Description

Description

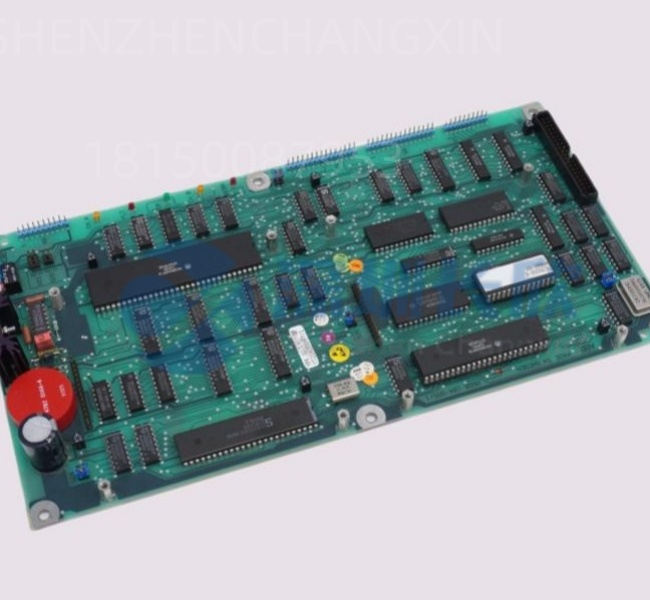

The General Electric DS3826-SSHRBCA is a legacy servo drive control board designed for the Mark IV Speedtronic gas/steam turbine control system. This specialized printed circuit board functions as a critical interface and signal processor within a servo control assembly, managing the command and feedback signals essential for the precise positioning of fuel valves, inlet guide vanes (IGVs), or other critical hydraulic/electro-hydraulic actuators.

Application Scenarios

In a power generation facility utilizing a GE Frame 5 or 6 gas turbine with a Mark IV control system, the reliable management of fuel flow is the determinant of power output, efficiency, and safety. The DS3826-SSHRBCA board resides within a dedicated servo drive cabinet. Its role is to act as the intelligent intermediary: it receives a positioning command from the main Mark IV controller, conditions this signal, and interfaces with the final power amplifier stage that drives the servo valve. Simultaneously, it processes the actuator’s position feedback signal (often from an LVDT). The board solves the critical pain point of maintaining signal integrity and control loop stability in an analog control system. Its precise operation ensures the fuel valve responds accurately to the controller’s demand. A fault in the DS3826-SSHRBCA can manifest as sluggish valve response, positioning errors, or a complete loss of control, potentially leading to inefficient combustion, turbine trips, or unsafe operating conditions, highlighting its role in both performance and protection.

Parameter

Technical Principles and Innovative Values

Innovation Point 1: Integrated Analog Control Loop Processing. The DS3826-SSHRBCA embodies the transition to more integrated digital control within the largely analog Mark IV architecture. It consolidates functions—such as command signal scaling, feedback demodulation, and PID (Proportional-Integral-Derivative) error calculation—onto a single, serviceable board. This integration improved reliability over earlier discrete component designs by reducing interconnection points and provided a more maintainable unit. Its design focused on delivering the precise, stable analog signal processing required for smooth actuator motion.

Innovation Point 2: Dedicated Safety and Monitoring Circuitry. Beyond basic control, this board incorporated critical monitoring logic for turbine protection. It continuously verifies the health of the servo loop, checking for discrepancies between the command signal and the actuator’s actual position (via LVDT feedback). It can also monitor for fault conditions like feedback loss or excessive error. In a fault scenario, the board can trigger an alarm or contribute to a safety trip, preventing the turbine from operating with a faulty control element. This built-in diagnostics was a significant step forward in system reliability.

Innovation Point 3: Customized Configuration for Specific Actuator Types. The “SSHRBCA” suffix likely denotes a specific configuration for a particular type of servo valve or actuator (e.g., specific current/voltage ranges, feedback type compatibility, or enable logic). This customization allowed GE to optimize the board’s performance for a given application—whether it was controlling a large fuel gas valve, a liquid fuel servo, or a steam turbine governor valve. This application-specific design ensured optimal dynamic response and stability for each control loop.

Application Cases and Industry Value

A chemical plant with a GE Frame 3 gas turbine driving a compressor train began experiencing intermittent “servo drive fault” alarms during seasonal load changes, causing unscheduled shutdowns. Diagnostics pointed to instability in the fuel control servo loop. The plant’s engineering team isolated the problem to a specific analog signal processing circuit on the DS3826-SSHRBCA board that had drifted with age and temperature sensitivity. Replacing the aging DS3826-SSHRBCA board with a tested, reconditioned unit restored the loop’s stability. The maintenance manager reported: “The new DS3826-SSHRBCA board eliminated the erratic faults immediately. The turbine now handles load transitions smoothly. For a legacy unit that is critical to our process, having access to a reliable, compatible spare like this is what keeps us running without the multi-million dollar cost of a full control system upgrade.”

Related Product Combination Solutions

Mark IV Control Module (e.g., DS200/DS300 series): The primary turbine controller (like a DS200TBCAG1) that generates the initial positioning command sent to the servo drive assembly containing the DS3826-SSHRBCA.

