Description

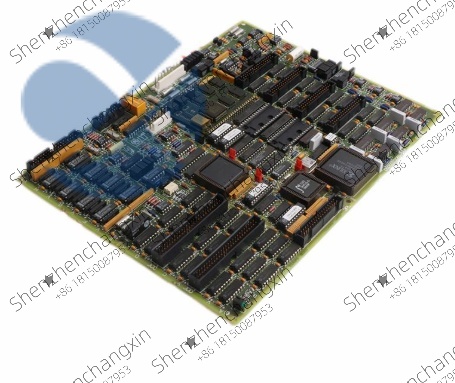

The GE IC693CPU372is a high-performance programmable logic controller CPU module from GE’s Series 90-30 system,designed for mid-range industrial automation applications requiring robust processing power and reliable operation.This advanced processor combines substantial memory capacity with fast execution speeds,making it suitable for complex control tasks in manufacturing,process control,and infrastructure automation where operational reliability and processing performance are critical requirements.

Application Scenarios

In a large automotive assembly plant’s paint shop,multiple GE IC693CPU372controllers coordinate robotic painting systems and conveyor synchronization with precision timing requirements.A recent system upgrade utilizing IC693CPU372processors reduced cycle times by 15%while maintaining 99.98%operational availability over two years of continuous production.The automation engineer reported:”The IC693CPU372’s processing speed and reliability have been essential for maintaining our production throughput while reducing system complexity.”

Parameter

Main Parameters

Value/Description

Product Model

IC693CPU372

Manufacturer

General Electric(GE)

Product Type

PLC Processor Module

Processor Speed

20MHz

User Memory

256K bytes

Data Memory

128K bytes

I/O Capacity

1024 points

Scan Time

0.5ms/K

Communication Ports

RS-232,RS-485

Real-Time Clock

Battery-backed

Battery Life

5 years typical

Operating Temperature

0°C to+60°C

Power Supply

5V DC from backplane

Certifications

UL,cULus,CE

Technical Principles and Innovative Values

Advanced Processing Architecture:The GE IC693CPU372utilizes a 20MHz processor with optimized instruction set specifically designed for industrial control applications.The processor’s architecture enables efficient execution of ladder logic,function block diagrams,and structured text programming,providing flexibility for various application requirements while maintaining deterministic scan times essential for real-time control.

Comprehensive Memory Management:With 256K bytes of user memory and 128K bytes of data memory,the IC693CPU372supports complex control programs and extensive data handling requirements.The battery-backed memory ensures program retention during power outages,while the error detection and correction mechanisms maintain data integrity in electrically noisy industrial environments.

Robust Communication Capabilities:Featuring both RS-232 and RS-485 communication ports,the processor supports multiple industrial protocols including SNP and Modbus.The IC693CPU372’s communication processor handles network traffic independently,ensuring control program execution is not impacted by communication activities,maintaining consistent scan times even during high network utilization.

Integrated Diagnostics:The processor incorporates comprehensive self-diagnostic functions that monitor system health,including power supply status,memory integrity,and I/O communication.The GE IC693CPU372provides detailed fault information through status indicators and programming software,enabling quick troubleshooting and reduced downtime.

Application Cases and Industry Value

In a municipal water treatment facility,GE IC693CPU372controllers manage chemical dosing and filtration processes across multiple treatment trains.The installation has operated continuously for over 60,000 hours with 99.95%availability,successfully maintaining water quality compliance while reducing chemical usage by 12%through advanced control algorithms.The system’s reliability has enabled predictive maintenance scheduling,reducing unplanned downtime by 40%annually.

Related Product Combination Solutions

GE IC693PWR321|Power supply module

GE IC693ACC300|5-slot CPU rack

GE IC693MDL654|32-point digital I/O

GE IC693ALG220|Analog input module

GE IC693CMM301|Communication module

GE IC697ACC728|Expansion rack interface

GE VersaMax I/O|Distributed I/O system

Installation and Maintenance

Installation Preparation:Proper installation of the GE IC693CPU372requires verification of compatible rack systems and adequate power supply capacity.The CPU must be installed in slot 0 of the Series 90-30 rack with proper grounding and secure mounting.Ensure all communication cables are properly routed and secured to prevent electromagnetic interference.

Maintenance Recommendations:Regular maintenance includes quarterly battery voltage checks and annual program backups.Monitor CPU diagnostics through programming software and maintain firmware updates.Keep ventilation paths clear and maintain operating temperature within specified limits to ensure optimal performance.

Technical Support:We provide comprehensive technical support for IC693CPU372systems,including configuration assistance and troubleshooting services.Our inventory includes certified replacement modules with guaranteed compatibility for rapid deployment.

Contact us for expert assistance in implementing GE IC693CPU372programmable controller solutions for your industrial automation requirements.Our technical team can provide customized programming and configuration support tailored to your specific application needs.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

.jpg)