Description

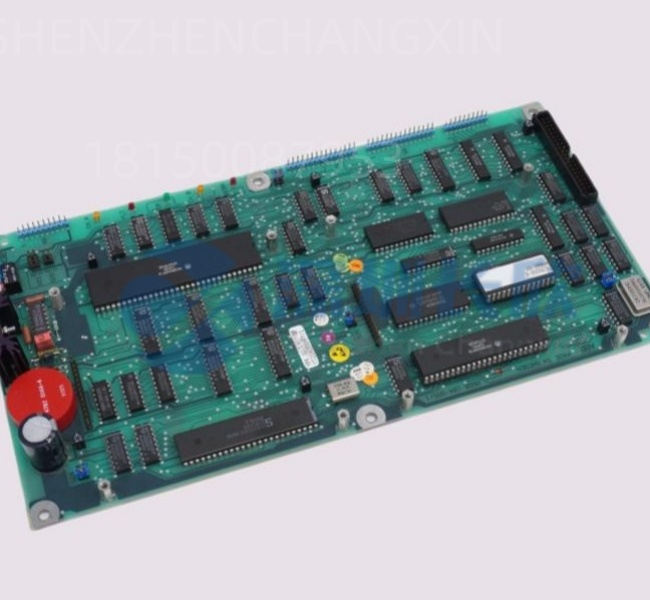

The GE IS200BPPBH2CAA is a critical power distribution backplane module within General Electric’s Mark VIe turbine control architecture.It serves as the central power routing and conditioning interface for I/O terminal boards(such as TBSA,TDSA,or TSVCH),delivering stable,fused,and monitored 24 VDC to all connected I/O modules in a redundant or simplex configuration.

More than just a passive carrier,the GE IS200BPPBH2CAA integrates intelligent fuse status detection,dual power input support,and robust overcurrent protection—ensuring that even in the event of a localized fault,the integrity of the entire I/O rack remains uncompromised.

Application Scenarios

At a 700 MW natural gas peaker plant in California,intermittent I/O dropouts during summer peak loads traced back to undetected fuse degradation on legacy power backplanes.After upgrading to the GE IS200BPPBH2CAA,operators gained real-time visibility into fuse health via the Mark VIe diagnostic system.During a subsequent grid emergency,one power feed failed—but thanks to the module’s seamless redundancy and automatic load transfer,zero I/O channels were lost,allowing the turbine to remain online and support grid stability.In this moment,the GE IS200BPPBH2CAA proved that reliable power distribution is not infrastructure—it’s insurance against blackouts.

Parameter

Main Parameters Value/Description

Product Model GE IS200BPPBH2CAA

Manufacturer General Electric(GE Power/Bently Nevada)

Product Category I/O Power Distribution Backplane(Mark VIe System)

Primary Function Distributes and monitors 24 VDC power to I/O terminal boards

Power Inputs Dual isolated 24 VDC inputs(Redundant A/B paths)

Fuse Configuration 8 x fast-acting,field-replaceable fuses(typically 2A–4A per zone)

Fuse Monitoring Yes—each fuse status reported via discrete dry contacts to controller

Backplane Connectors Compatible with IS200TBSAH1B,IS200TDSAH1B,IS200TSVCH1B,etc.

Diagnostic Indicators Per-fuse LED(green=OK,red=blown)+power-good LEDs

Mounting Type Vertical mount in Mark VIe I/O chassis(standard 19″rack compatible)

Operating Temperature 0°C to+60°C(convection-cooled,no fans)

Safety Certification IEC 61508 SIL 3(when used in certified safety loops),CE,UL 61010-1

Redundancy Support Full 1+1 power redundancy with automatic failover

Technical Principles and Innovative Values

Innovation Point 1:Active Fuse Health Monitoring

Unlike passive fuse blocks,the GE IS200BPPBH2CAA uses opto-isolated sensing circuits to detect open fuses instantly and report their status to the Mark VIe controller—enabling predictive maintenance before an I/O channel fails.

Innovation Point 2:True Dual-Path Power Isolation

The two 24V inputs are galvanically isolated from each other,preventing ground loops and ensuring that a short on one supply does not compromise the backup—a critical feature in SIL 3 turbine trip systems.

Innovation Point 3:Modular&Serviceable Design

Fuses are mounted in pull-out carriers with clear labeling,allowing hot replacement without de-energizing the entire rack.Combined with front-access LEDs,this reduces MTTR to under 2 minutes.

Innovation Point 4:Electromagnetic Hardening for Turbine Environments

The GE IS200BPPBH2CAA features multi-stage filtering and conformal-coated PCBs to withstand EMI from exciters,VFDs,and breaker operations—common causes of nuisance trips in older systems.