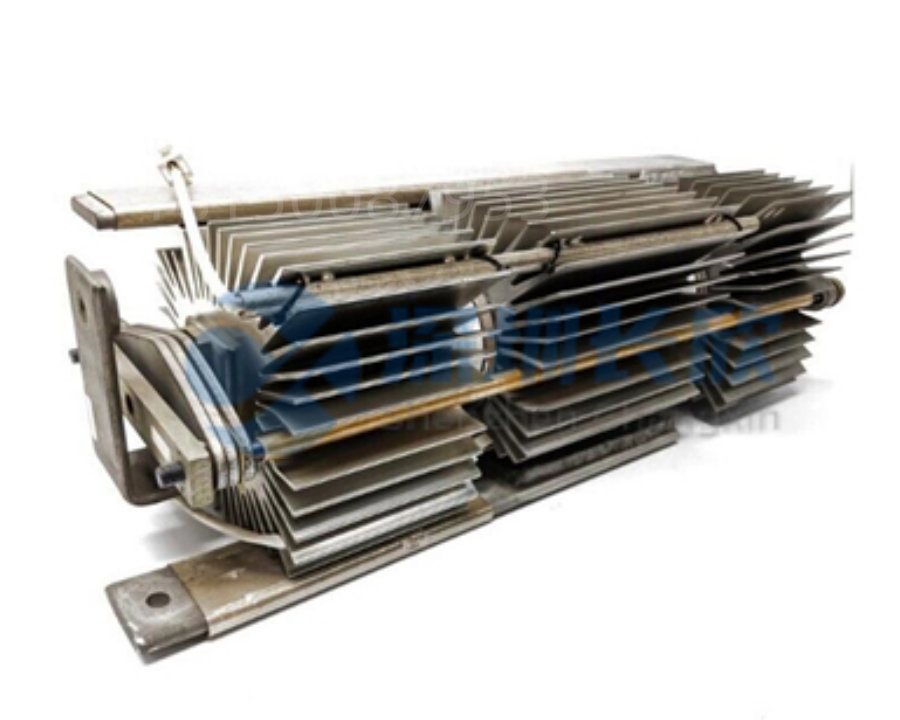

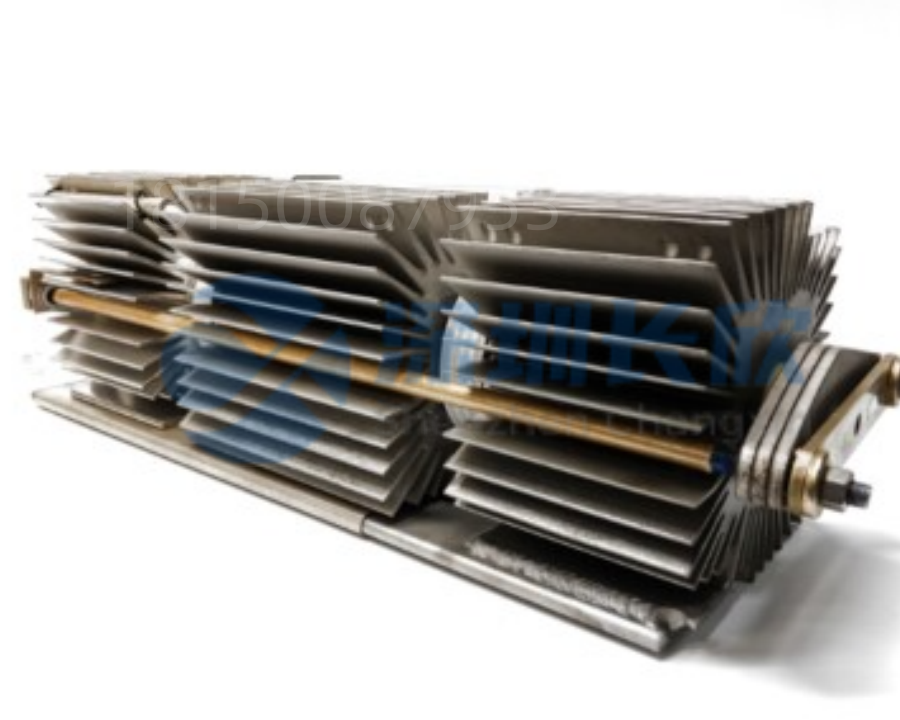

Servo Drive Power Amplifier: The high-current output stage (often a separate card or module in the same chassis) that receives the conditioned signal from the DS3826-SSHRBCA and drives the servo valve coil.

Servo Valve / Actuator: The final control element (e.g., a Moog servo valve) that physically positions the fuel rack or valve, controlled by the loop managed by the DS3826-SSHRBCA.

LVDT/RVDT Position Transmitter: Provides the precise mechanical position feedback of the actuator back to the DS3826-SSHRBCA board to close the control loop.

Mark IV Software & Tools: Legacy GE engineering tools used to configure and calibrate the servo loops involving the DS3826-SSHRBCA board.

Installation, Maintenance, and Full-Cycle Support

Installation of the DS3826-SSHRBCA is a precise task for qualified technicians. The turbine must be offline, and all system power must be isolated and locked out/tagged out (LOTO). The board is typically installed in a specific slot within a servo drive chassis. Careful attention must be paid to electrostatic discharge (ESD) protection, correct orientation, and ensuring all connectors are fully seated. After installation, loop calibration and functional testing are mandatory before returning the turbine to service. This includes verifying command/feedback tracking and checking for proper response.

Maintenance for such legacy boards is primarily reactive or condition-based. Given the age of Mark IV systems, proactive stocking of critical spares like the DS3826-SSHRBCA is a prudent strategy. Troubleshooting often involves using the system’s diagnostics, schematic diagrams, and a multimeter/oscilloscope to trace signals through the board’s test points. Our support is tailored for legacy systems. We provide fully tested and certified DS3826-SSHRBCA boards, often sourced from decommissioned systems or through specialist refurbishment partners. We can also provide technical guidance on compatibility, installation checks, and basic signal verification to help you maintain your critical turbine controls effectively and cost-efficiently.