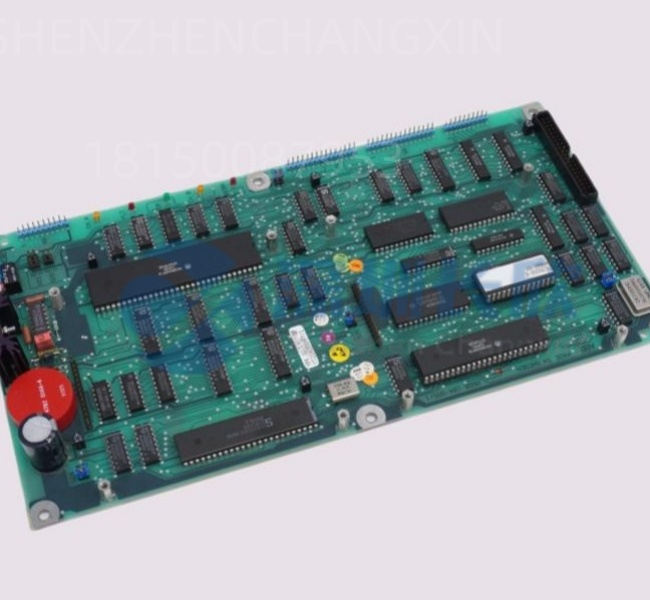

The General Electric DS200PTBAG1BAA is a specialized terminal board (terminal base) designed for use in GE Speedtronic™ Mark V turbine control systems. It serves as the field-wiring interface for pulse and timing-related I/O modules, such as the DS200PTCAG (Pulse/Timer Counter) or DS200PCCAG (Protection Core Controller), which are used to monitor and process high-speed signals from turbine speed probes, flow meters, encoders, and generator synchronization equipment.

Unlike general-purpose terminal boards, the DS200PTBAG1BAA is engineered with optimized trace routing, shielding, and terminal spacing to preserve signal integrity for fast-rising, low-amplitude pulses—ensuring accurate speed measurement, overspeed protection, and load-sharing control in critical power generation applications.

Application Scenarios

At a natural gas-fired peaker plant in Arizona, operators noticed inconsistent turbine speed readings during startup, occasionally causing false acceleration alarms. Diagnostics traced the issue to crosstalk and signal degradation on an older, non-dedicated terminal base handling magnetic pickup signals. After replacing it with a genuine GE DS200PTBAG1BAA, pulse waveforms from the speed probes remained clean even at 15.000 RPM. The dedicated layout and shielded paths of the DS200PTBAG1BAA eliminated noise coupling from adjacent relay circuits. Over the next year, zero speed-related trips occurred—demonstrating how this seemingly simple terminal board plays a vital role in functional safety and operational reliability.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Signal-Fidelity-Optimized Layout for Critical Timing Circuits

The DS200PTBAG1BAA uses controlled impedance traces, ground shielding, and physical separation between analog pulse inputs and digital outputs—minimizing EMI-induced jitter that could compromise overspeed detection or generator sync accuracy.

Innovation Point 2: Dedicated Architecture for High-Reliability Protection Functions

Unlike generic terminal bases, this unit is part of GE’s protection-class I/O pathway, ensuring that signals feeding into turbine trip logic maintain integrity from sensor to controller—supporting compliance with IEEE C37.90 and IEC 60255 standards.

Innovation Point 3: Seamless Hot-Swap Compatibility in Redundant Systems

When used in dual-redundant Mark V racks, the DS200PTBAG1BAA allows replacement of the plugged-in I/O module without disturbing field wiring—critical for online maintenance in baseload plants.

Innovation Point 4: Long-Term Availability for Life-Extended Turbine Fleets

With many Mark V systems operating beyond 25+ years, the continued supply of authentic DS200PTBAG1BAA units prevents forced obsolescence and supports regulatory compliance during safety system audits.

Application Cases and Industry Value

In a European combined-cycle plant, the DS200PTBAG1BAA interfaces with three redundant magnetic speed probes on a Frame 9E gas turbine. During a grid instability event, all three channels accurately captured a transient overspeed condition (112% NG), triggering a safe shutdown within 40 ms. Post-event analysis confirmed no signal distortion—validating the terminal board’s role in maintaining SIL-equivalent performance in mechanical protection systems.

In another case, a U.S. municipal utility uses the DS200PTBAG1BAA to acquire pulses from revenue-grade flow meters for steam allocation. The clean signal path enabled <0.5% totalization error over a 12-month billing cycle—critical for inter-departmental cost accounting.

Related Product Combination Solutions

GE DS200PTCAG1A: Pulse/Timer Counter I/O module—plugs directly into DS200PTBAG1BAA

GE DS200PCCAG1A: Protection Core Controller—uses pulse inputs for trip logic

GE DS200TBCAG1AAB: General-purpose terminal board—not suitable for high-speed pulse signals

GE Mark V I/O Chassis (e.g., DS200VSCA): Houses DS200PTBAG1BAA in protection or control racks

Bently Nevada 3300 Proximity Probes: Often wired through DS200PTBAG1BAA for vibration/speed

Honeywell MC-PDIS12: Functional alternative in Experion—but not compatible with Mark V

GE DS200TBXAG1A: High-density terminal base—lacks pulse-specific signal conditioning

Phoenix Contact PT 2.5/..-ST: Generic terminal block—not recommended due to noise susceptibility

Installation, Maintenance, and Full-Cycle Support

Installation requires aligning the DS200PTBAG1BAA with guide rails in the Mark V I/O chassis and pressing firmly until it seats into the backplane connector. For pulse signals, shielded twisted-pair cable must be used, with shields grounded at the controller end only to avoid ground loops.

Maintenance includes:

Verifying terminal torque (~0.4 N·m for 20 AWG)

Inspecting for corrosion on terminals or PCB

Checking for bent pins on the backplane connector

Ensuring no mixed use with non-pulse I/O modules

Every DS200PTBAG1BAA we supply undergoes:

Visual and mechanical inspection

Continuity and isolation testing (500 VDC)

Conformal coating integrity check

Compatibility verification with target I/O modules