Application Cases and Industry Value

In a Middle Eastern combined-cycle plant,a recurring“false”fuel valve closure alarm was disrupting automated startups.Root-cause analysis revealed a marginal fuse on the old backplane causing voltage sag under load.After installing the GE IS200BPPBH2CAA,the fuse monitoring system flagged a similar issue during commissioning—before it caused an outage.Over the next year,unplanned combustion turbine trips dropped by 60%,directly linked to improved I/O power integrity.

Similarly,at a European district heating facility using a steam turbine with Mark VIe control,the GE IS200BPPBH2CAA enabled compliance with EN 62061 by providing verifiable,redundant power paths for emergency stop circuits.Auditors accepted the fuse status telemetry as proof of continuous safety function integrity—accelerating certification by three weeks.

Related Product Combination Solutions

GE IS200TBSAH1B:Terminal board for analog inputs,powered via GE IS200BPPBH2CAA

GE IS200TDSAH1B:Discrete I/O terminal base,requiring clean 24V from GE IS200BPPBH2CAA

GE IS200TSVCH1B:High-density terminal board for pulse/discrete signals,fully supported by GE IS200BPPBH2CAA

GE IS220PDIAH1B:32-channel input module that plugs into terminal boards powered by GE IS200BPPBH2CAA

GE IS220UCSAH1A:Mark VIe controller that reads fuse status from GE IS200BPPBH2CAA via IONet

GE IC698PSD300:While part of PACSystems,often used in balance-of-plant cabinets with similar backplane logic

GE IS200PCCDH1A:Power conversion module that can feed the dual inputs of GE IS200BPPBH2CAA for full redundancy

Installation,Maintenance,and Full-Cycle Support

Installation of the GE IS200BPPBH2CAA requires secure mounting in the Mark VIe I/O chassis and connection of two independent 24 VDC sources(typically from IS200PCCDH1A or external redundant PSUs).Ensure proper torque on fuse terminals(0.5 N·m)and verify polarity before energizing.During startup,confirm all green“Power Good”LEDs illuminate and that no fuse alarms appear in ToolboxST.

For maintenance,perform quarterly visual inspections of fuse LEDs and use the Mark VIe HMI to log historical fuse events.Replace suspect fuses using the pull-tab carriers—no tools required.If both power inputs fail simultaneously,investigate upstream power supplies before assuming backplane fault.

We supply only genuine GE IS200BPPBH2CAA units,each tested for continuity,isolation(>5 MΩ),and fuse monitoring accuracy.Every module includes original factory labels,test records,and compatibility verification with Mark VIe firmware versions.Our support team provides wiring diagrams,redundancy validation checklists,and rapid cross-reference assistance for legacy Mark VI upgrades.

UFC921A101 3BHB024855R0101 UFC911B106 3BHE037864R0106 UDC920BE01 3BHE034863R0001 XVC770BE101 3BHE021083R0101 KUC755AE105 3BHB005243R0105 LXN1604-6 3BHL000986P7000 LWN2660-6E 3BHL000986P7002 UFC789AE 38HE014022P102 3BHL000734P0003 SLOV4.6/5.3 HIES308461R0012 HIES208441R.. ID8A92485001/022 3BHB009410R000 SG000247 3BHL000986P1006 XVC724BE101 3BHE009017R0102 DKTFM418B 3BHB015651P0001 PU180/63E 3BHB00916230001 HIES308461R0012 FPX86-9345–B 3BHL000986P0006 3BHL000734P0003 SLOV4.6/5.3 UFC921A101 3BHE024855R0101 PPC907BE101 3BHE024577R0101 XVC724BE101 3BHE009017R0102 IEC60129,62271-102 MI-CONP KUC755AE105 3BHB005243R0105 HIES308461R0012 MG160MD2-42FF300-F1 PTC 160℃ TP211 MG160MD2-42FF300-F1 ABB S-073N ALU 3BHB009884R5211 ABB S-093H 3BHB030478R0309 ABB S-123H 3BHB030479R0512 ABB UFC912A101 3BHE039426R0101 ABB 5SHY4045L0001 3BHB018162R0001 ABB S-113N 3BHB018008R0001 W4 KUC755AE105 3BHB005243R0105 HIEE401807R0001 3BHB046719R0008 STRAUB FLEX1L TB820V2 S-053M 3BHB012897R003 *12 3BHB014556R0001 3BHB010823R0002 CDP312R XVC768AE102 UFC789AE101 S-073N KU C755AE105 XVC770BE101 UFC760BE42 PPC907BE UFC760BE43 XVC769AE101 LDMTR-01 UAC389AE02 LTC391AE01 PPC905AE101 UAC383AE01 LDLPTR-01