Description

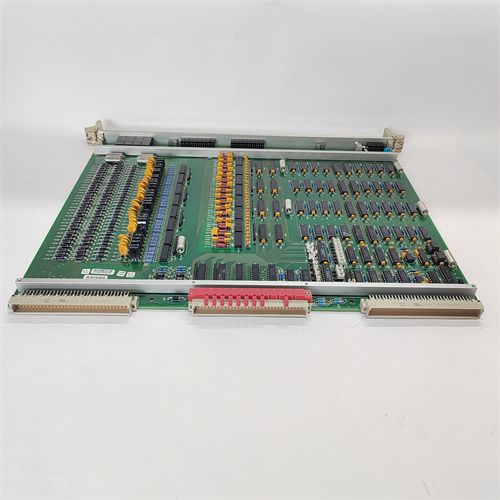

GE IC698CPE010-JUis a high-performance PACSystems RX7iCentral Processing Unit(CPU)module manufactured by GE Intelligent Platforms(now part of Emerson).This controller represents a core component in the RX7i series,designed to handle demanding control,logic,and data processing tasks for complex industrial automation and process control applications.It combines a powerful processor with integrated Ethernet connectivity to serve as the central intelligence for large-scale distributed control systems.

Application Scenarios

Consider a sprawling wastewater treatment plant where the control system must manage thousands of I/O points across primary clarification,aeration basins,secondary clarifiers,and disinfection channels.The system requires fast,deterministic logic execution for pump sequencing and valve control,complex PID loops for dissolved oxygen and chemical feed control,seamless data exchange with remote I/O racks over a VME backplane,and robust communication with a plant-wide SCADA system via Ethernet.The legacy PLC-based system is struggling with scan time,memory limitations,and network integration.Migrating to a GE IC698CPE010-JUPACSystems RX7i CPU addresses these pain points directly.Its 700 MHz processor and 10 MB user memory can consolidate control from multiple older PLCs,dramatically improving system-wide response times and enabling advanced control strategies.The dual embedded Ethernet ports allow for the creation of a segregated network—one dedicated to engineering and SCADA traffic and the other for peer-to-peer controller communication or connection to enterprise systems.A plant engineer reported,”Replacing our aging PLCs with a single RX7i rack using the IC698CPE010-JUas the master controller simplified our architecture,cut our worst-case scan time by 60%,and gave us the data handling capacity to implement advanced nutrient removal algorithms we couldn’t run before.The Ethernet connectivity made integrating our new historian effortless.”

Parameter

Main Parameters

Value/Description

Product Model

IC698CPE010-JU

Manufacturer

GE Intelligent Platforms(Emerson)

Product Category

Programmable Automation Controller(PAC)CPU Module

Processor Speed

700 MHz

User Memory

10 MB(for logic,variables,storage)

Integrated Ethernet

2 ports,10/100 Mbps,auto-sensing,auto-MDIX

Serial Port

1 RS-232/RS-485 configurable serial port

Backplane Communication

VME64(to RX7i I/O and Genius Communications)

Discrete I/O Capacity

Up to 12,288 points(mix of local and remote)

Analog I/O Capacity

Up to 4096 points

Typical Scan Time

0.09 ms/K typical(depends on logic complexity)

Battery Backup

For real-time clock and RAM retention

Programming Software

PACSystems Machine Edition(PME)

Technical Principles and Innovative Values

Innovation Point 1:Unified Architecture with Portable Code

The IC698CPE010-JUis a cornerstone of GE’s”Universal Control”PACSystems architecture.Its most significant innovation is the use of a common,hardware-independent instruction set and development environment(PME).This means control logic created for the RX7i platform is portable to other PACSystems families like the RX3i,protecting software investment from hardware obsolescence.The CPU executes this logic on its powerful 700 MHz processor,providing the deterministic performance required for high-speed machine and process control.This separation of application software from the hardware runtime environment is a key differentiator,offering unparalleled long-term flexibility and reducing lifecycle costs.

Innovation Point 2:Dual Embedded Ethernet for Network Segmentation and Resilience

The inclusion of two auto-sensing 10/100 Mbps Ethernet ports on the CPU module itself is a strategic advantage.It allows engineers to design robust network topologies without requiring additional communication modules.Typically,one port is dedicated to the plant information/SCADA network for HMI,historian,and MES/ERP connectivity,while the second port is used for a separate control network for peer-to-peer CPU messaging,distributed I/O(using SRTPprotocol),or connection to drives and other intelligent devices.This physical segmentation enhances security and performance by isolating control traffic from business network traffic,and provides redundancy options for critical communications.

Innovation Point 3:High-Density I/O Management and Scalability

The IC698CPE010-JUleverages the high-speed VME64 backplane of the RX7i platform to manage a vast I/O footprint.It can support a large local rack of high-density I/O modules and act as a master to numerous remote Genius LANs or Ethernet-based I/O.This scalability allows it to serve as the central controller for extremely large applications,replacing multiple smaller PLCs.Its 10 MB of user memory supports complex programs,extensive data table storage for recipe management,and sophisticated alarm and event handling,making it suitable for both discrete manufacturing and continuous process control.

Application Cases and Industry Value

Case Study:Modernizing a Steel Mill Finishing Line

A major steel producer needed to upgrade the control system for its hot-dip galvanizing line.The existing system,composed of multiple,aging PLC-5 and 90-30 controllers,suffered from slow line coordination,difficulty in implementing new product grade recipes,and excessive maintenance downtime due to obsolete parts.The goal was to increase line speed,improve coating consistency,and gain better production data visibility.

The solution centered on a new control cabinet built around a PACSystems RX7i with the IC698CPE010-JUCPU.The powerful CPU consolidated the logic from over a dozen older PLCs.It now directly controls the line tension,furnace zones,zinc pot temperature,air knife positioning,and the passline automation.The dual Ethernet networks were key:Network A connects to the mill-wide SCADA for production scheduling and reporting,while Network B handles high-speed,deterministic communication with distributed I/O blocks along the 300-meter line and the variable frequency drives.

The results were substantial:1.15%Increase in Line Speed:Faster scan times and optimized control algorithms allowed for higher throughput without sacrificing quality.2.30%Reduction in Galvanizing Defects:Precise,coordinated control of the process variables by a single CPU minimized variations,leading to a more uniform coating.3.50%Faster Product Changeovers:The large memory of the IC698CPE010-JUenabled the storage of hundreds of detailed recipes,which could be loaded and executed instantly.The mill’s engineering manager noted,”The IC698CPE010-JUgave us the processing muscle and networking backbone we needed.It’s not just a controller;it’s the central nervous system that made our line smarter,faster,and more reliable.The investment paid for itself in under 18 months through yield improvement and reduced downtime.”

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!