Description:

Description:

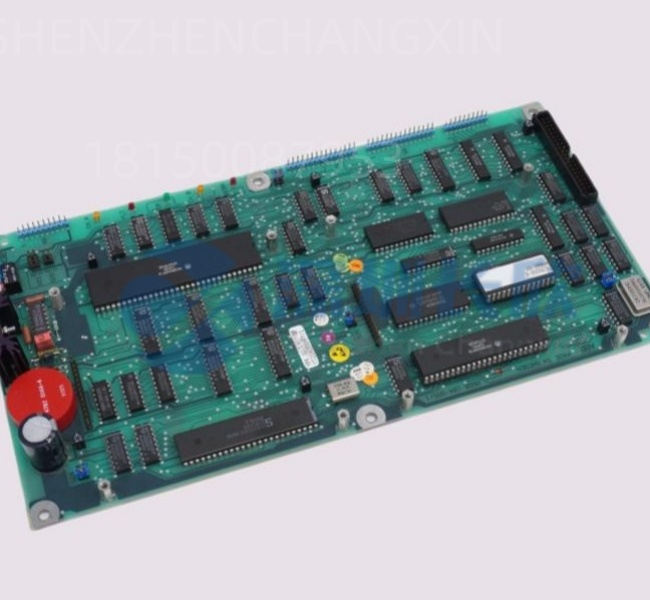

The GE IC660ELD100A is a 16-point, 24VDC sinking discrete input module for the GE Fanuc Series 90-30 Programmable Logic Controller (PLC) system. This module serves as a critical interface, connecting field devices like pushbuttons, limit switches, and proximity sensors to the PLC’s central processing unit, enabling it to monitor the state of machines and processes.

Application Scenarios:

On a high-speed automotive assembly line, dozens of pneumatic cylinders, indexing tables, and welding robots must operate in a perfectly synchronized sequence. A single misaligned part or a failed clamp can cause a major collision. The control system, built on a GE Series 90-30 PLC, needs to know the precise position of each actuator. This is where the GE IC660ELD100A modules are deployed. One module might be dedicated to a clamping station, with its 16 inputs wired to magnetic proximity sensors on each clamp. Each sensor’s 24VDC signal (sinking type) is read by the GE IC660ELD100A, which communicates the “clamp open” or “clamp closed” status to the PLC CPU. The logic program waits for the “all clamps closed” signal from the GE IC660ELD100A before allowing the robot weld cycle to begin. This reliable, high-speed input scanning directly solves the pain point of machine sequencing and safety interlocking, preventing costly damage and ensuring smooth, uninterrupted production flow.

Parameter:

Technical Principles and Innovative Values:

The GE IC660ELD100A embodies a robust and efficient design philosophy for industrial I/O:

Innovation Point 1: High-Density, Space-Efficient Design. In the era of the Series 90-30. packing 16 optically isolated input channels into a single module slot was a significant advantage. This density allowed control engineers to maximize I/O point count within a limited rack space, reducing the number of racks needed for large applications and lowering overall system cost and complexity.

Innovation Point 2: Robust Sinking Input Circuitry. The module uses a sinking input configuration, a common and reliable industrial standard. In this design, the field device (e.g., sensor) provides the 24VDC source. When the device is active, it allows current to flow intothe GE IC660ELD100A input point, completing the circuit to the internal common. This design offers excellent noise immunity and is compatible with a vast array of PNP-type industrial sensors.

Innovation Point 3: Optical Isolation for System Integrity. Each input channel on the GE IC660ELD100A incorporates optical isolation. This means the field-side wiring (connected to noisy machinery) is electrically separated from the sensitive logic-side electronics (connected to the PLC backplane) by an internal LED and phototransistor. This critical feature prevents transient voltage spikes, ground loops, and electrical noise on the factory floor from damaging the PLC’s CPU or causing erratic operation.

Innovation Point 4: Seamless Integration with 90-30 Ecosystem. The module is designed for plug-and-play operation within the Series 90-30 rack. It automatically identifies itself to the CPU upon insertion, and its I/O points are seamlessly mapped into the PLC’s memory (%I addresses) for programming in Logicmaster 90 or Proficy Machine Edition. The per-point LEDs provide instant visual diagnostics for troubleshooting.

Application Cases and Industry Value:

A municipal water treatment plant using a GE 90-30 PLC for filter backwash control experienced periodic, unexplained system halts. The issue was traced to intermittent signals from old, corroded limit switches indicating valve positions. The signals were unreliable due to minor voltage drops across long wire runs. The plant standardized on modern 3-wire DC proximity sensors and used GE IC660ELD100A modules for all new digital inputs. The IC660ELD100A’s precise input threshold and optical isolation provided a clean, stable signal to the PLC despite the long cable distances. Furthermore, during commissioning, a wiring error shorted a 120VAC line to a 24VDC input circuit. The optical isolation in the GE IC660ELD100A sacrificed only the single affected channel, protecting the entire rack and CPU from damage. The module’s robust design prevented a minor wiring mistake from causing a major system failure and expensive downtime. The GE IC660ELD100A delivered value by providing a reliable, fault-tolerant interface that turned noisy real-world signals into rock-solid data for the PLC, ensuring consistent, automated plant operation.

Related Product Combination Solutions:

GE IC660ELC100 / IC660ELC110: 16-Point 120VAC or 24VDC SourcingInput Modules, offering the complementary input style to the sinking GE IC660ELD100A.

GE IC660ELB100 / IC660ELB110: 16-Point 24VDC or 120VAC SourcingOutput Modules, used to control devices like solenoid valves and motor starters based on logic using inputs from the GE IC660ELD100A.

GE IC660EBS100: 90-30 Backplane, the mounting rack that houses the CPU, power supply, and I/O modules like the GE IC660ELD100A.

GE IC660CBLxxxx Series: Ribbon cables used to connect the GE IC660ELD100A module to its corresponding terminal board (TB) for field wiring.

GE IC660TBD100 / IC660TBT100: Terminal Boards (DIN-rail or panel mount) that provide the screw terminals for field device wiring connected to the GE IC660ELD100A.

GE Series 90-30 CPU (e.g., IC693CPU350): The central processing unit that reads the input status from the GE IC660ELD100A and executes the control program.

Proximity Sensors, Limit Switches, Pushbuttons: The field devices that provide the 24VDC sinking signals read by the GE IC660ELD100A input points.

Installation, Maintenance, and Full-Cycle Support:

Installation of the GE IC660ELD100A is straightforward within the 90-30 system. The module is keyed and plugs directly into a slot on the backplane. The corresponding terminal board (TB) is mounted on a DIN rail or panel, and field devices are wired to its terminals. A ribbon cable then connects the terminal board to the module. Correct wiring of the 24VDC common and input points is crucial. Configuration is automatic; the CPU identifies the module, and the user simply addresses the inputs (e.g., %I0001 – %I0016) in the PLC programming software.

Maintenance is minimal. The primary diagnostic tool is the row of LED indicators on the module, showing the real-time status of each input. Routine checks involve verifying that the LED state matches the expected state of the field device. If a point fails, the optically isolated design typically contains the fault. Replacement is simple: power down the rack, disconnect the ribbon cable, remove the old module, and insert the new GE IC660ELD100A. The module’s durability and simple design contribute to a long service life. We provide comprehensive support for this legacy yet widely used component, from supplying tested modules to assisting with wiring diagrams and integration into your existing 90-30 system.